High efficient stripping method of current collector in lithium battery recycling

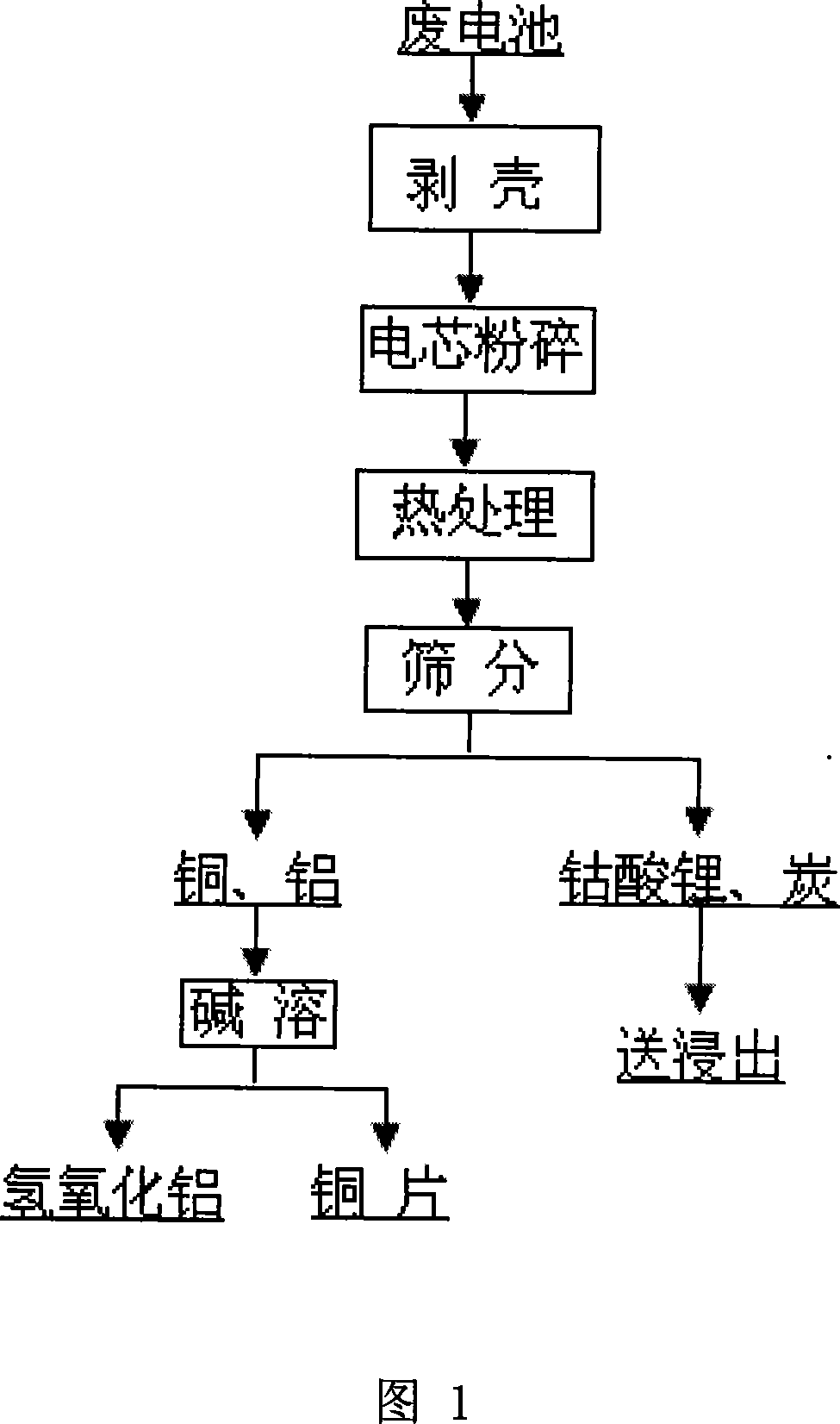

A technology for waste lithium batteries and current collectors, which is applied in the field of physical separation of waste lithium batteries, can solve the problems of low stripping efficiency of current collectors, poor stripping effects, and high stripping efficiency, and achieve improved disassembly efficiency, low cost, and high efficiency. The effect of efficiency recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: 10 kg of waste mobile phone lithium batteries were disassembled and shelled to obtain 2.64 kg of shells and 7.36 kg of battery cores. The battery core is crushed to 1-5 mm, heat treated at 450° C. for 2 hours, and the powder after heat treatment is sieved through 80 mesh vibration. The lithium cobalt oxide powder under the sieve is washed with 4% NaOH solution to remove a small amount of aluminum oxide, filtered and washed, and then sent to the leaching process for leaching. Dissolve the copper and aluminum flakes on the sieve with 3% solution, adjust the pH value to 8-9 with ammonium bicarbonate, precipitate white aluminum hydroxide, filter, wash and dry to obtain 1.47kg of aluminum hydroxide, and the recovery rate of aluminum is about 87.4%. 1-5 mm copper flakes are obtained from the filter residue after filtration, and 0.92 kg of high-quality red copper is obtained after melting into an ingot, and the copper recovery rate is 98.6%. A small amount of lithi...

Embodiment 2

[0012] Example 2: 1 ton of waste lithium-ion battery, the battery core is crushed to 1-5mm, heat treated at 250°C for 7 hours, and the powder after heat treatment is passed through 30-mesh vibrating sieve. The lithium cobalt oxide powder under the sieve is washed with 4% alkaline solution to remove a small amount of aluminum oxide, filtered and washed, and then sent to the leaching process for leaching. Dissolve the copper and aluminum flakes on the sieve with 4% alkaline solution, filter, adjust the pH value of the filtrate to 8-9 with ammonium bicarbonate, precipitate, filter, wash, and dry to obtain aluminum hydroxide; the filter residue is copper flakes of 1-5mm , After melting into ingots, high-quality red copper is obtained. A small amount of lithium cobalt oxide entrained by the copper sheet will go to the slag, and the slag will return to leaching to extract cobalt and lithium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com