Melt casting type diamond drill bit

A diamond drill bit and drill bit technology are applied in drill bits, drilling equipment, earth-moving drilling, etc., and can solve the problems of unsuitable drilling and cutting of granite materials and low melting point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

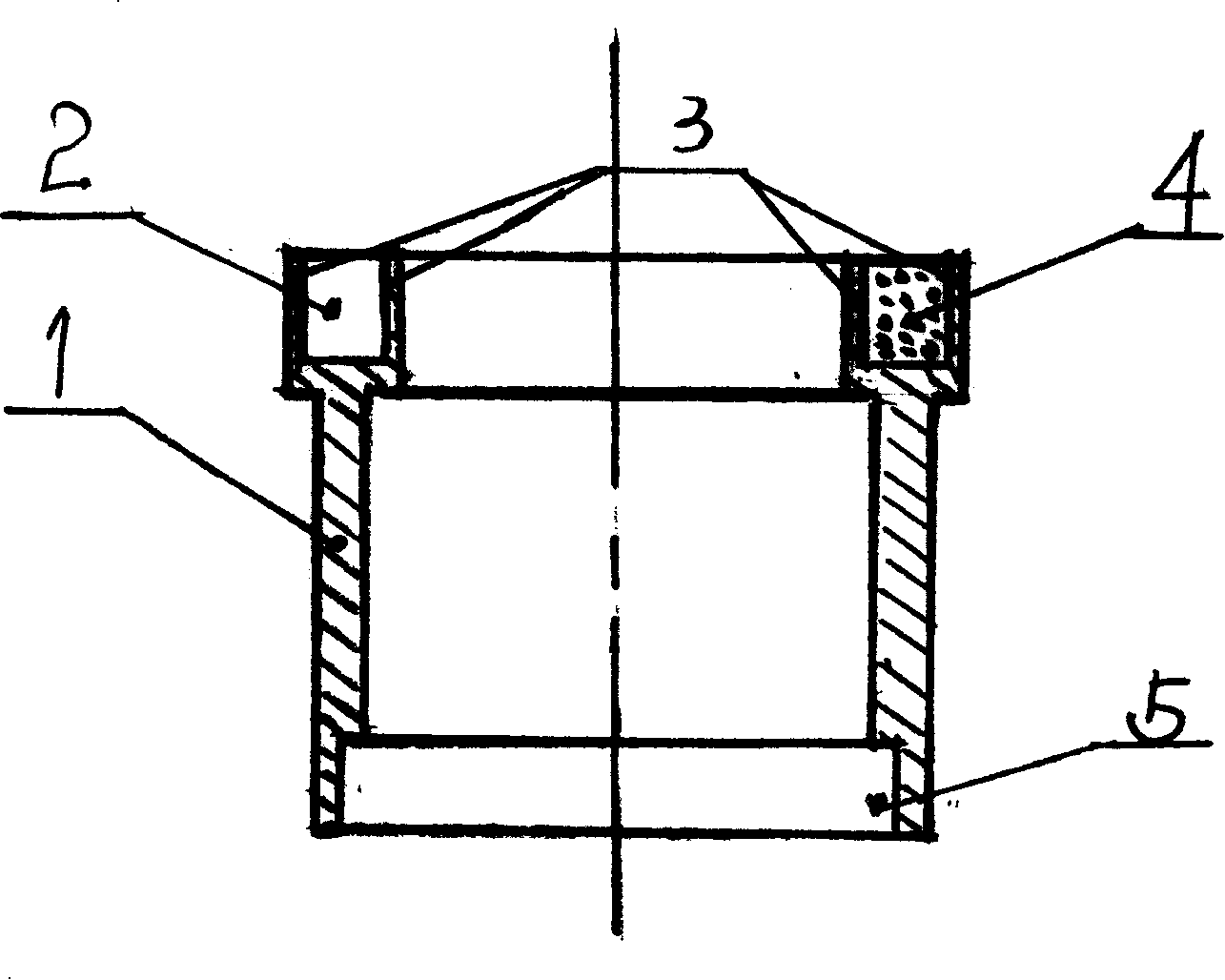

[0008] Such as figure 1 The fused-cast diamond drill bit shown is directly made a fused-cast trough (2) with a fused-cast trough frame (3) on the drill steel base (1), and puts prepared metal powder into the fused-cast trough (2) , the mixture (4) of silicon carbide and diamond particles is compacted and sent into a vacuum furnace or a gas-protected heating furnace. It is cast in a temperature range of 680°C-980°C for 5-8 minutes, and then it can be cooled naturally after being released from the furnace. After cooling, the casting frame (3) is removed by machining, and the drill pipe is welded on the matching port (5), so that the finished casting diamond drill bit is made.

[0009] According to the above-mentioned implementation technical scheme, diamond drill bits such as engineering thin-wall drills, geological drills, and deep well drills can be made. It saves energy and is sharper than the sintered type; it saves a lot of manufacturing time than the multi-layer electropl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com