Method for synthesizing fatty acid methyl ester

A technology of fatty acid methyl ester and synthesis method, which is applied in the field of obtaining ester substances through chemical modification of oil, can solve the problems of unfavorable large-scale production, environmental pollution of sulfuric acid, and high energy consumption, and achieves convenient large-scale continuous production technology and equipment. The effect of low corrosion and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

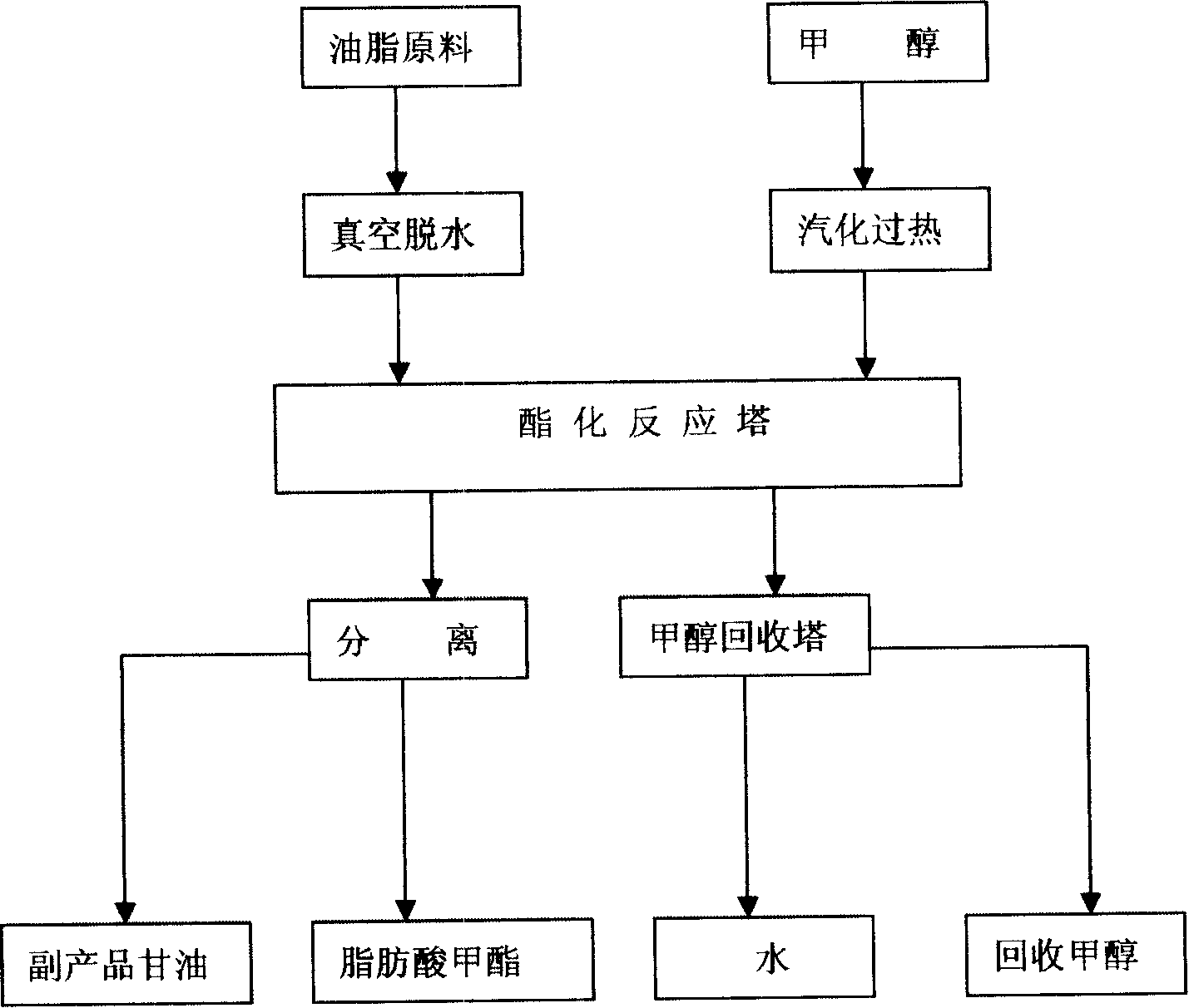

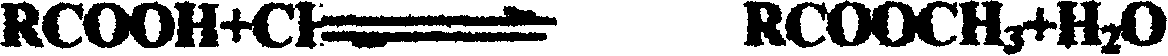

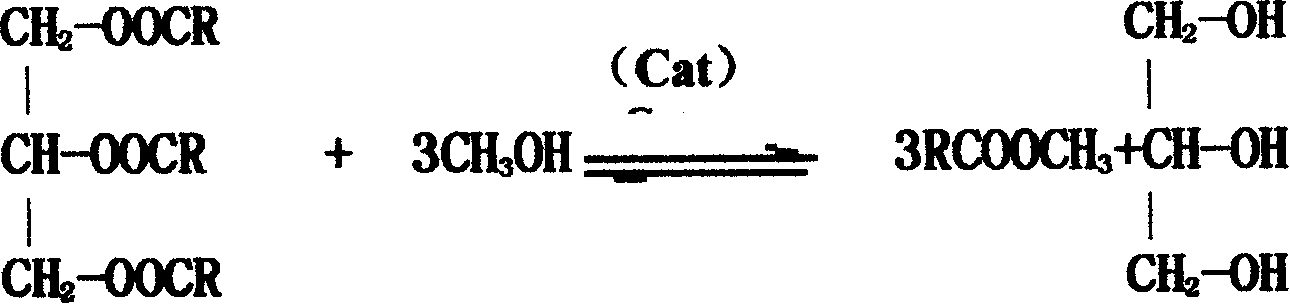

[0021] After the oil raw material is filtered to remove mechanical impurities, it enters the oil raw material storage tank. The oil raw material in the storage tank is transported by a pump, heated to 160°C by a preheater, dehydrated by a continuous vacuum flash dehydrator at -0.09Mpa, pressurized by a pump to 1~4Mpa, and heated to 110~240°C by a preheater , continuously enters the esterification reaction tower from the upper part, the raw material methanol is pressurized to 1-4Mpa with a pump, heated to 110-240°C after being vaporized, and continuously enters the esterification tower from the bottom of the esterification reaction tower through a gas distributor. The oil raw material is top-down, and the methanol vapor is in countercurrent contact with the bottom-up. Under the action of high temperature and pressure, hydrolysis, esterification, transesterification, stripping, absorption, rectification and other chemical reactions and chemical processes occur. The water produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com