Large volume sample injection method and special chip in micro-current-control chip

A microfluidic chip, large-volume sample injection technology, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of high channel size requirements on the microfluidic chip, poor separation effect, and difficulty in automation. Create fast, easy to automate, and achieve automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

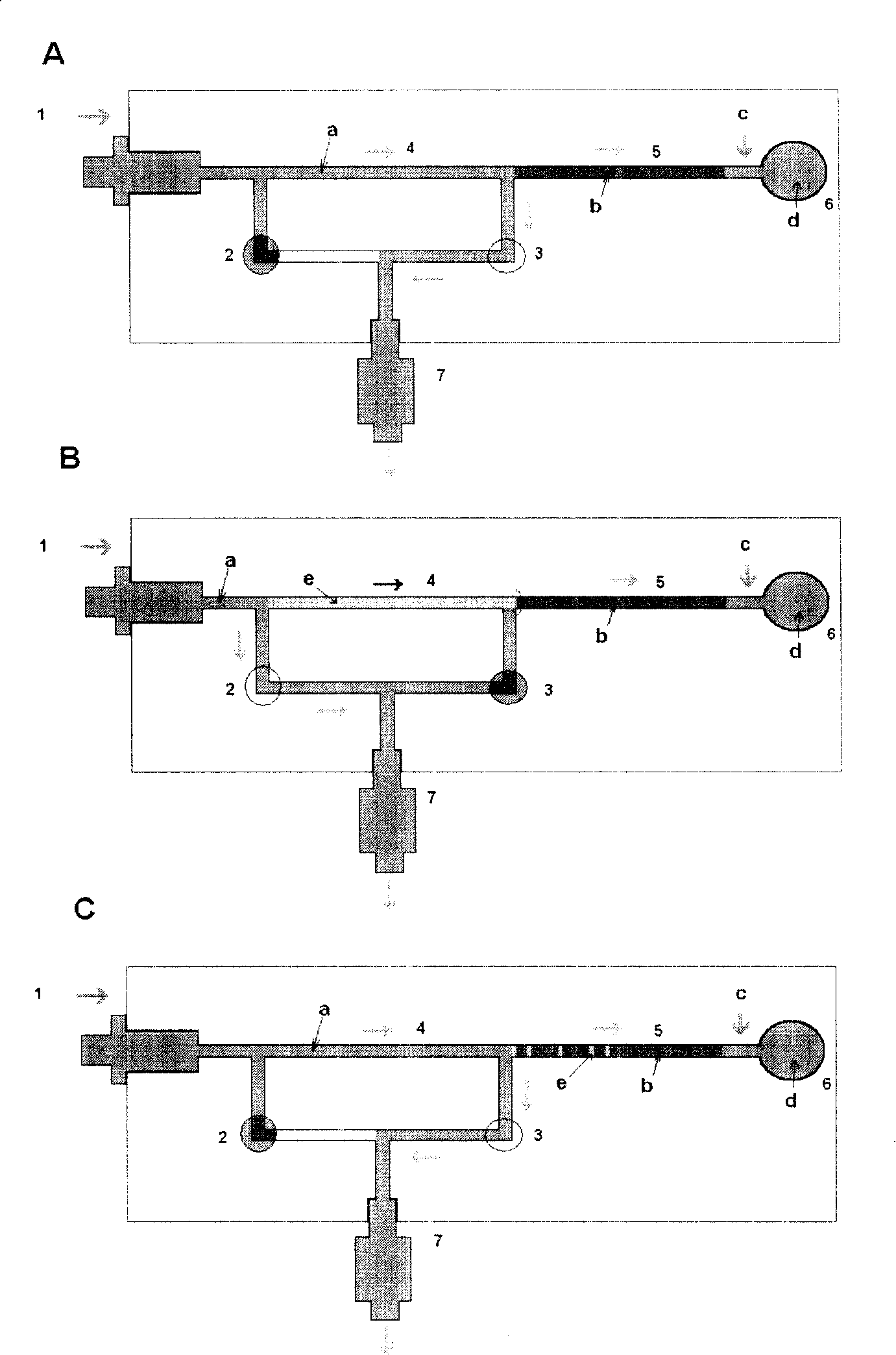

[0021] see figure 1 , the present invention provides a device for large-volume sampling in a microfluidic chip, which consists of a pump interface 1, a flow controller 2, a flow controller 3, a sampling channel 4, a separation channel (including stationary phase b) 5, The waste liquid tank 6 and the pressure controller 7 are composed. Sample e can be separated by pressure-driven or electric-driven, in which flow path controllers 2 and 3 are temperature flow path cut-off controllers.

[0022] When equilibrating the stationary phase b in the separation channel, as figure 1 -A, close the flow controller 2, and open the flow controller 3. The mobile phase a passes through the injection channel 4 at a high flow rate, and is split before the separation channel 5 . The pressure in the device is controlled by a pressure controller 7 .

