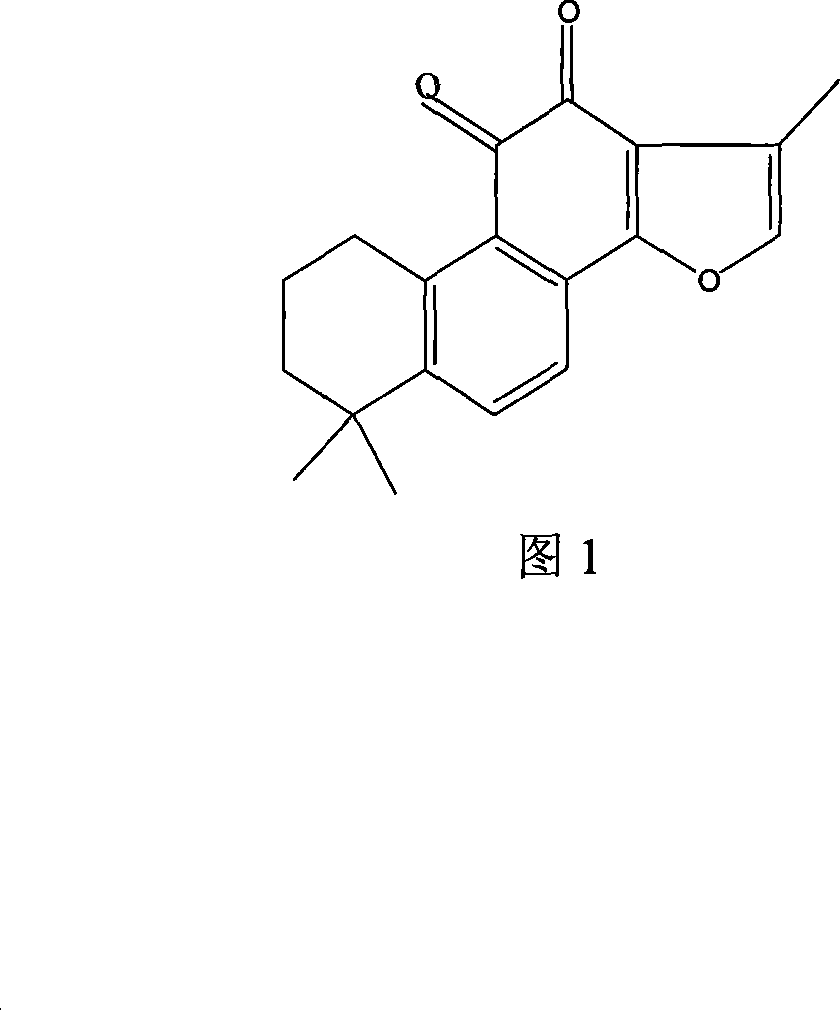

Method for preparing high-purity tanshinoneIIA

A tanshinone and high-purity technology is applied in the field of preparation of high-purity tanshinone IIA, which can solve problems such as harm to health, complicated operation, and excessively long process flow, so as to reduce the harm of operators, simplify operation procedures, and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

