Automobile air conditioner parallel flow evaporator

An automotive air-conditioning, parallel flow technology, applied in evaporator/condenser, space heating and ventilation details, household heating, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

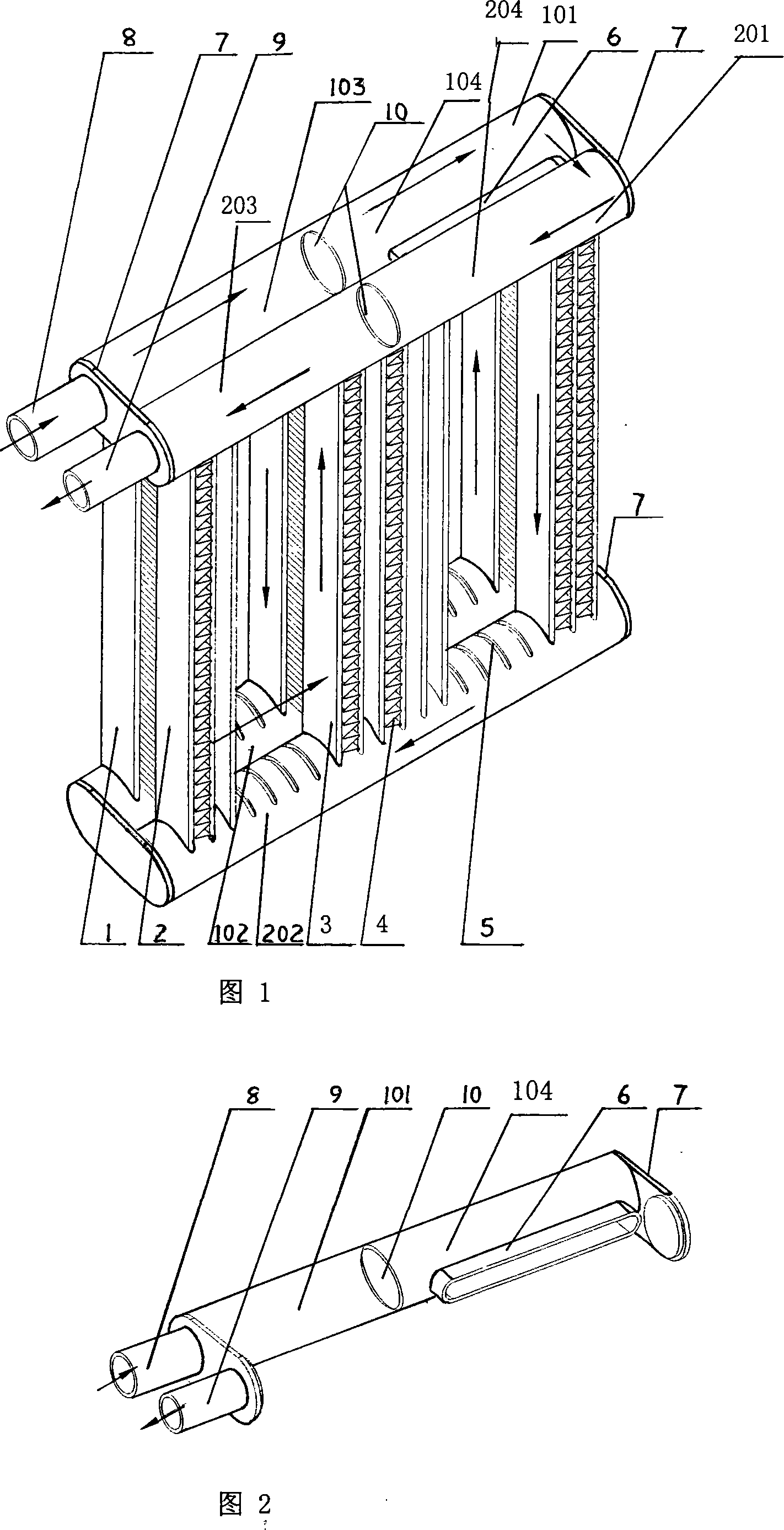

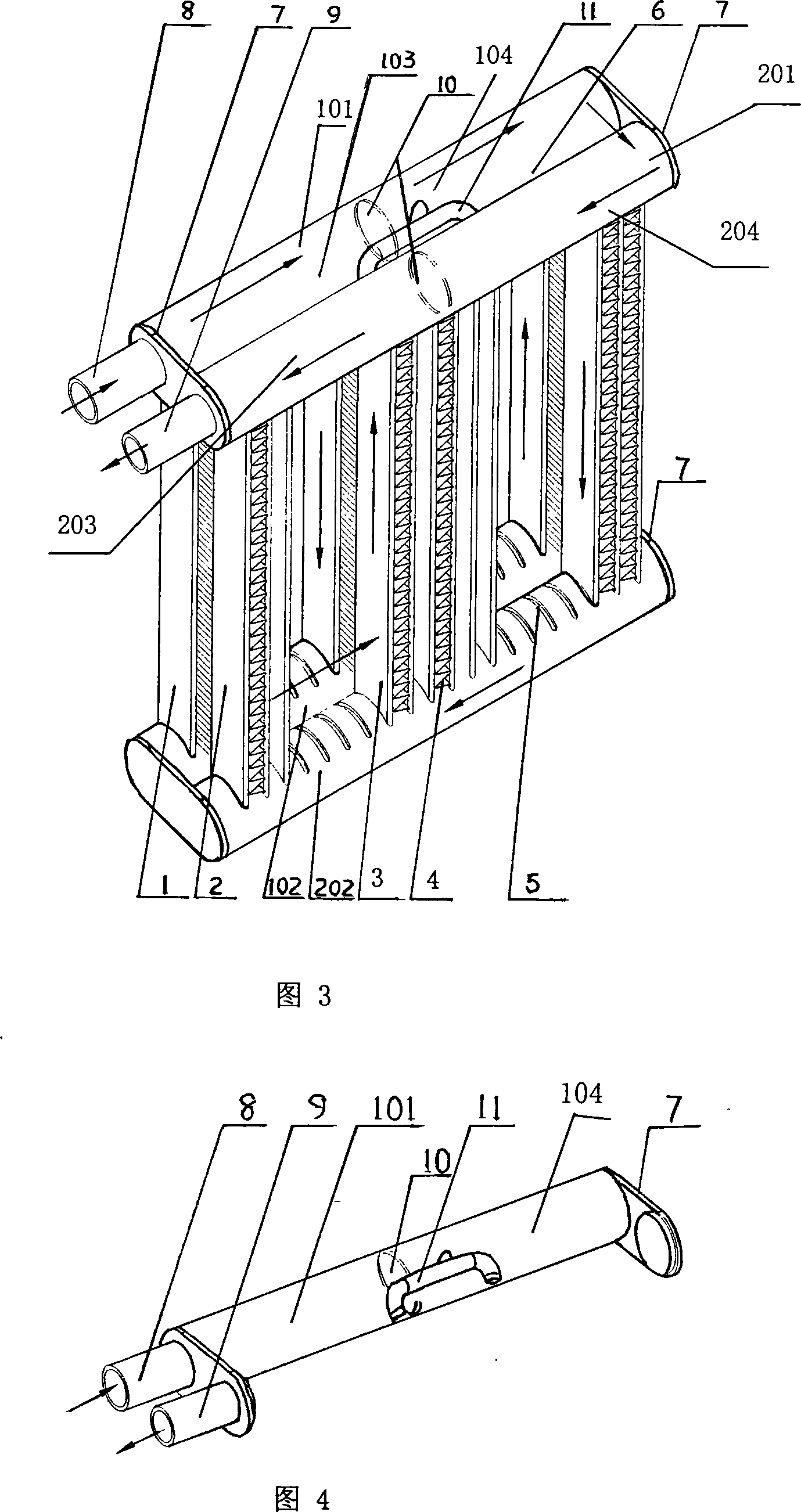

[0028] Please refer to the attached drawings to further describe the present invention.

[0029] As shown in Figures 1 and 2, the present invention provides a parallel flow evaporator for automobile air conditioners. The parallel flow evaporator includes two sets of heat exchange units arranged in parallel before and after each set of heat exchange units include porous flat tubes 3 and fins. Sheet 4, upper header 101 / 201, lower header 102 / 202, header cover 7, partition 10, inlet pipe 8 and outlet pipe 9, said upper header 101 / 201, lower header The outside of the tube wall of the flow tube 102 / 202 is provided with a number of mounting holes 5 for inserting the porous flat tube 3, and the porous flat tube 3 is respectively inserted into the upper header 201 and the lower header 202 of the front row heat exchange unit 2. In the mounting holes 5, the porous flat tubes 3 are respectively inserted into the corresponding mounting holes 5 of the upper header 101 and the lower header 102 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com