[0023] During sample injection, such as figure 1 -B, sample e can be introduced into the flow path by the injection valve, and then transported i...

Embodiment 2

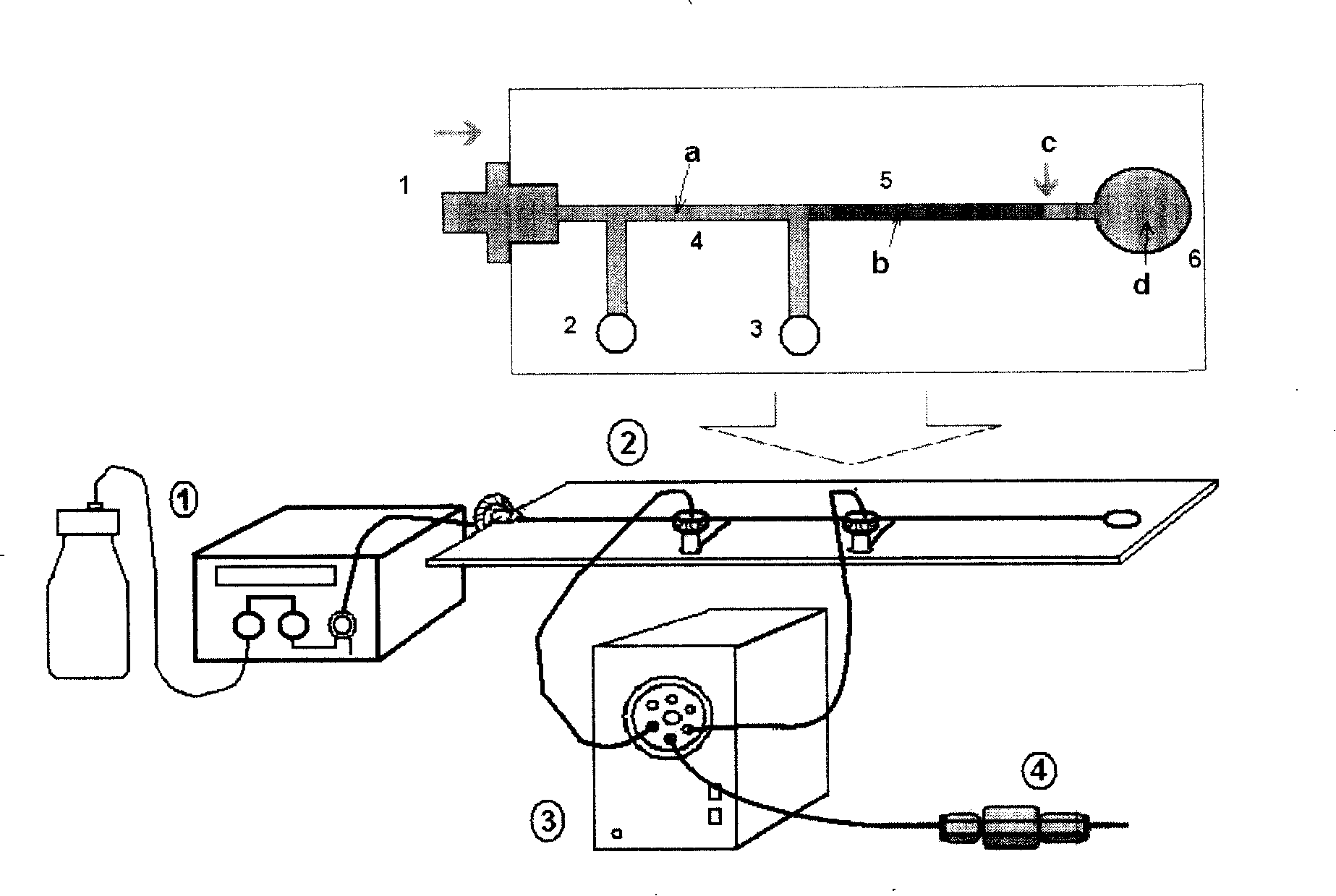

[0026] Such as figure 2 As shown, the microfluidic chip uses an external flow switching system to switch the flow path, and the purpose of large-volume sample injection can still be achieved. Among them, ① is a pump and a sampling device; ② is a microfluidic chip; ③ is a switching device; ④ is a pressure control device. The microfluidic chip includes an interface 1 with the pump, interfaces 2 and 3 connected with an external flow switching system, a sampling channel 4 , a separation channel (including stationary phase b) 5 and a waste liquid tank 6 .

[0027] When balancing the stationary phase b in the separation channel, the flow path 2 is closed and the flow path 3 is opened through an external flow path switching system. The mobile phase a passes through the injection channel 4 at a high flow rate, and is split before the separation channel 5 . The pressure in the device is controlled by an external pressure controller d.