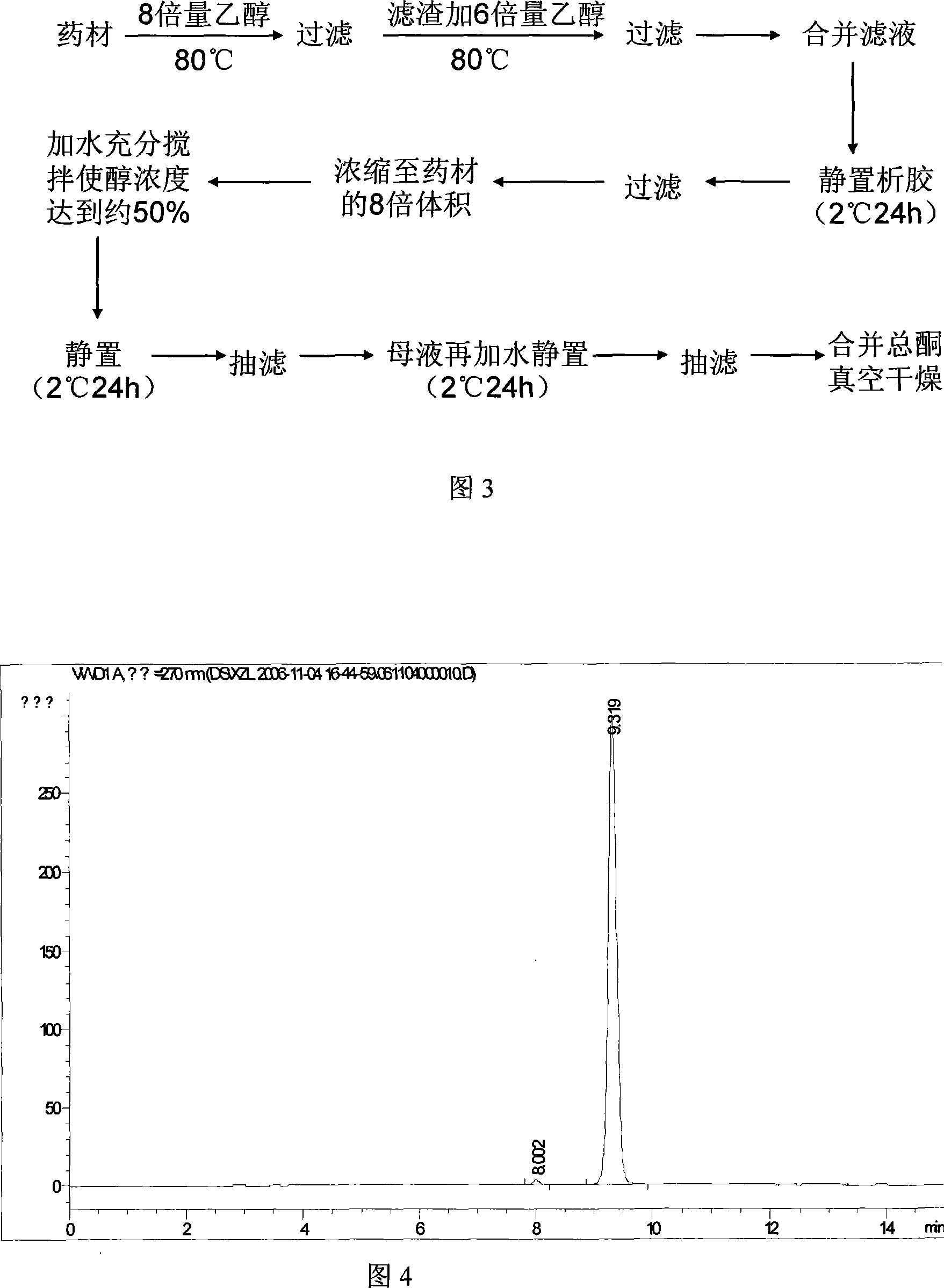

[0039] 1. Extraction of total ketones of salvia miltiorrhiza

[0040] Take 10 kg of Salvia miltiorrhiza (about 1 cm in diameter), add 8 times the amount of 95% ethanol for reflux extraction at 80°C for 2 hours, filter, add 6 times the amount of 95% ethanol for reflux extraction for 2 hours, filter, and combine the filtrates, statically at 2°C Set aside for 24 hours, analyze the gel, filter, concentrate to 8 times the volume of the medicinal materials, slowly add water and stir fully to make the alcohol concentration reach about 50%, stir thoroughly, then stand for 24 hours (2°C), and vacuum filter and dry to obtain the total ketone in vacuum. Add water to the mother liquor to precipitate, let stand for 24 hours (2° C.) and suction filter to dry the total ketones. The yield of total ketones is about 1.05%. The flowchart is shown in Figure 3.

