Method for recycling waste liquor of ammonium hexanedioic acid and recycling system thereof

A recovery method, ammonium adipate technology, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylic acid salts, etc., can solve problems such as recycling and utilization of waste electrolyte, and achieve remarkable results , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

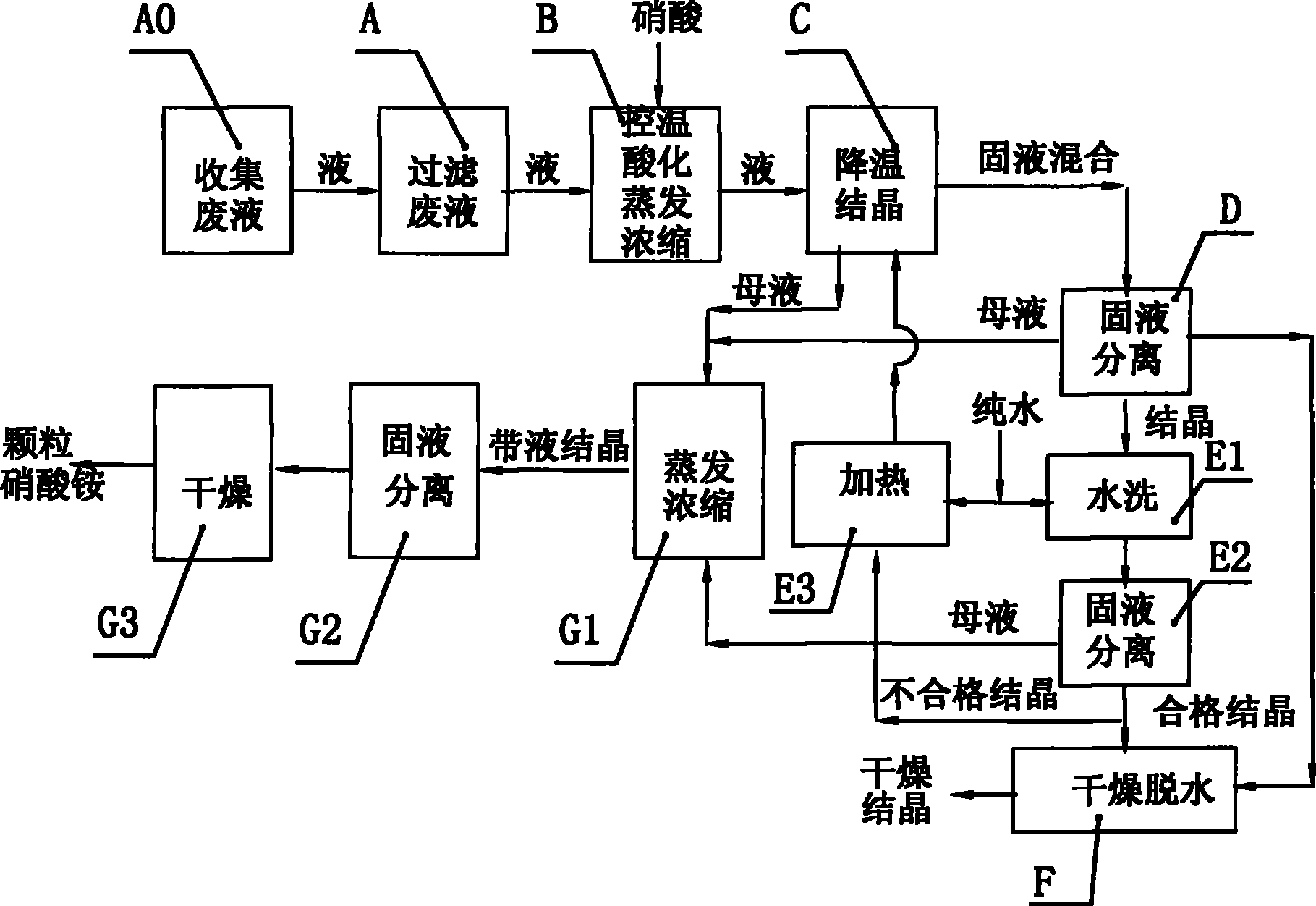

[0028] System embodiment:

[0029] As shown in Fig. 1, it is the structural representation of ammonium adipate waste liquid recovery system of the present invention. It includes the following components directly or indirectly connected to the main inlet / outlet: waste liquid tank 10, filter 11, acidifier 12 with heating device, temperature-controlled crystallizer 13, solid-liquid separator 1-14A, water washing Groove 15, solid-liquid separator 2-14B, draft drier 16, between solid-liquid separator 2-14B and temperature control crystallizer 13, also be installed with the heater 17 for recrystallization, be used for checking unqualified Carry out recrystallization and purification after the crystals are melted; there is also a pipeline T with a switching valve between the solid-liquid separator 1-14A and the suction dryer 16, which is used to directly transport the recrystallized liquid crystals obtained after recrystallization to The solid-liquid separator 1-14A performs one-tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com