Method for preparing TiC/TiB2 biphase ceramic granule partial reinforced manganese steel composite material

A technology of ceramic particles and local reinforcement, which is applied in the field of preparation of TiC and TiB2 dual-phase ceramic particles locally reinforced manganese-steel composite materials, which can solve the problems of reduced toughness and achieve the effects of inhibiting precipitation, good comprehensive performance, and reducing reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

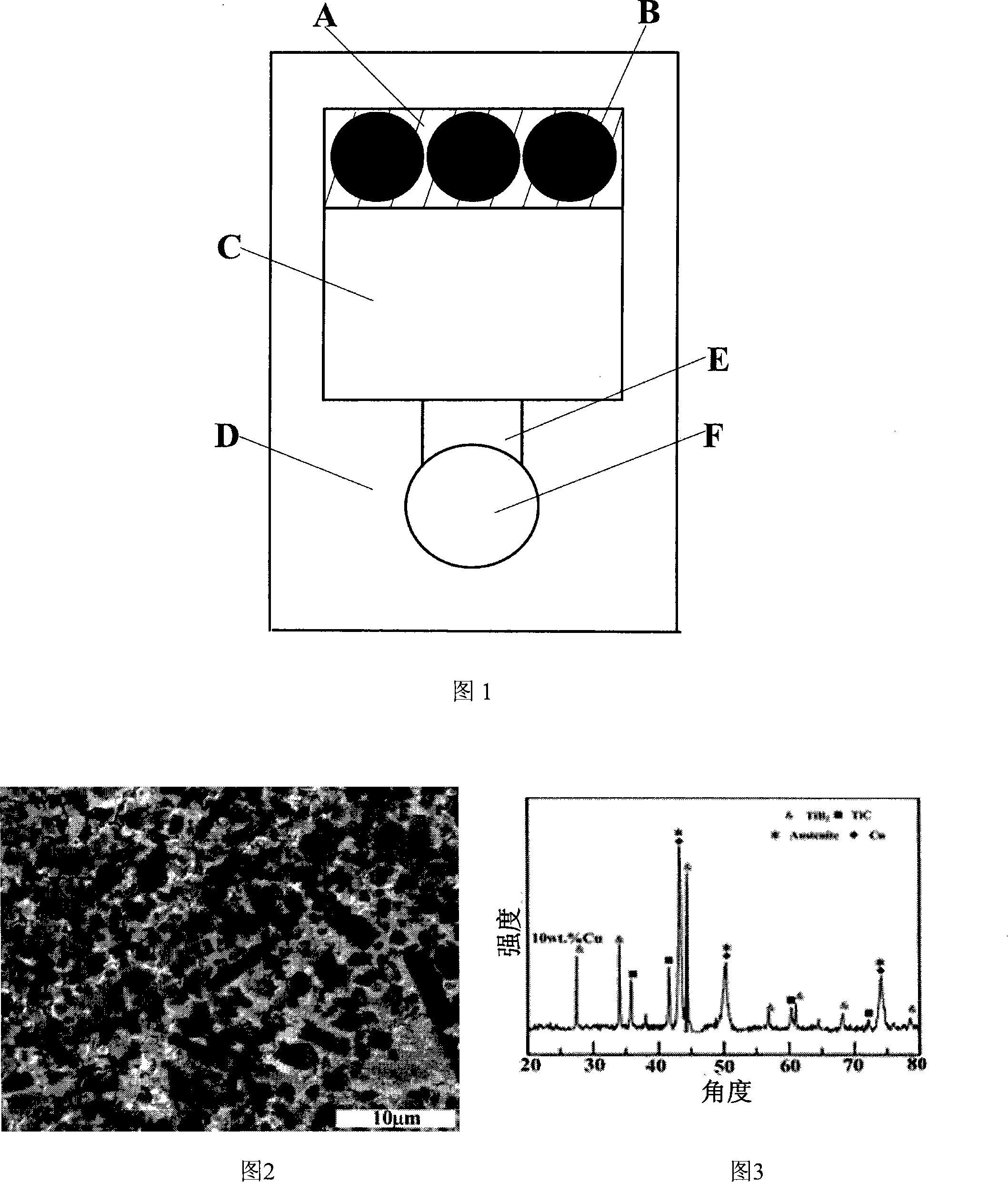

Method used

Image

Examples

Embodiment 1

[0029] 10wt.% Cu-Ti-B 4 TiC and TiB prepared by C system 2 Particle locally reinforced manganese-steel composites.

[0030] Cu powder (particle size less than 45 microns), Ti powder (particle size less than 38 microns) and B 4 C powder (particle size less than 3.5 microns) according to Ti and B 4 The molar ratio of C is Ti:B 4 C=3:1, the proportion of Cu content is 10wt.%, put the prepared powder into the low-speed mixer, mix for 6 hours, and press it into a cylindrical reaction prefabrication of Ф22×10mm at room temperature block, the compactness rate of the prefabricated block is 75±5%; the pressed Cu-Ti-B 4 C prefabricated block is placed in a low vacuum heating device, heated to 200°C at a heating rate of 15°C / min, and vacuum degassed for 2 hours; the reaction prefabricated block is taken out and placed in the mold where the casting needs to be strengthened. The matrix is manganese steel (mass percentage of chemical composition: C, 0.5 ~ 1.5, Mn, 5.0 ~ 25.0, Si 2 Th...

