Suction plastic packing machine

A plastic bag and body technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of long distance between the vacuum solenoid valve and the mold, low molding efficiency, poor bite force, etc., to reduce failure and maintenance time, improve Efficiency, quality, and downtime reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

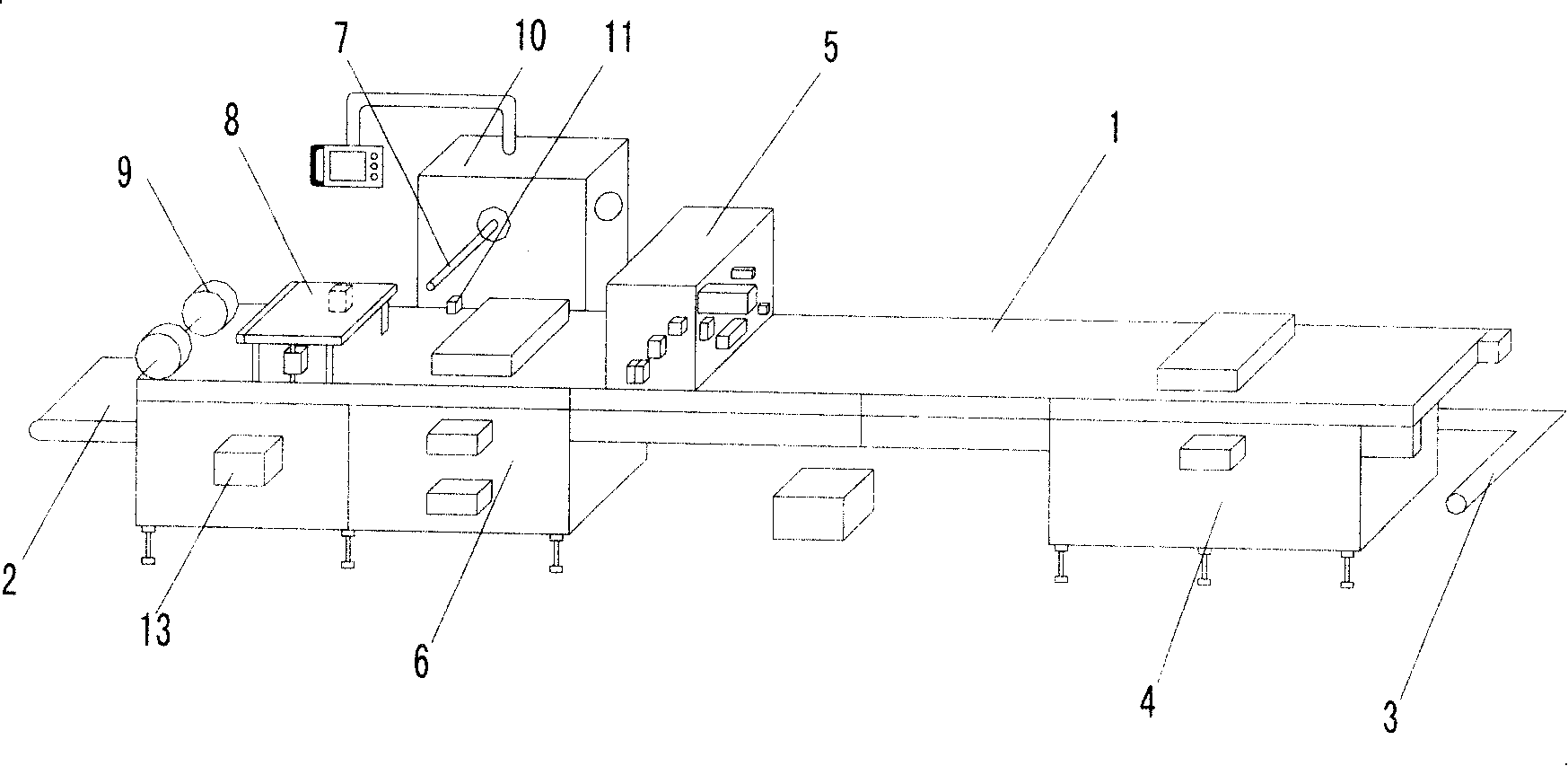

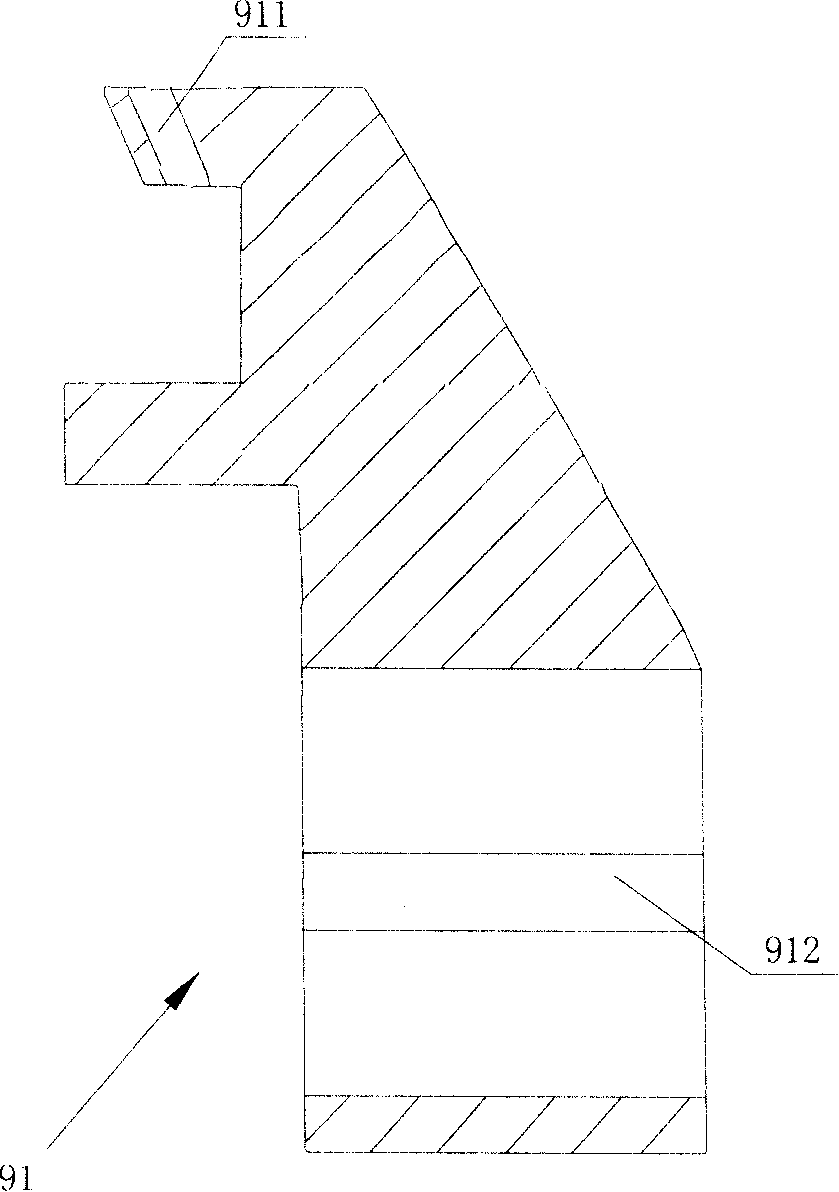

[0033] see figure 1 , The blister packaging machine involved in the present invention includes a body 1, a conveyor belt 2, a film unwinding mechanism 3, a blister mechanism 4, a printing mechanism 5, a heat sealing mechanism 6, a paper unwinding mechanism 7, a transverse cutting mechanism 8, a longitudinal cutting mechanism Mechanism and winding mechanism 9 and the electrical box 10, color code detection mechanism 11 and temperature control mechanism 12 that are arranged in cooperation. Conveyor belt 2 is driven by servo motor 13, and plastic-absorbing mechanism 4 and heat-sealing mechanism 6 respectively comprise an upper mold, a lower mold and a cylinder connected with the lower mold, and electric heating tubes are installed in the upper mold.