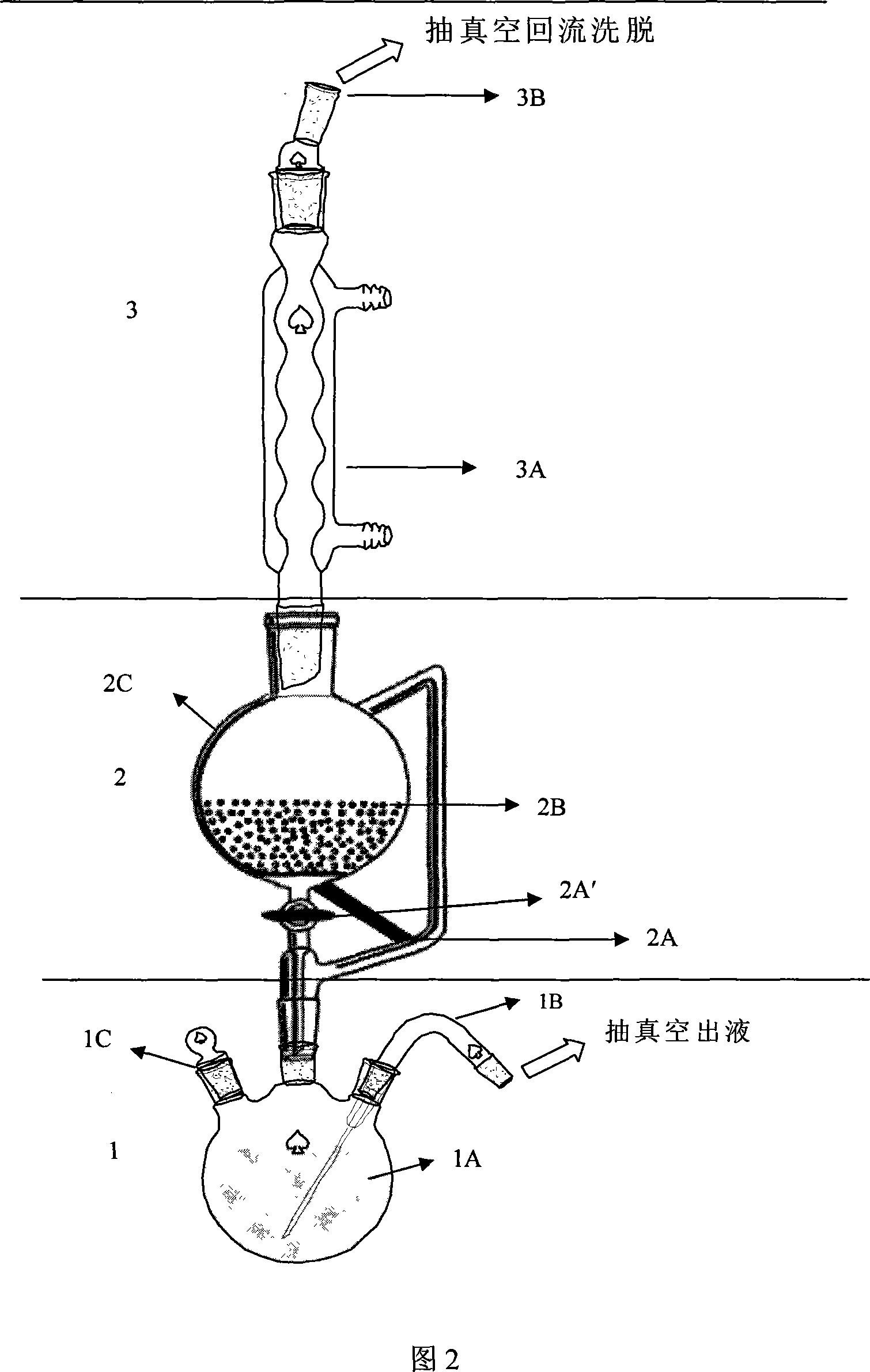

[0041] 2. Isolation of Tanshinone IIA

[0042] The total ketones obtained in the above process are weighed to obtain 105g total ketone...

Embodiment 2

[0044] 1. Extraction of total ketones of salvia miltiorrhiza

[0045] Take 20kg of salvia miltiorrhiza (about 1 cm in diameter), and operate the same process as in Example 1 to obtain 238 g of salvia miltiorrhiza ketones, with a yield of 1.19%.

[0046] 2. Isolation of Tanshinone IIA

[0047] 238g of total ketones obtained in the above process were loaded into the spherical chromatographic system with 5 times the amount of silica gel (wet loading of cyclohexane), and the total ketones and silica gel were mixed 1:1 before sample loading, and added to the bottom flask. An appropriate amount of cyclohexane and dichloromethane 98:2 (volume ratio) mixed solvent is heated to 50°C under vacuum to start eluting, so that the reflux velocity and the velocity of the liquid droplet are balanced, and the ratio of the solvent system is changed after extraction for 5 hours. Cyclohexane and methylene chloride were eluted at a ratio of 95:5, the eluate was concentrated, and recrystallized rep...

Embodiment 3

[0049] 1. Extraction of total ketones of salvia miltiorrhiza

[0050] Take 30kg of salvia miltiorrhiza (about 1 cm in diameter), and operate the same process as in Example 1 to obtain 366 g of salvia miltiorrhiza ketones, with a yield of 1.22%.

[0051] 2. Isolation of Tanshinone IIA

[0052] 366g of total ketones obtained in the above process were loaded into the pear-shaped chromatographic system with 6 times the amount of silica gel (cyclohexane wet loading), and the total ketones and silica gel were mixed 1: 1 before sample loading, and then placed in the bottom flask Add an appropriate amount of cyclohexane and dichloroethane 99:1 (volume ratio) mixed solvent, heat to 50°C under vacuum to start elution, so that the reflux speed and the speed of the droplets are balanced, and the ratio of the solvent system is changed after 5 hours of extraction , eluted with cyclohexane and dichloroethane 97:3, concentrated eluate, and repeated recrystallization with 95% ethanol to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com