Infrared waveband ultra-material based on dendritic structure

An infrared band, dendritic technology, applied in the field of flat sandwich type metamaterials, can solve problems such as the difficulty of the split resonator ring structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] 1. Preparation of electrolyte: The preparation of copper dendritic structure uses a mixed solution of copper sulfate and sulfuric acid, and weighs different masses of CuSO 4 ·5H 2 O and concentrated H 2 SO 4 Dissolve in a certain amount of water, fully stir to dissolve, and get a blue transparent solution for use; the preparation of the silver particle film adopts the mixed solution of silver nitrate and polyethylene glycol-400 (PEG-400), and weigh different amounts of 1.18mMAgNO 3 and PEG-400:H 2 O=1:9 (v / v) was dissolved in a certain amount of water, stirred thoroughly to dissolve, and a colorless transparent solution was obtained for use.

[0012] 2. Preparation of electrodes: in the preparation process of copper dendritic structure, the anode is a traditional ring-shaped copper electrode. According to the size of the inner diameter of the petri dish used in the experiment, ring-shaped copper electrodes with different diameters are used, and the cathode adopts a ...

Embodiment 1

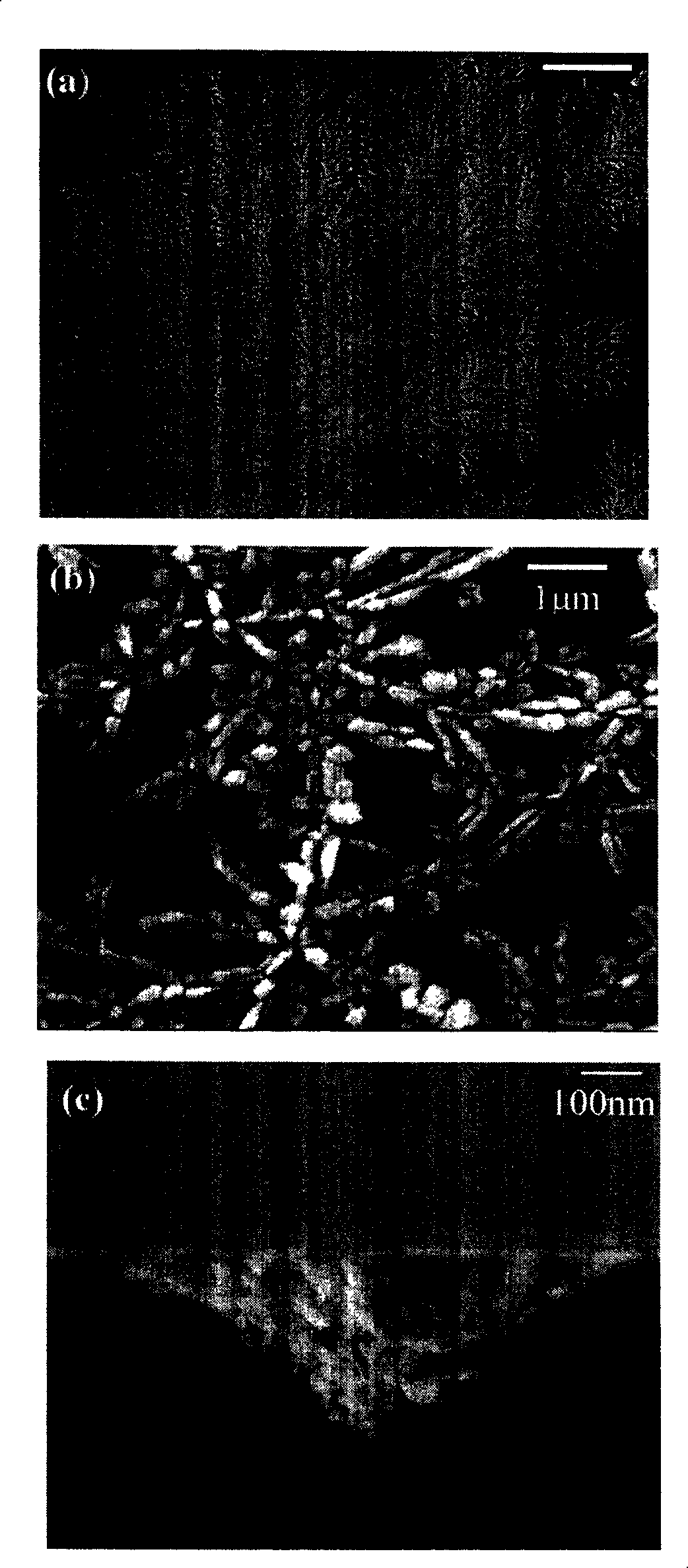

[0016] Example 1: The electrolyte used is 0.1M CuSO 4 ·5H 2 O and 1.0M H 2 SO 4 Add the electrolyte solution to the electrolytic cell, so that the amount of the added electrolyte solution is limited to just cover the cover glass placed in the electrolytic cell, the anode is a ring-shaped copper electrode, and the cathode is a carbon fiber electrode. Adjust the voltage of the DC stabilized power supply to 10V, turn on the loop to start electrodeposition, and the current in the loop is about 1.0mA. The electrodeposition time was controlled for 2 hours to obtain a copper dendritic structure material with an effective size of 4.0 mm. Optical micrographs and scanning electron micrographs of the samples are attached figure 1 shown. The infrared transmission spectrum measurement of the sample is carried out on the FT / IR-470Plus Fourier transform infrared spectrometer (the spot diameter is 4.0mm), and the measurement results are shown in the attached figure 2 a.

Embodiment 2

[0017] Embodiment two: the electrolyte used is 1.18mMAgNO 3 and PEG-400:H 2 A mixed solution of O=1:9 (v / v), the electrolyte is added to the electrolytic cell, and the metal silver sheet anode and the cut ITO conductive glass are inserted into the electrode pool, so that the conductive surface of the ITO conductive glass and the metallic silver The slices are strictly corresponding, and the distance between them is kept at about 5.0cm. The entire electrodeposition system is placed in an ice-water bath, so as to keep the temperature of the electrolyte in the electrolytic cell not higher than 5°C during the entire electrodeposition process, and use a magnetic stirrer to evenly stir the electrolyte during the entire electrodeposition process. Adjust the voltage of the DC stabilized power supply to 1.5V, connect the loop to start electrodeposition, and the current in the loop is about 0.6mA. The time of electrodeposition is controlled at about 30 minutes, and the thin film of me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com