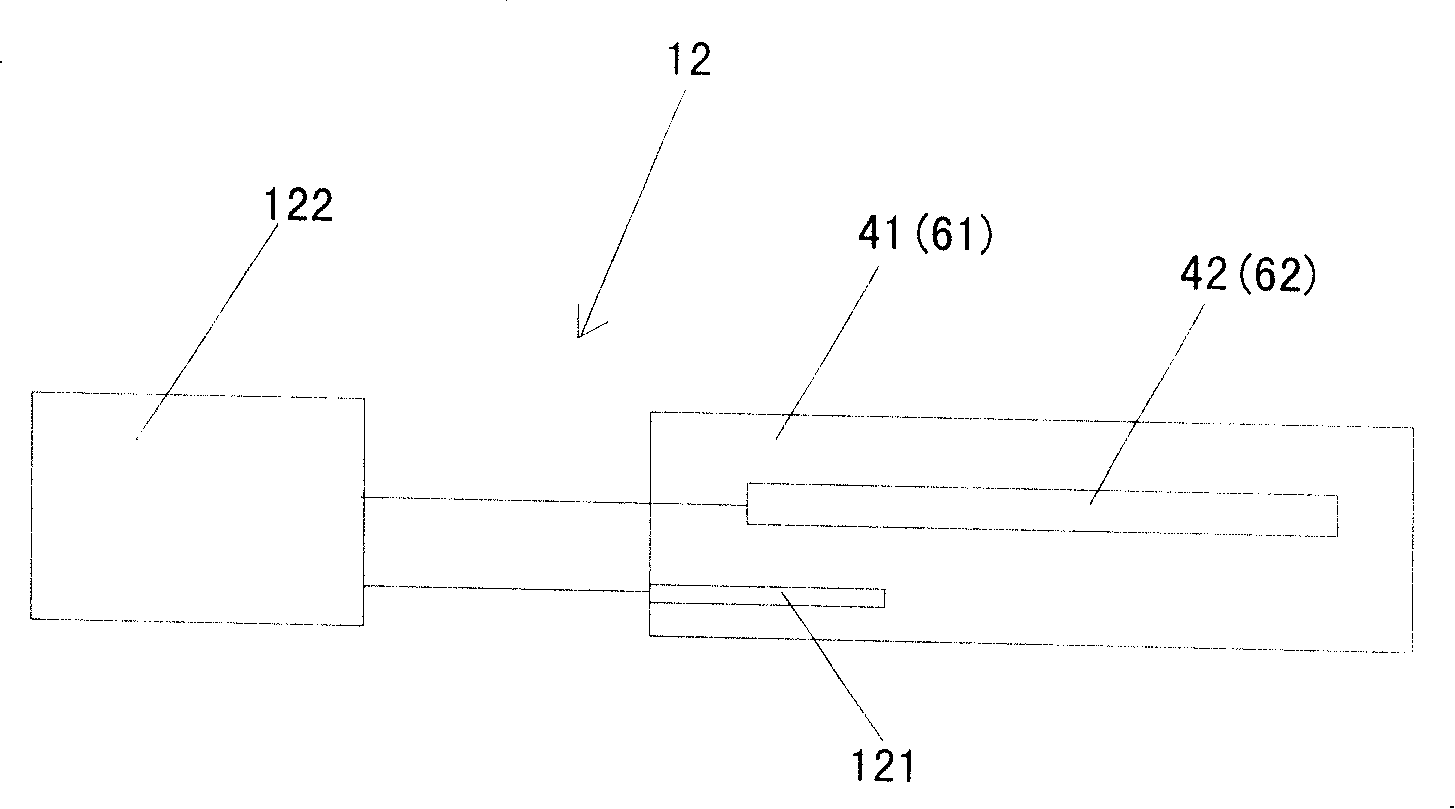

[0034] see figure 2 The temperature control mechanism 12 of the blister packaging machine of the present invention includes a temperature control mechanism for controlling the heating temperature of the blister mechanism and a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com