Anode for lithium battery and lithium battery employing the same

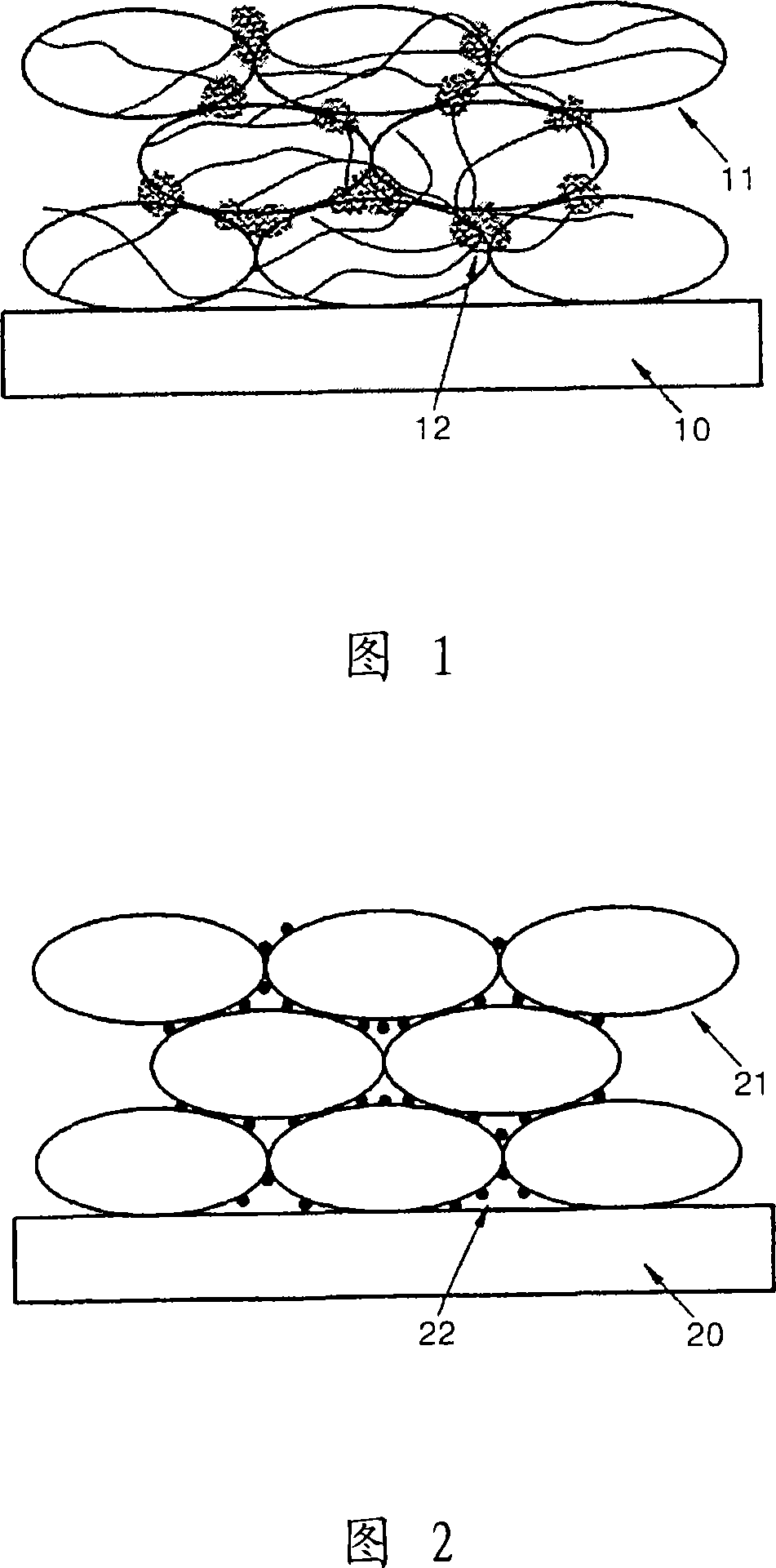

A lithium battery and negative electrode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, negative electrodes, etc., can solve the problems of electrode structure changes, reduced life of metal/graphite composite negative electrodes, weak adhesion, etc., to improve life characteristics, high energy density, effect of improving assembly density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] According to another embodiment of the present invention, a lithium battery includes the negative electrode. A lithium battery according to one embodiment is shown in FIG. 8 .

[0042] First, a positive electrode can be manufactured as follows. First, a positive active material, a conductive agent, a binder resin, and a solvent are mixed to prepare a positive active material composition. The positive active material composition was directly coated on a metal collector and dried to prepare a positive plate. Alternatively, the positive active material composition is casted on a separate support and dried to form a film, and then the film is separated from the support and laminated on a metal collector to prepare a positive plate.

[0043] The positive active material may be lithium-containing metal oxides generally used in the art. Non-limiting examples of suitable positive electrode active materials include LiCoO 2 , LiMn x o 2x (x=1, 2), LiNi 1-x mn x o 2x (whe...

Embodiment 1

[0055] 77 g of a negative electrode active material having a particle diameter of 20 μm (composite active material including graphite, silicon metal, and carbon obtained from Osaka Gas Chemical Co.) was mixed with 20 g of a conductive agent (graphite conductive agent obtained from Timcal Co., SFG6). 150 g of a 1% by weight sodium carboxymethylcellulose solution was added thereto and mixed to form a solution. 3.75 g of 40% by weight polyethylhexyl acrylate having a particle size of 0.25 μm was dispersed in water, and water was added to the solution and mixed to prepare a slurry having 200 g of water.

[0056] The prepared slurry was coated on a copper (Cu) current collector to a thickness of about 80 μm using a doctor blade. The coated current collector was dried in a hot air drier, and then dried again in vacuum at 120° C. to prepare an anode. The negative electrode was rolled to a thickness of about 50 μm using a roller to prepare a negative electrode plate.

Embodiment 2

[0058] A negative plate was prepared as in Example 1, except that 100 g of a 1% by weight sodium carboxymethylcellulose solution and 5 g of 40% by weight polyethylhexyl acrylate dispersed in water were used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com