Method for preparing cross-linked polymer

A technology of cross-linked polymers and polymers, applied in the field of polymer materials, can solve the problems of not conforming to the general direction of environmental friendliness and high energy consumption, and achieve the effect of low pressure, simple method and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

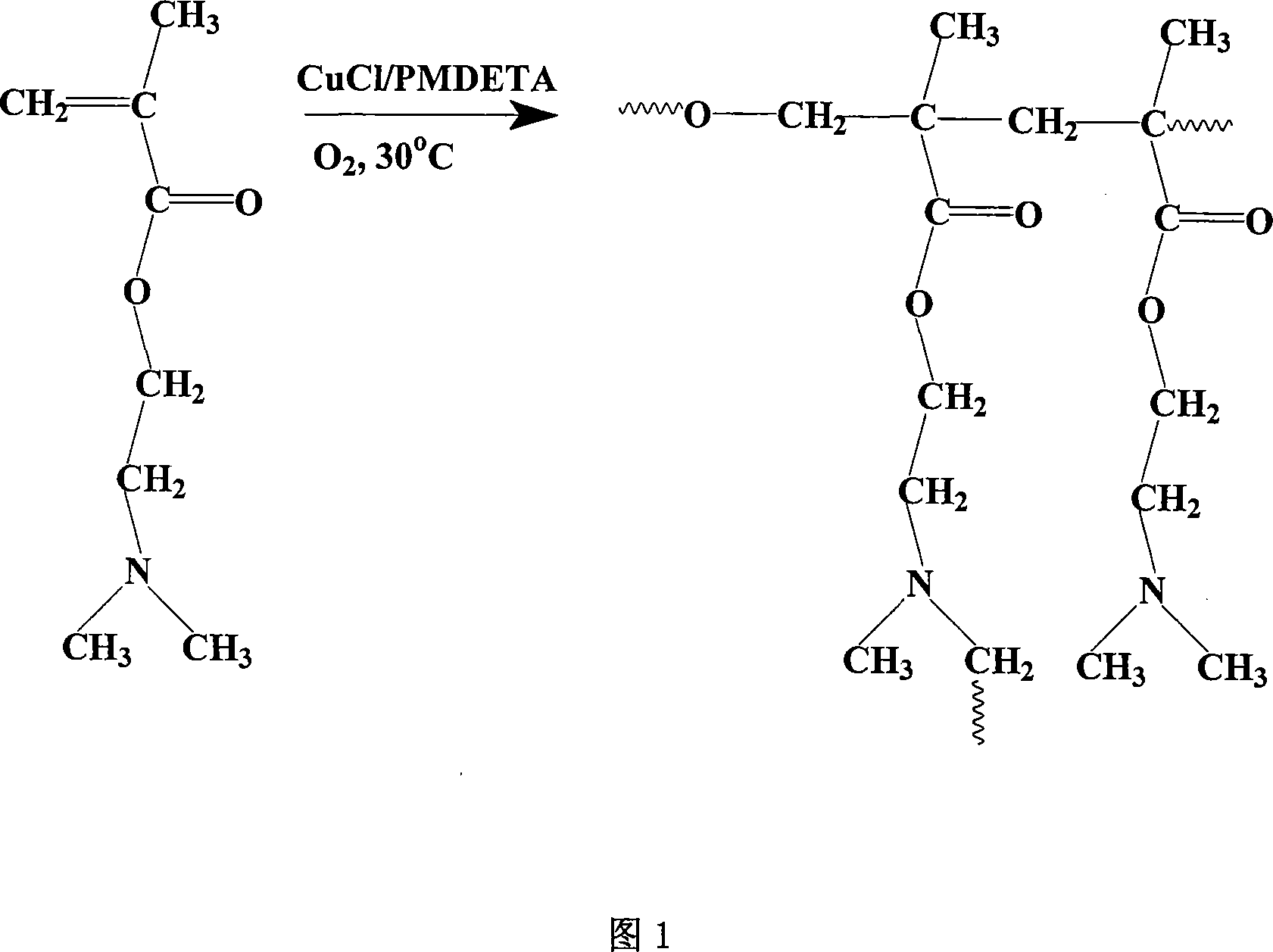

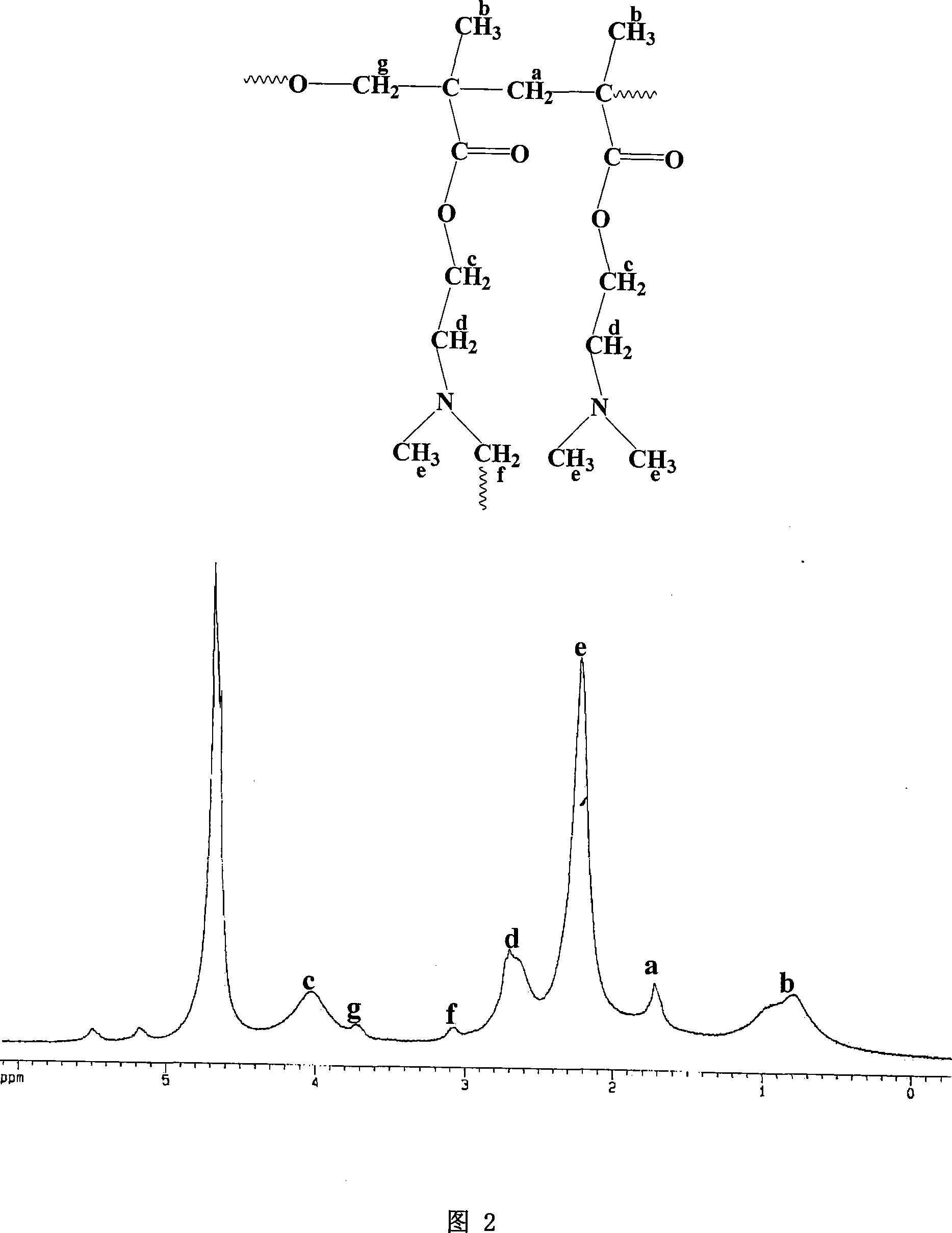

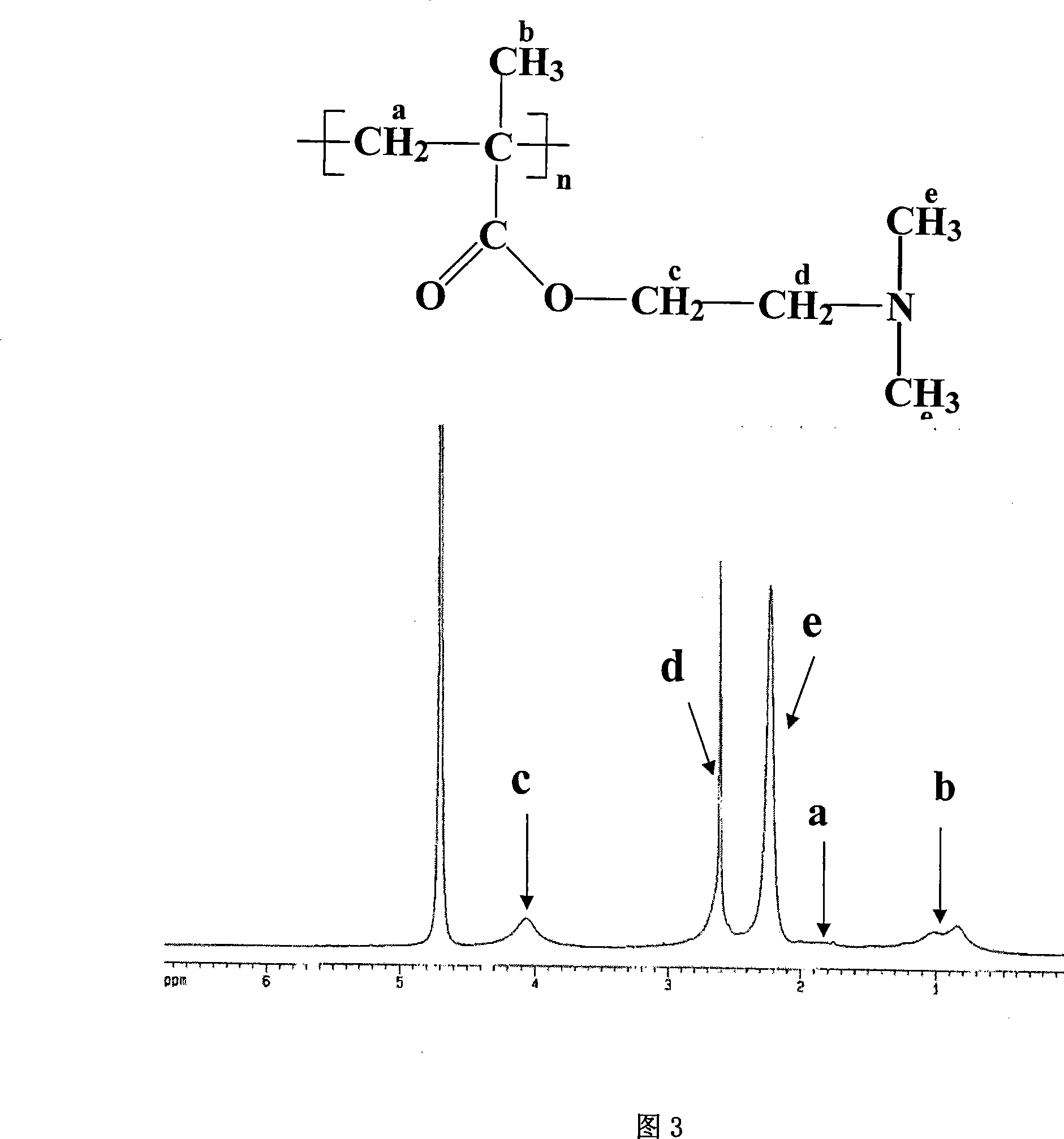

Method used

Image

Examples

Embodiment 1

[0015] Embodiment one: CuCl (1.4mg, 0.015mmol), PMDETA (7.7mg, 0.044mmol), DMAEMA (5ml, 0.03mol) and deionized water (20ml) are added in a beaker, and utilize water bath to make its reaction temperature Control at 30°C. After 24 hours, put the polymer solution in a 70°C water bath. After the polymer precipitates, take it out and put it in deionized water at room