Method for improving crush efficiency factor of hammer piece disintegrating machine

A crushing efficiency, pulverizer technology, applied in the direction of grain processing, etc., to achieve the effect of improving product sieving rate, improving striking efficiency and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

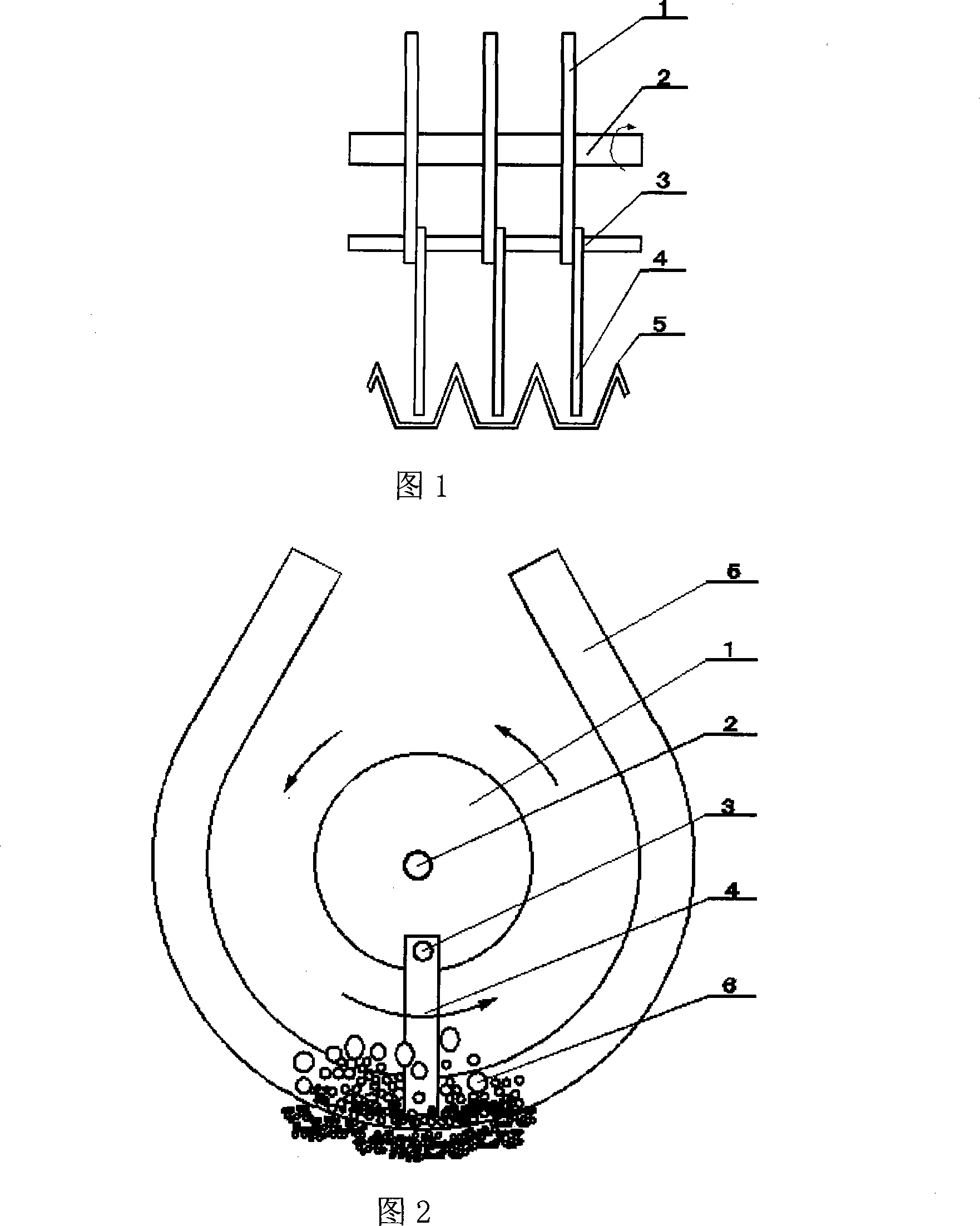

[0023] The invention provides a method for improving the crushing efficiency of a hammer mill. Figures 1 to 2 are schematic diagrams of the structure of a hammer mill. In the figure, the main shaft 2 is fixed on the frame of the hammer mill (not marked in the figure), the positioning plate 1 is fixed on the main shaft 2, and fixed with the hammer 4 through the connecting pin 3, and the sieve plate 5 is located under the hammer 4 , the hammer head part of the hammer 4 is just in the groove of the sieve plate 5, and the material 6 also just falls in the groove of the sieve plate 5.

[0024] The working process of the present invention: after the material 6 to be crushed enters the pulverizer, it will automatically enter the groove of the sieve plate 5 and be forcibly hit by the high-speed rotating hammer 4 (the high-speed rotating hammer 4 moves in the groove) ), the whole structure of the sieve plate 5 is composed of several grooves, the number of grooves on the sieve plate 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com