Scanning electron microscope in situ electric measuring apparatus

An electron microscope and measuring device technology, applied in measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of the length of electrode nanowires and the inability to change the position of electrodes, poor in-situ real-time observation ability, and small structure of nanomaterials. To achieve the effect of selectivity, reliable performance and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

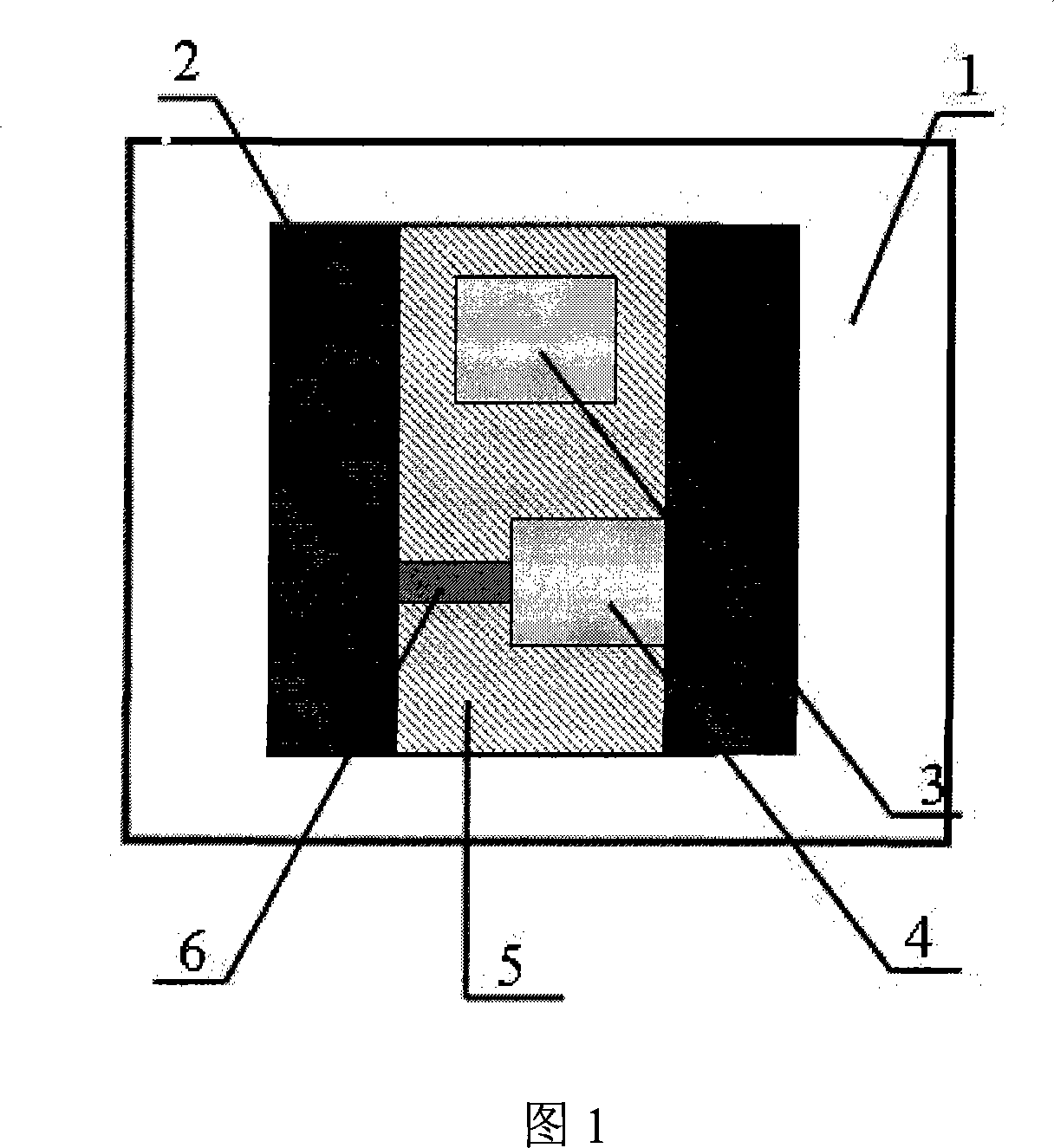

[0017] Below in conjunction with Fig. 1, the present invention will be further described:

[0018] Using a scanning electron microscope, it is possible to measure the electrical properties of micro-components under the condition of an applied electric field, observe the structural changes of the micro-components under the condition of an applied electric field in real time, directly correspond the electrical properties of the micro-units to the microstructure, and reveal nanowires or nanowires at the atomic level. Electrical properties and conduction mechanisms of microdevices.

[0019] This embodiment is an electrical measurement platform for micro devices. The electrical measurement platform includes a supporting part and a circuit part. The supporting portion is an insulating substrate 1 . The circuit part is two opposite metal electrodes 2 and the components to be measured 3, 4 and the phase change material film 5 between them. The metal electrode is bonded to the insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com