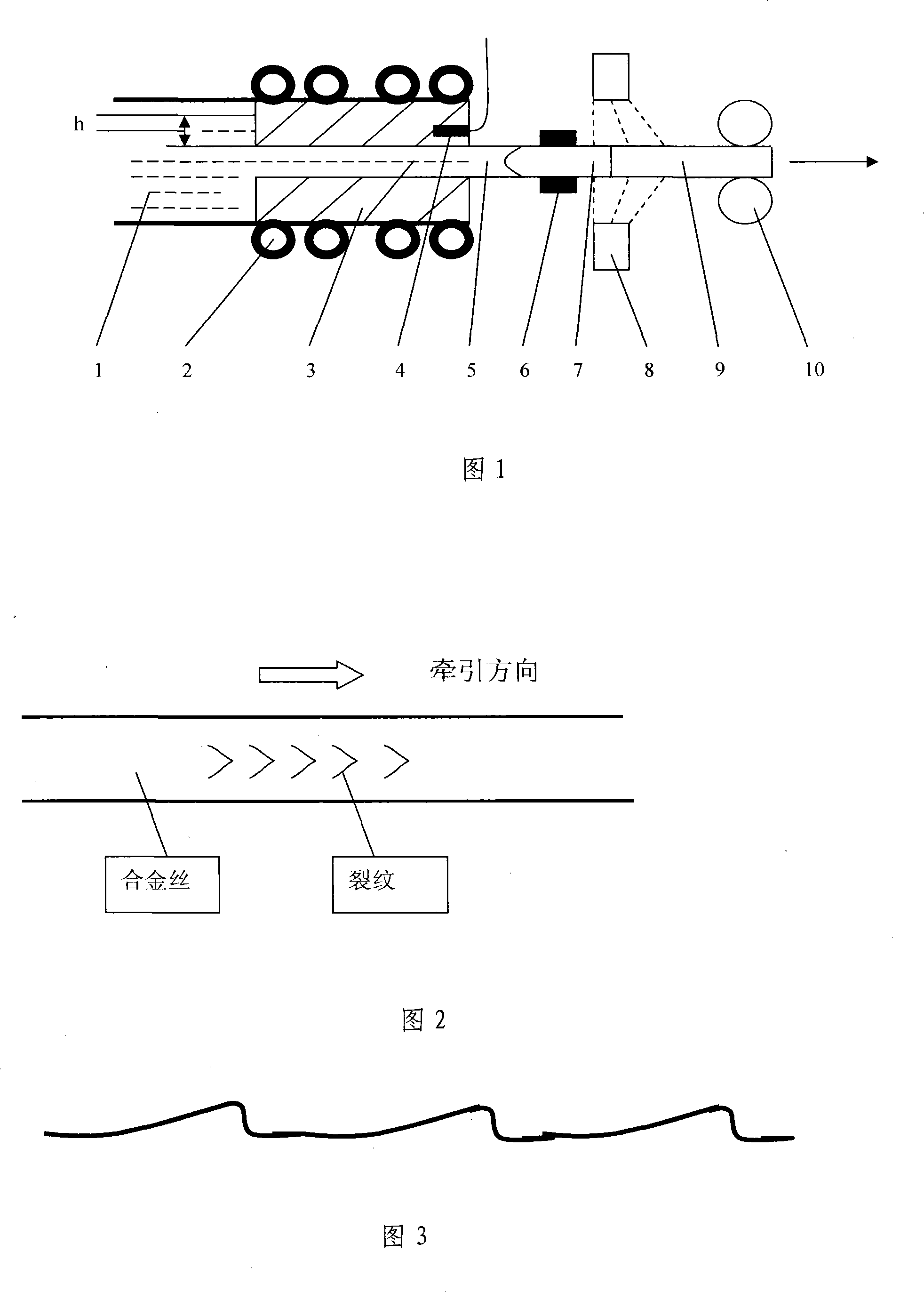

Apparatus and method for continuously casting copper base shape memory alloy wire

A technology of memory alloy wire and alloy wire, which is applied in the field of equipment for continuous casting of copper-based shape memory alloy wire, and can solve problems such as alloy wire cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, a Cu-Al-Ni alloy containing 13.95 wt% of Al, 3.95 wt% of Ni and the remainder being Cu is continuously cast at a speed of 240 mm / min into a wire with a diameter of 0.7 mm. The distance h between the liquid level of the alloy liquid 1 and the molding cavity of the mold 3 is 30mm, the temperature of the mold is set at 1100°C, and the distance between the cooler and the mold is 5mm. Metallographic examination showed columnar grain structure. Alloy wire is super elastic. The number of bending fatigue fractures in the as-cast state is 16,000 times, and the number of bending fatigue fractures after solution treatment is 14,000 times.

Embodiment 2

[0033] In this embodiment, a Cu-Al-Ni alloy containing 13.22wt% Al, 3.95wt% Ni, and the remainder being Cu is continuously cast into wires with a diameter of 1mm at a speed of 108mm / min. The distance h between the liquid level of the alloy liquid 1 and the molding cavity of the mold 3 is set to 20mm, the mold temperature is set to 1075°C, and the distance between the cooler and the mold is 13mm. The alloy wire has shape memory properties, and the metallographic examination shows that it is a columnar grain structure. After solution treatment, under a fixed strain of 4%, it is stretched and heated cyclically to restore its original length until fatigue fracture occurs. The highest number of stretches at break is 38560 times. The shape recovery rate after heating was 100% throughout the tensile test. It fully demonstrates that the memory alloy wire produced by the invention has excellent mechanical properties, memory properties and fatigue properties.

Embodiment 3

[0035] In this embodiment, a Cu-Al-Ni alloy containing 13.95wt% Al, 3.95wt% Ni and the remainder being Cu is cast at a speed of 500mm / min into a wire with a diameter of 2mm. The distance h between the liquid level of the alloy liquid 1 and the molding cavity of the mold 3 is set to 5mm, the mold temperature is set to 1050°C, and the distance between the cooler and the mold is 6mm. The alloy wire has superelasticity in the as-cast state. Metallographic examination shows that it is fine-grained columnar grain structure. The number of bending fatigue fractures in the as-cast state is 20,000 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com