Method of preparing coupler yoke frame

A manufacturing method and hook tail frame technology, which is applied in the field of forging and forming, can solve the problems of high labor intensity, reduced bar material utilization rate, and low production efficiency, and achieve the goals of reducing labor intensity, saving heating steps, and reducing yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

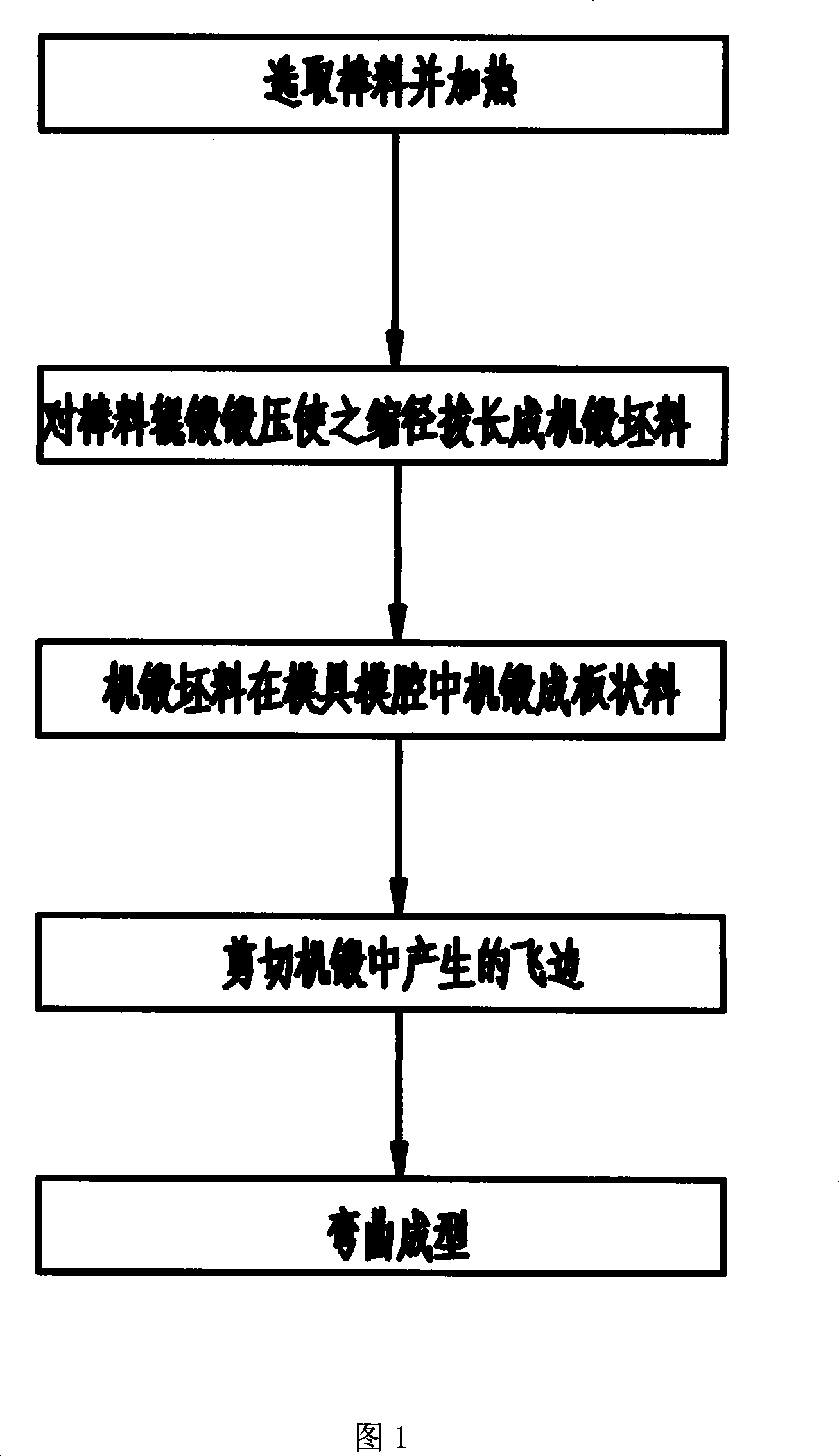

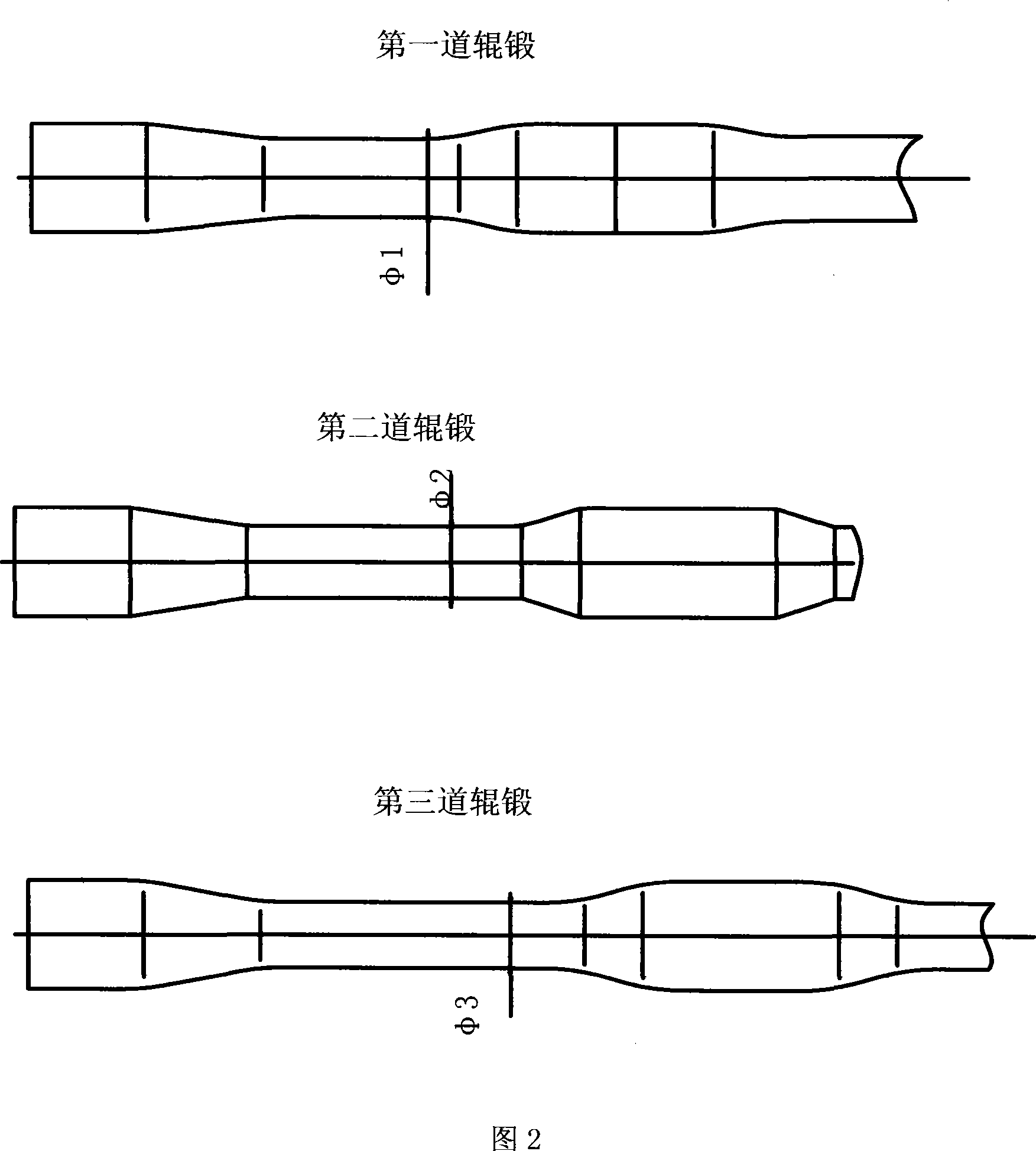

[0017] Below in conjunction with accompanying drawing Fig. 1, Fig. 2, the present invention is described in detail:

[0018] First select a 25MnCrNiMoA bar with a length of 1230mm and a diameter of 142mm, and then heat the bar to 1200-1250°C in a 1000KW intermediate frequency furnace; the preferred temperature is 1250°C, and then forge the heated bar to make it shrink in diameter and elongate To form a machine forged billet, the forging and drawing process adopts a roll forging machine for roll forging. The roll forging pressure of the roll forging machine is 300-700 tons. The bar is automatically clamped by a manipulator and sent to the roll forging machine for roll forging. The roll forging pressure is 400 tons; secondly, the machine forged blank is machine-forged into a plate-shaped material with a 6300T friction press in the mold cavity; the machine forged blank will produce flash during machine forging, so 1600T friction pressure is used immediately The size of the remain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com