temperature, and then transfer it to a 70°C water bath. Repeat the treatment three times. As above, the filtered polymer was dried in an oven at 45° C. for 2 days to obtain a white or light yellow product weighing about 1.3 grams. The water absorption ratio in deionized water measured by the saturated swelling method is 26.6.

Embodiment 2

[0016] Embodiment two: CuCl (2.9mg, 0.029mmol), PMDETA (15.3mg, 0.088mmol), DMAEMA (10ml, 0.059mol) and deionized water (23.3ml) are added in a beaker, and utilize water bath to make it react The temperature is controlled at 30°C. After 24 hours, put the polymer solution in a 70°C water bath. After the polymer precipitates, take it out and put it in deionized water at room temperature, then transfer it to a 70°C water bath, and repeat the process. More than three times, the filtered polymer was dried in an oven at 45°C for 3 days to obtain a white or light yellow product weighing about 2.2 grams. The water absorption ratio in deionized water measured by the saturated swelling method is 37.9.

Embodiment 3

[0017] Embodiment three: CuCl (4.4mg, 0.044mmol), PMDETA (22.9mg, 0.13mmol), DMAEMA (15ml, 0.088mol) and deionized water (22.5ml) are added in a beaker, and utilize water bath to make it react The temperature is controlled at 30°C. After 24 hours, put the polymer solution in a 70°C water bath. After the polymer precipitates, take it out and put it in deionized water at room temperature, then transfer it to a 70°C water bath, and repeat the process. More than three times, the filtered polymer was dried in an oven at 45°C for 3 days to obtain a white or light yellow product weighing about 3.7 grams. The water absorption ratio in deionized water measured by the saturated swelling method is 24.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com