Preparation method of handicraft type salt and mold for press forming the same

A production method and compression molding technology, which can be used in food preparation, application, decorative art, etc., can solve the problems of no pressing molds, etc., and achieve the effects of facilitating processing, improving the economic benefits of enterprises, and producing methods that are safe, energy-saving and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

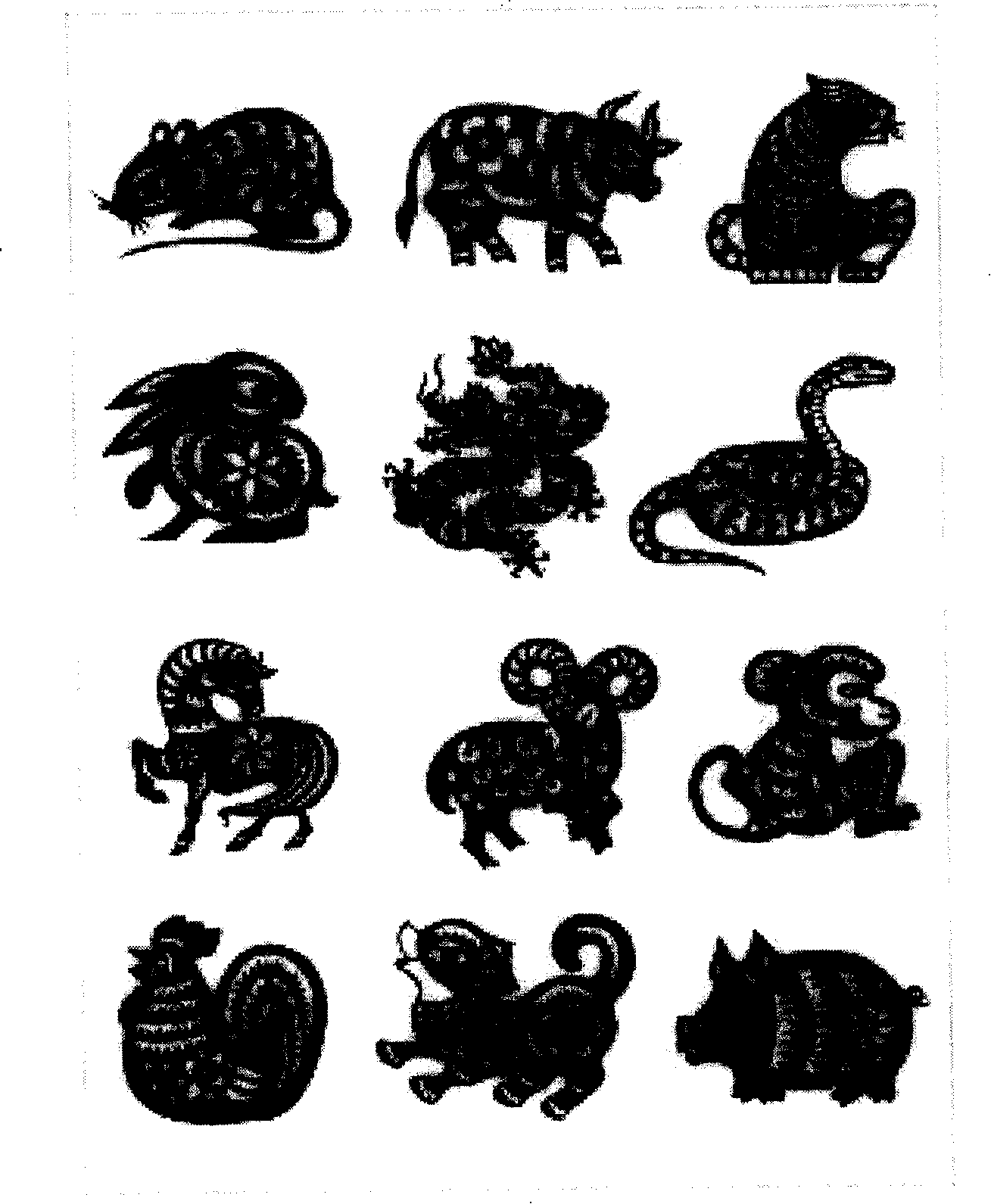

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of preparation method of handicraft type salt is characterized in that it is made of following steps:

[0034] ① Preparation of raw materials: select coarse-grain refined salt and fine-grain refined salt, and mix them evenly at a mass ratio of 8:2;

[0035] ②Dry the mixture of refined salt prepared in step ① so that the water content is 0.22%, put it into the mold, 2 Hold the pressure for 2min under the pressure and carry out the compression molding treatment.

[0036] 3. The refined salt pressed and formed in step 2. is demoulded;

[0037] ④ After routine product inspection and packaging, it is a finished product.

[0038] The coarse refined salt described in the above-mentioned steps 1. is the salt grain that average particle diameter is 0.2mm, and said fine granular refined salt average particle diameter is the salt grain of 0.075mm.

[0039] The compacted density of the refined salt after the compression molding described in above-mentioned s...

Embodiment 2

[0050] Embodiment 2: a kind of preparation method of handicraft type salt is characterized in that it is made of following steps: ④

[0051] ① Preparation of raw materials: select coarse-grain refined salt and fine-grain refined salt, and mix them evenly at a mass ratio of 8:2;

[0052] ②Dry the mixture of refined salt prepared in step ① so that the water content is 0.21%, put it into the mold, 2 Hold the pressure for 2min under the pressure and carry out the compression molding treatment.

[0053] 3. The refined salt pressed and formed in step 2. is demoulded;

[0054] ④ After routine product inspection and packaging, it is a finished product.

[0055] The coarse refined salt described in the above-mentioned steps 1. is the salt grain that average particle diameter is 0.2mm, and said fine granular refined salt average particle diameter is the salt grain of 0.075mm.

[0056]The mixture of coarse-grained refined salt and fine-grained refined salt described in above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Texture depth | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com