Mask plate territory for manufacturing connecting pore and its design method

A technology for manufacturing connections and design methods, which is applied in the field of mask template layout and design for manufacturing connection holes, can solve the problems of complex mask template manufacturing process and photolithography process, save time and economic cost, simple process, and improve consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

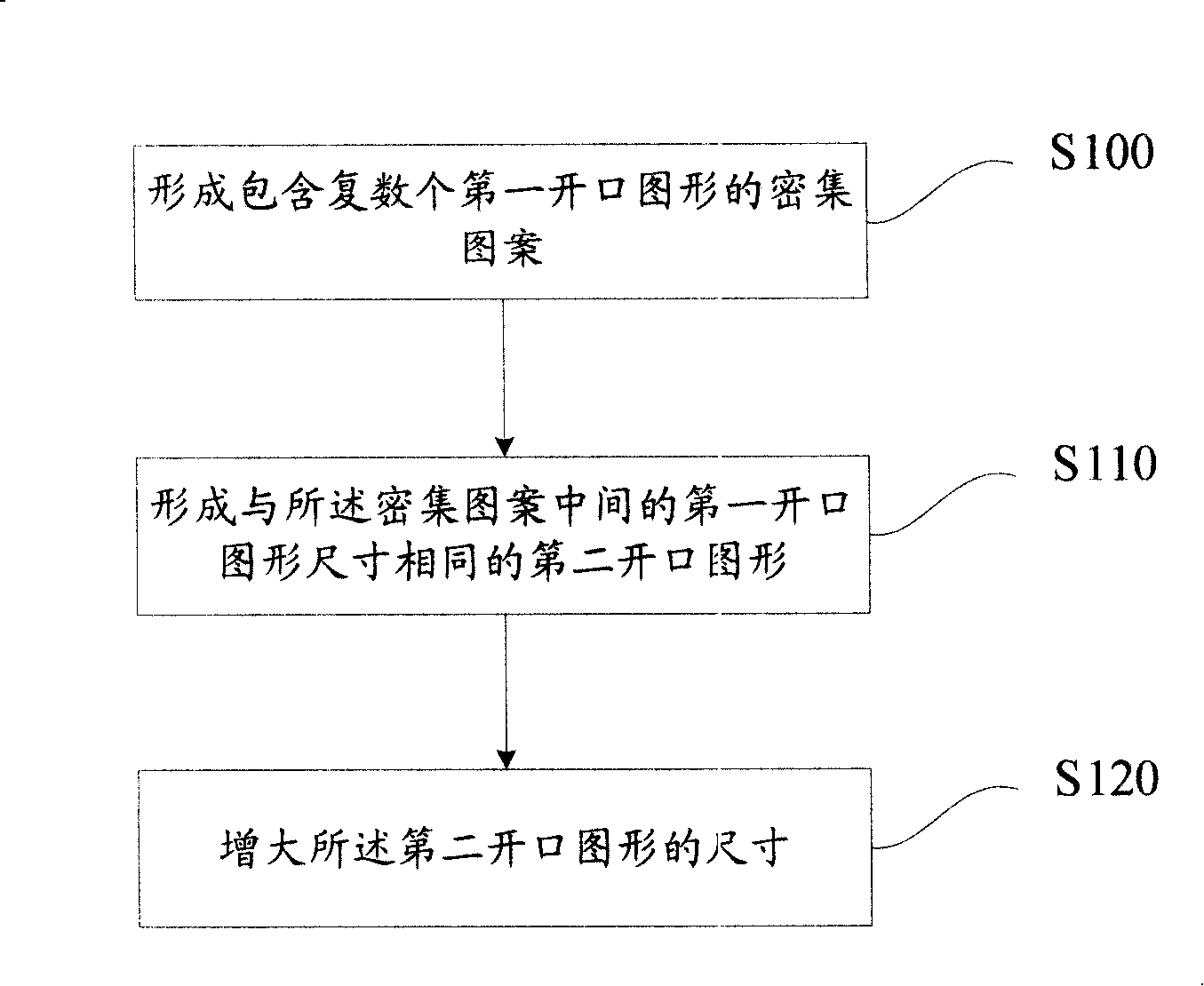

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

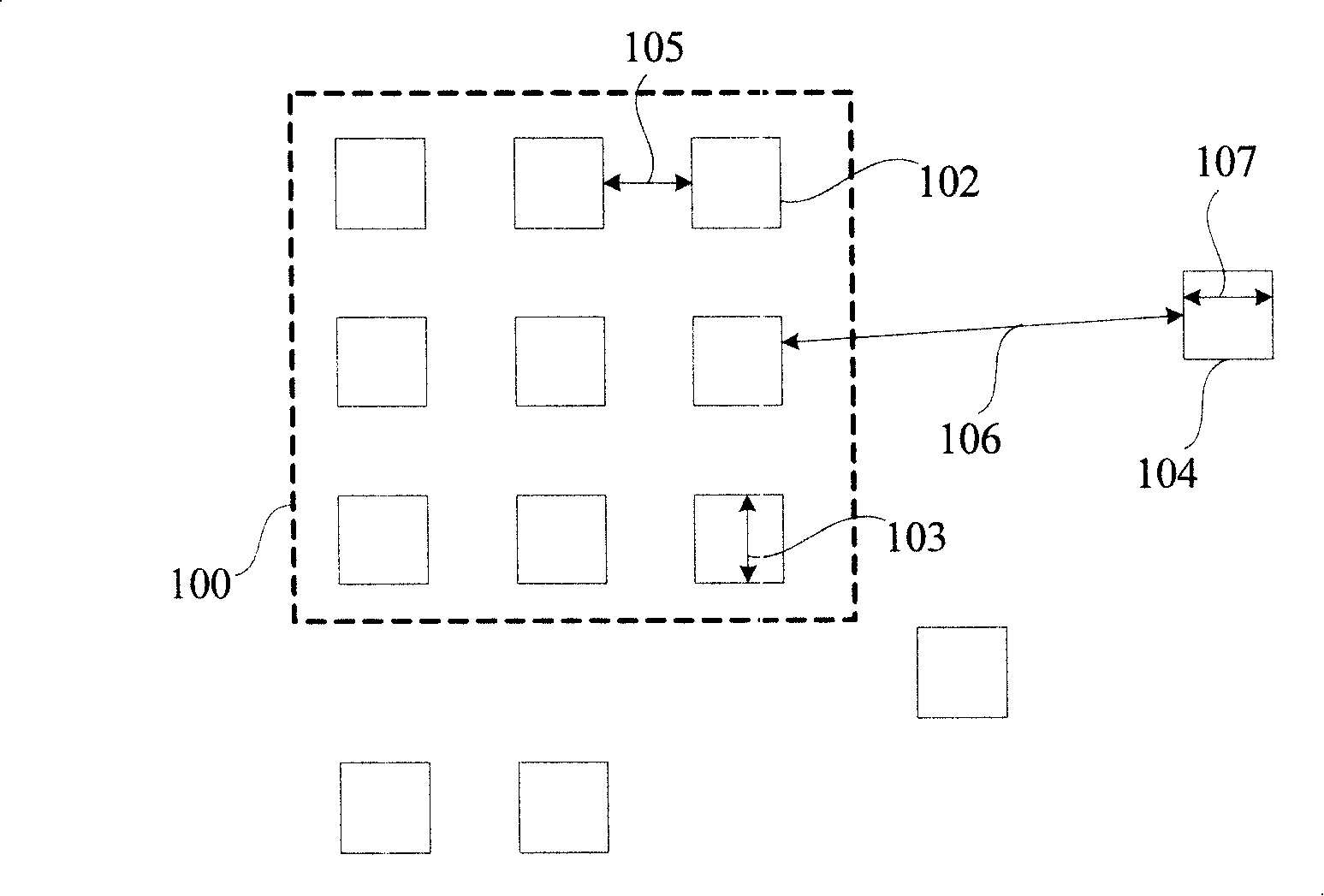

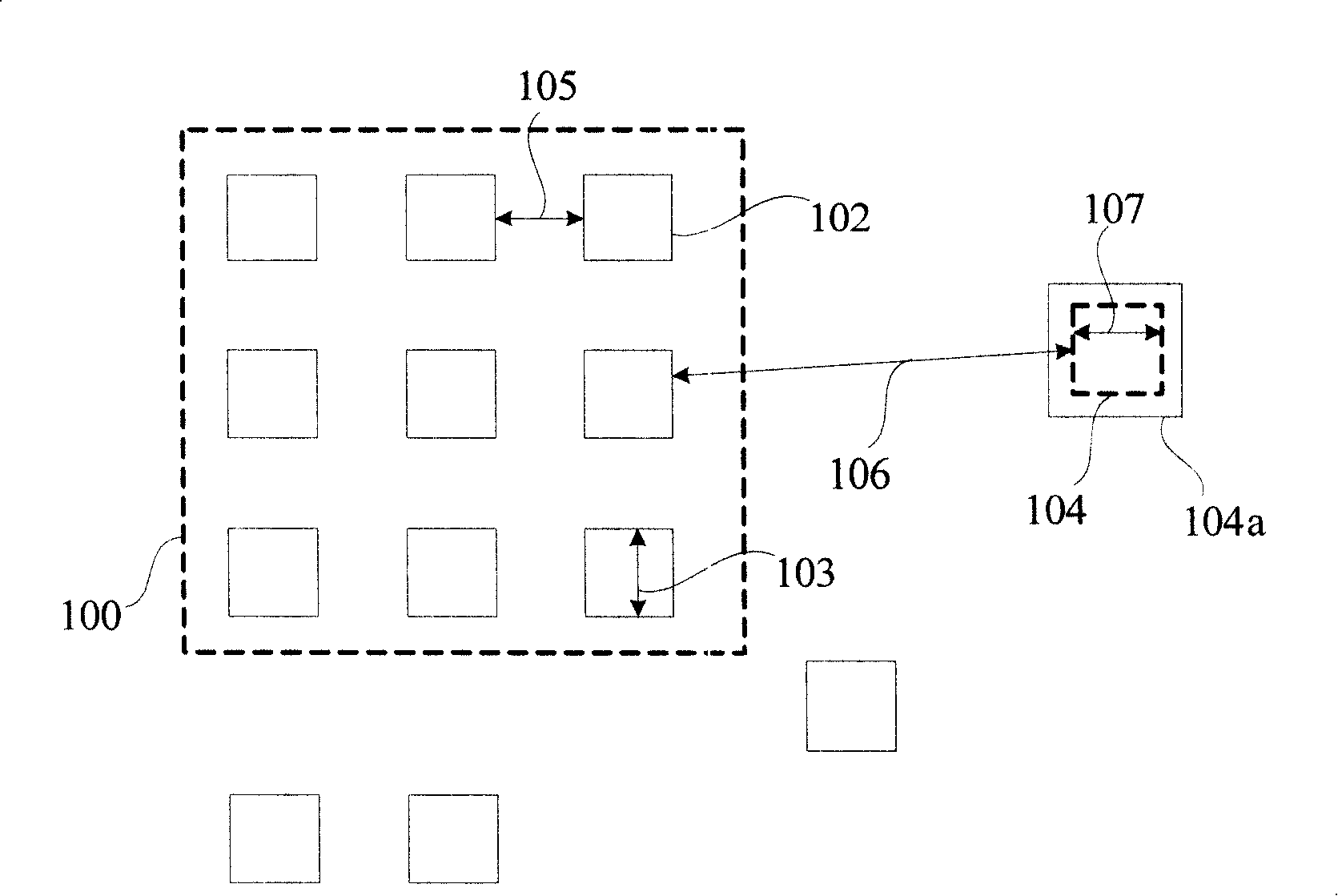

[0025] With the development of semiconductor manufacturing technology to smaller technology nodes, the requirements for the resolution of lithography process are getting higher and higher. The resolution of lithography can be improved through high-resolution exposure light source, advanced mask correction technology (OPC) and immersion exposure technology. At present, the resolution of optical lithography has reached 45nm or even smaller. The improvement of lithography resolution has brought another problem, that is, the reduction of focus depth, which means that lithography can only achieve the required resolution within a small focal length range, and the process parameters on the production line A slight deviation will cause the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com