Novel preparation technique for poly (p-phenylene terephthalamide)

A technology of poly-p-phenylene terephthalamide and terephthaloyl chloride, which is applied in the field of manufacturing poly-p-phenylene terephthalamide resin, can solve the requirements of particle size and environmental humidity requirements, and operation Unfriendly to the environment and other issues, to achieve the effect of fresh color, friendly production environment, and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

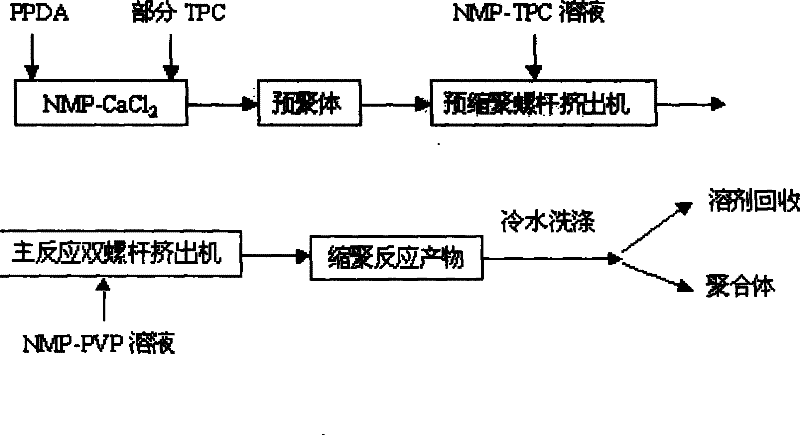

[0035] In a 250L jacketed stainless steel reactor, inject 7% calcium chloride (CaCl 2 ) 200 kg of N-methylpyrrolidone (NMP) solution, add 8.020 kg of p-phenylenediamine (PPDA) at 15°C to fully dissolve it, and make NMP-CaCl 2 - After the PPDA solution, cool to below 0°C, slowly add 12.060 kg of terephthaloyl chloride (TPC), react for 20 minutes to form a prepolymer, and prepolymer and 50wt% NMP-TPC solution are respectively mixed at 1000g / min and 27.40g / min are simultaneously pumped into a twin-screw extruder with a diameter of Φ50, an aspect ratio of 15, and a rotational speed of 200rpm, and the temperature of the precondensation reaction is controlled at 15-25°C. , length-to-diameter ratio is 50, rotating speed is in the twin-screw extruder of 90rpm, and in its third section, drop 50% NMP-PVP (polyvinylpyrrolidone) with 8g / min, control main polycondensation reaction screw extruder The temperature is 60-80°C, about 20 minutes, extrude the light yellow powder polycondensation...

Embodiment 2

[0037] In a 250L jacketed stainless steel reactor, inject 6% calcium chloride (CaCl 2 ) 200 kg of N-methylpyrrolidone (NMP) solution, add 8.020 kg of p-phenylenediamine (PPDA) at 15°C to fully dissolve it, and make NMP-CaCl 2 -After the PPDA solution, cool to below 0°C, slowly add 7.575 kg of terephthaloyl chloride (TPC), react for 20 minutes to form a prepolymer, and prepolymer and 50wt% NMP-TPC solution are respectively mixed with 898.3g / min and 62.5g / min are simultaneously pumped into a twin-screw extruder with a diameter of Φ50, an aspect ratio of 15, and a rotational speed of 200rpm. The temperature of the precondensation reaction is controlled at 15-25°C. In the twin-screw extruder with Φ65, aspect ratio of 50 and rotating speed of 90rpm, add 50% NMP-PVP (polyvinylpyrrolidone) dropwise at 10g / min in the third section to control the main polycondensation reaction screw extrusion The temperature of the machine is 60-80°C, about 20 minutes, extrude the light yellow powder...

Embodiment 3

[0039] In a 250L jacketed stainless steel reactor, inject 6% calcium chloride (CaCl 2 ) 200 kg of N-methylpyrrolidone (NMP) solution, add 8.020 kg of p-phenylenediamine (PPDA) at 15°C to fully dissolve it, and make NMP-CaCl 2 -After the PPDA solution, cool to below 0°C, slowly add 12.060 kg of terephthaloyl chloride (TPC), react for 20 minutes to form a prepolymer, and prepolymer and 30wt% NMP-TPC solution are respectively mixed at 1000g / min and 45.67g / min are simultaneously pumped into a twin-screw extruder with a diameter of Φ50, an aspect ratio of 15, and a rotational speed of 200rpm, and the temperature of the precondensation reaction is controlled at 15-25°C. , length-to-diameter ratio is 50, rotating speed is in the twin-screw extruder of 90rpm, and in its third section, drop 50% NMP-PVP (polyvinylpyrrolidone) with 10g / min, control main polycondensation reaction screw extruder The temperature is 60-80°C, for about 20 minutes, extrude the light yellow powder polycondensa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com