Method for extracting isoflavone from red clover

A technology of red clover and isoflavones, which is applied in the field of extracting isoflavones, can solve the problems of no benefit to human health, complex procedures, high cost, etc., and achieve the effects of reducing pollution, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

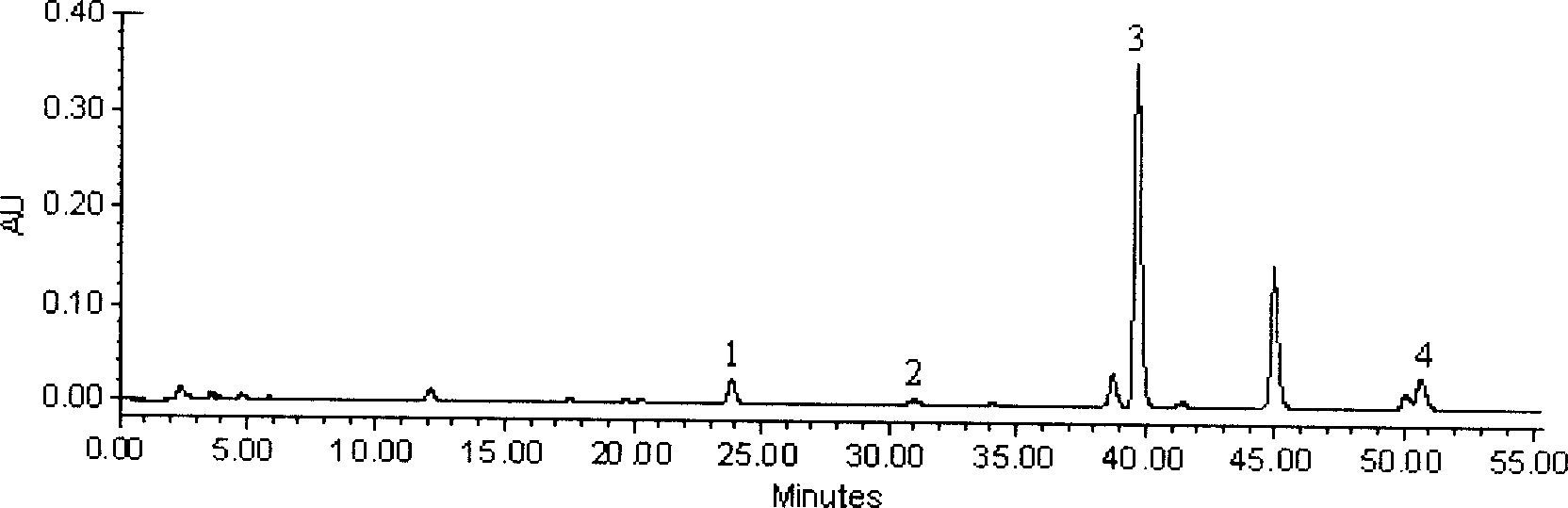

Image

Examples

Embodiment 1

[0026] Take the whole red clover, crush it, heat and reflux extract twice with 85% ethanol solution containing 1mol / L hydrochloric acid, each time for 1.5 hours, combine the extracts, filter, and use the filtrate for later use.

[0027] The above filtrate was recovered with ethanol, concentrated, adjusted to neutral pH with sodium hydroxide solution, centrifuged, dissolved in sodium hydroxide solution and adjusted to pH 10, centrifuged, and the supernatant was set aside.

[0028] The above supernatant was kept warm at 40°C, and then microfiltration, ultrafiltration and nanofiltration were performed sequentially in a roll-type membrane separation device with an operating pressure of 0.15 MPa. The microfiltration membrane is polyvinylidene fluoride membrane with a pore size of 0.45 μm, the ultrafiltration membrane is a polysulfone membrane with a molecular weight cut-off of 5000KD, and the nanofiltration membrane is a polyethersulfone membrane with a molecular weight cut-off of 2...

Embodiment 2

[0032] Take the whole red clover, grind it, heat and reflux extract twice with 65% ethanol solution containing 0.5mol / L hydrochloric acid, each time for 2 hours, combine the extracts, filter, and use the filtrate for later use.

[0033] The above filtrate was recovered with ethanol, concentrated, adjusted to neutral pH with sodium hydroxide solution, centrifuged, dissolved in sodium hydroxide solution and adjusted to pH 9, centrifuged, and the supernatant was set aside.

[0034] The above supernatant was kept warm at 30°C, and then microfiltration, ultrafiltration and nanofiltration were performed sequentially in a roll-type membrane separation device with an operating pressure of 0.10 MPa. The microfiltration membrane is polyvinylidene fluoride membrane with a pore size of 0.2 μm, the ultrafiltration membrane is a polyethersulfone membrane with a molecular weight cut-off of 1000KD, and the nanofiltration membrane is a polysulfone membrane with a molecular weight cut-off of 100...

Embodiment 3

[0038] Take the whole red clover, crush it, heat and reflux extract twice with 95% ethanol solution containing 0.1 mol / L hydrochloric acid, each time for 1 hour, combine the extracts, filter, and use the filtrate for later use.

[0039] The above filtrate was recovered with ethanol, concentrated, adjusted to neutral pH with sodium hydroxide solution, centrifuged, dissolved in sodium hydroxide solution and adjusted to pH 11, centrifuged, and the supernatant was set aside.

[0040]The above supernatant was kept warm at 25°C, and then microfiltration, ultrafiltration and nanofiltration were performed sequentially in a roll-type membrane separation device, with an operating pressure of 0.12MPa. The microfiltration membrane is polyvinylidene fluoride membrane with a pore size of 0.2 μm, the ultrafiltration membrane is polyethersulfone with a molecular weight cut-off of 50,000KD, and the nanofiltration membrane is polysulfone membrane with a molecular weight cut-off of 300KD.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com