Semiconductor technology

A semiconductor and process technology, applied in the field of metal material hard mask technology, can solve the problems of substrate particle precipitation and process defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

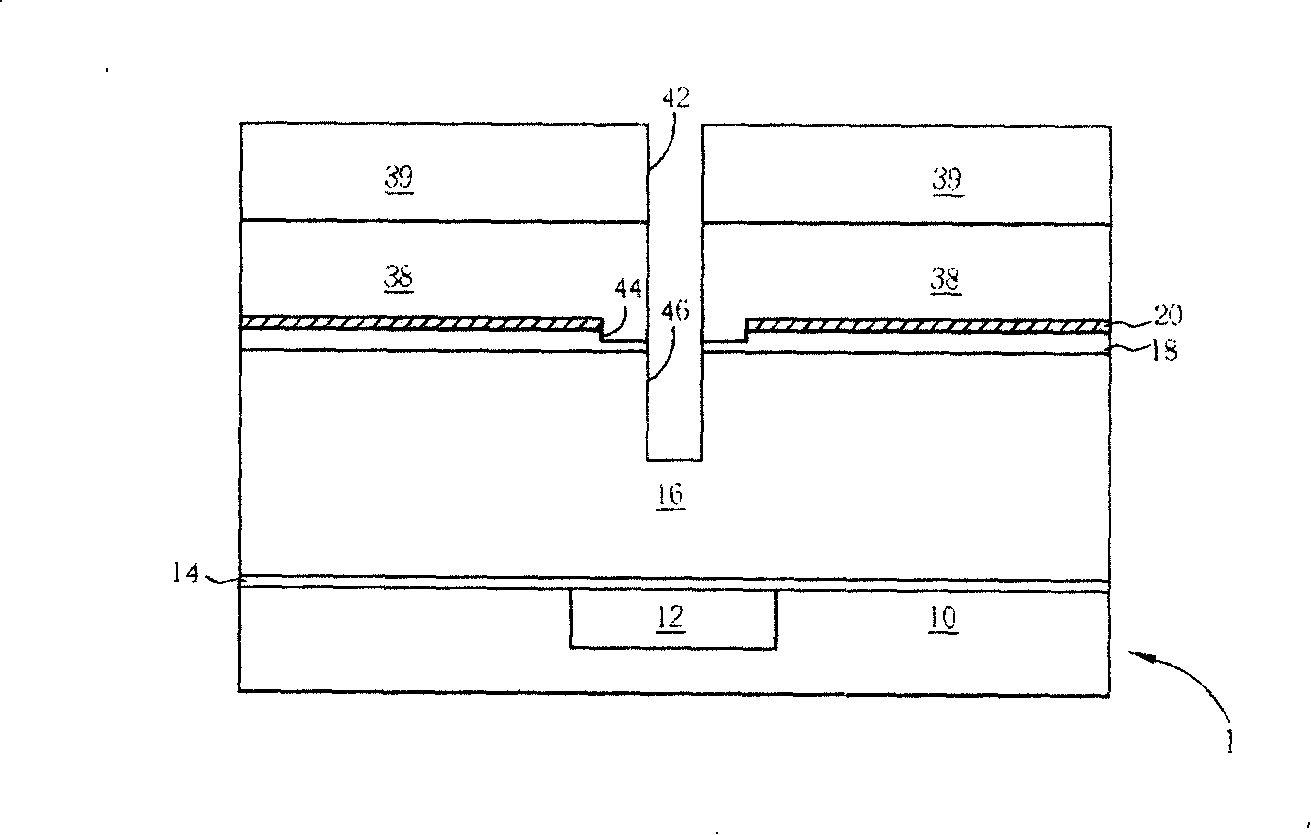

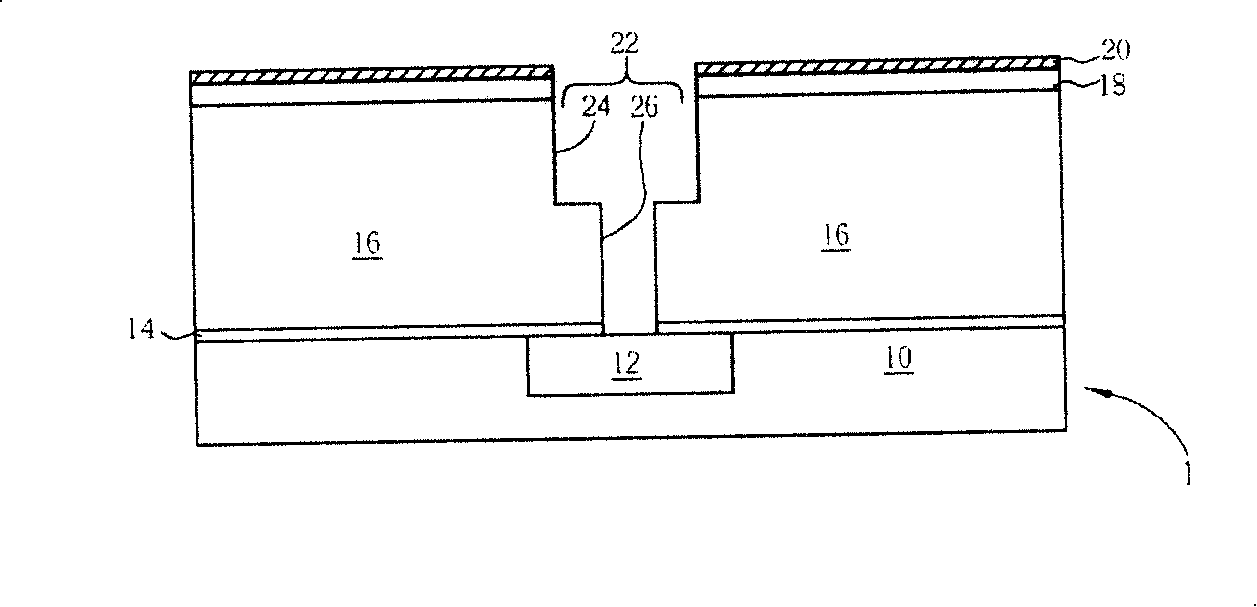

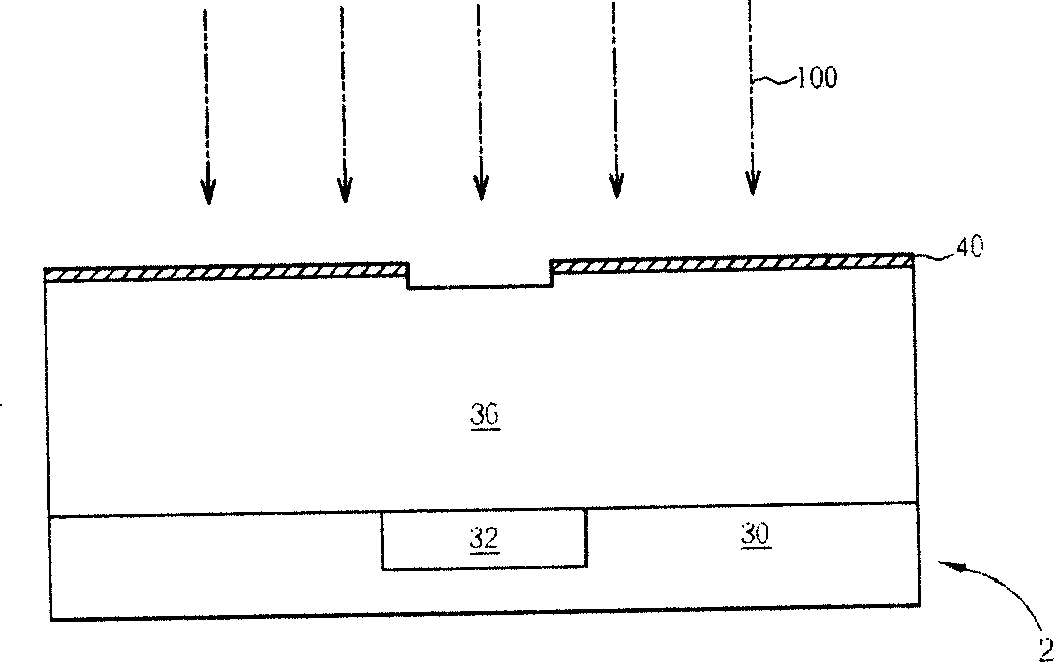

[0030] see image 3 and Figure 4 , which shows a schematic cross-sectional view of a specific embodiment of the semiconductor process according to the present invention, which uses a damascene process for illustration. The same symbols are still used to represent the same or similar elements or regions. It should be emphasized that the present invention is not limited to those disclosed in the figures, any hard mask, especially a hard mask containing titanium (Ti) components, such as titanium metal or titanium nitride, and the use of fluorine-containing radical gas Etching processes, such as, but not limited to, several damascene or dual damascene processes, can use the method of the present invention. The dual damascene process can be, for example, trench-first, via-first, partial via-first and other damascene processes.

[0031] Such as image 3 As shown, the substrate 2 may be a semiconductor substrate including an underlying or dielectric layer 30 . Formed in the die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com