High road service area sewage water treating process and dynamic membrane bioreactor

A bioreactor, sewage treatment technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of large area and poor resistance to water quality changes , ammonia nitrogen, phosphate can not meet the standard stably, to achieve the effect of ensuring stable discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

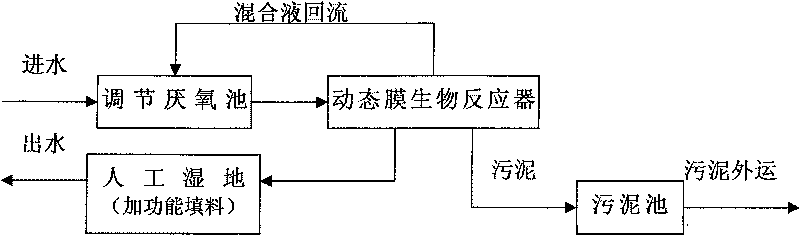

[0020] In the present invention, the sewage in the service area enters the dynamic membrane bioreactor after passing through the grid and adjusting the anaerobic tank, and then enters the artificial wetland for advanced treatment before being discharged.

[0021] The grille can adopt coarse grille or fine grille in ordinary grille or mechanical grille.

[0022] Adjust the anaerobic pool, which can be underground or semi-underground, with a volume of 0.8 to 1.0 times the daily sewage production in the service area. The adjustment anaerobic pool can be rectangular, with an aspect ratio of 2 to 5:1, and 0.2 to 0.5 of the effective volume of the adjusted anaerobic pool is the anaerobic zone. Stirring in the anaerobic zone can use submersible mechanical mixers, jet mixers or vertical mixers.

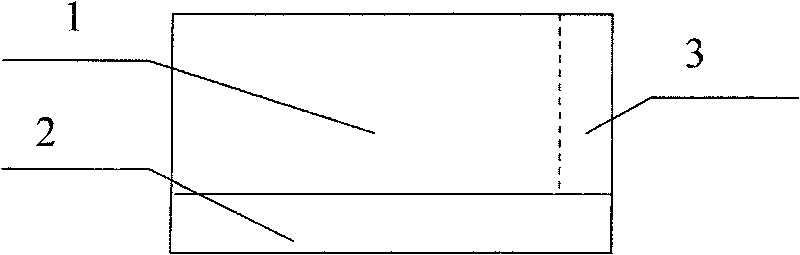

[0023] Sewage from the adjusted anaerobic tank is sent to the reaction zone of the dynamic membrane bioreactor with a submersible sewage pump or a sewage pump. The flow rate of the water pu...

Embodiment 2

[0027] Embodiment 2: Apply the present invention to transform the sewage treatment facilities in a certain expressway service area.

[0028] The sewage production volume in this service area is 150m 3 / d. The adjusted anaerobic pool used is 16.5m long, 5m wide, and the aspect ratio is 3.3:1. Adjust the effective volume of the anaerobic pool to 150m 3 , can adjust the amount of sewage in the service area for a day, and adjust the area of the anaerobic pool to 82m 2 . The effective volume of the anaerobic tank is 50m 3 , accounting for 0.33 of the total effective volume of the regulated anaerobic tank. A single dynamic membrane bioreactor is 6m long, 3m wide and 2m high, and the total effective volume of the dynamic membrane bioreactor is 64m 3 , The effective water depth of the dynamic membrane bioreactor is 1.8m, which is 300mm higher than the upper part of the dynamic membrane module. There are 320 pieces of dynamic membrane modules in the dynamic membrane bioreactor...

Embodiment 3

[0030]The sewage in the service area flows into the regulating anaerobic pool by itself. The sewage is homogenized and acidified in the regulating anaerobic pond. At the same time, it is mixed with the mixed liquid that enters the regulating anaerobic pond through the mixed liquid return pipe of the 4 dynamic membrane bioreactors, and occurs in the regulating anaerobic pond. Anoxic denitrification reaction and anaerobic phosphorus release reaction; the sewage from the anaerobic tank is adjusted to enter the reaction zone of the 1 dynamic membrane bioreactor through the water inlet pipe, and the compressed air enters the dynamic membrane bioreactor through the 4 aeration pipe. The reaction zone of the reactor is aerated with oxygen, and the microorganisms undergo nitrification reaction and aerobic phosphorus absorption reaction in the reaction zone 1 of the dynamic membrane bioreactor. The activated sludge after the aerobic phosphorus absorption is concentrated in the 3 sludge zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com