Embodiment 2

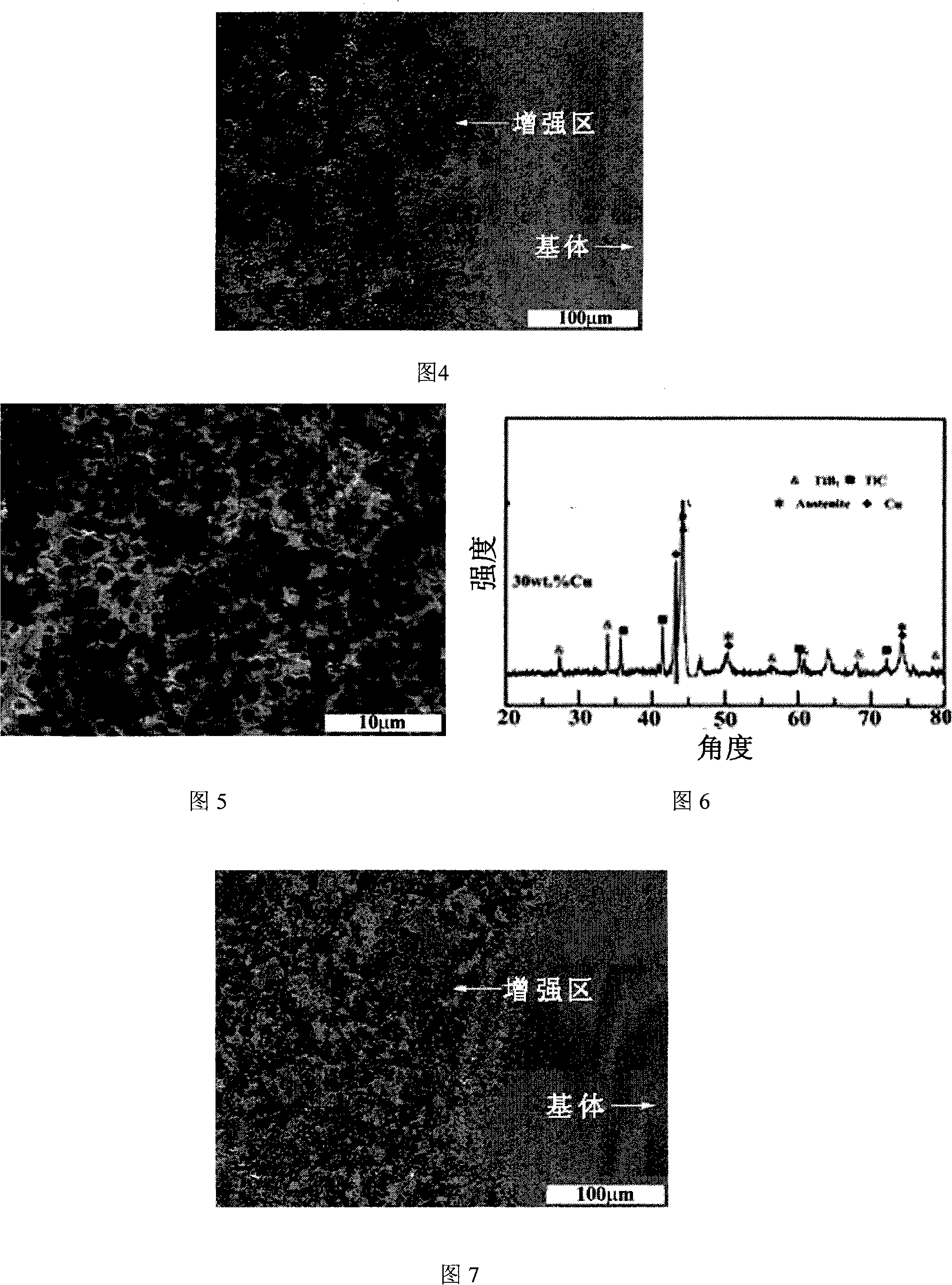

[0034] 30wt.% Cu-Ti-B 4 TiC and TiB prepared by C system 2 Particle locally reinforced manganese-steel composites.

[0035] Cu powder (particle size less than 45 microns), Ti powder (particle size less than 28 microns) and B 4 C powder (particle size less than 3.5 microns) according to Ti and B4 The molar ratio of C is Ti:B 4 C=3:1, the proportion of Cu content is 30wt.%, put the prepared powder into the low-speed mixer, mix for 7 hours, and press it into a cylindrical reaction prefabrication of Ф22×10mm at room temperature block, the compactness rate of the prefabricated block is 75±5%; the pressed Cu-Ti-B 4 C prefabricated block is placed in a low vacuum heating device, heated to 300°C at a heating rate of 25°C / min, and vacuum degassed for 3 hours; the reaction prefabricated block is taken out and placed in the casting mold where the casting needs to be strengthened. The matrix is manganese steel (mass percentage of chemical composition: C, 0.6~1.4, Mn, 6.0~20.0, Si2 T...

Embodiment 3

[0037] 60wt.% Cu-Ti-B 4 TiC and TiB prepared by C system 2 Particle locally reinforced manganese-steel composites.

[0038] Cu powder (particle size less than 45 microns), Ti powder (particle size less than 25 microns) and B 4 C powder (particle size less than 45 microns) according to Ti and B 4 The molar ratio of C is Ti:B 4 C=3:1, the proportion of Cu content is 60wt.%, put the prepared powder into the low-speed mixer, mix for 8 hours, and press it into a cylindrical reaction prefabrication of Ф22×10mm at room temperature block, the compactness rate of the prefabricated block is 75±5%; the pressed Cu-Ti-B 4 C prefabricated block is placed in a low vacuum heating device, heated to 400°C at a heating rate of 35°C / min, and vacuum degassed for 4 hours; the reaction prefabricated block is taken out and placed in the casting mold where the casting needs to be strengthened. The matrix is manganese steel (mass percentage of chemical composition: C, 0.7~1.3, Mn, 7.0~13.0, Si2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com