[0028] When the sample is injected, the sampl...

Embodiment 3

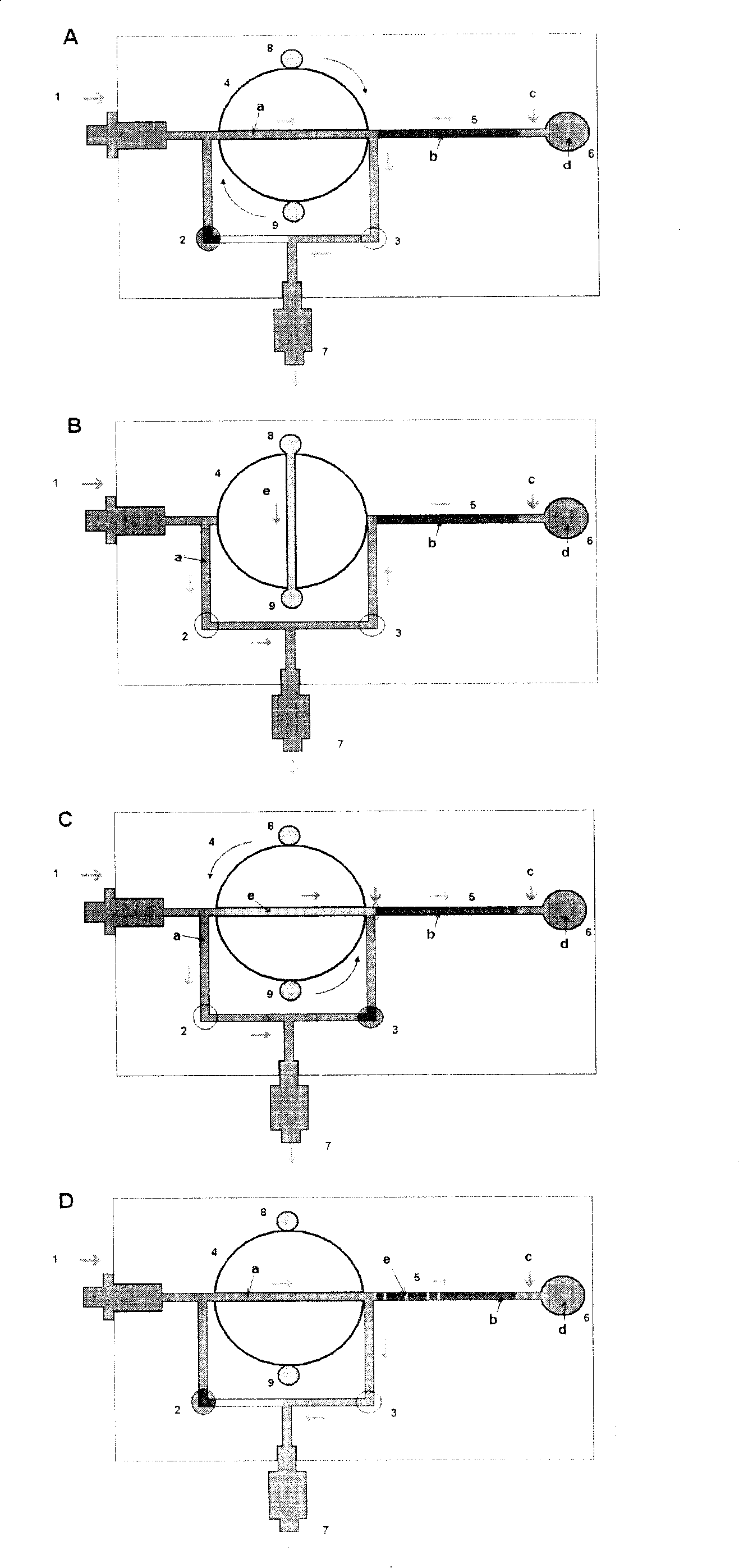

[0031] Such as image 3 As shown, the present invention provides a microfluidic chip large-volume sampling device with a rotary sampling valve, consisting of a pump interface 1, a flow controller 2, a flow controller 3, a rotary sampling valve 4, and a separation channel ( It consists of stationary phase b) 5, waste liquid tank 6, pressure controller 7, sample injection tank 8 and sample waste liquid tank 9. The sample can be introduced into the microfluidic chip by pressure or electric drive, and the sample can be separated by pressure drive or electric drive. Wherein the flow path controller is a temperature flow path cut-off controller.

[0032] When equilibrating the stationary phase b in the separation channel, as image 3 -A, close the flow controller 2, and open the flow controller 3. The mobile phase a passes through the sample channel of the rotary sampling valve 4 at a high flow rate, and is divided before the separation channel 5 . The pressure in the device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com