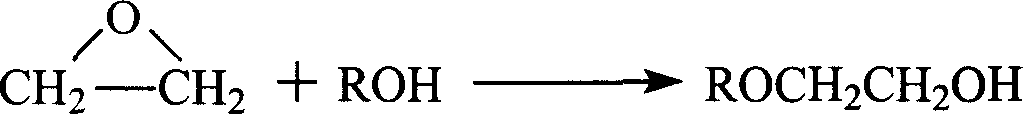

Method for preparing ethylene glycol ether

A glycol ether and aliphatic alcohol technology, applied in the field of glycol ether preparation, can solve the problems of low selectivity of glycol ether, no catalyst stability, high molar ratio of alcohol/ethylene oxide, etc., to achieve High selectivity, excellent reaction performance, and low alcohol-to-alkane ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

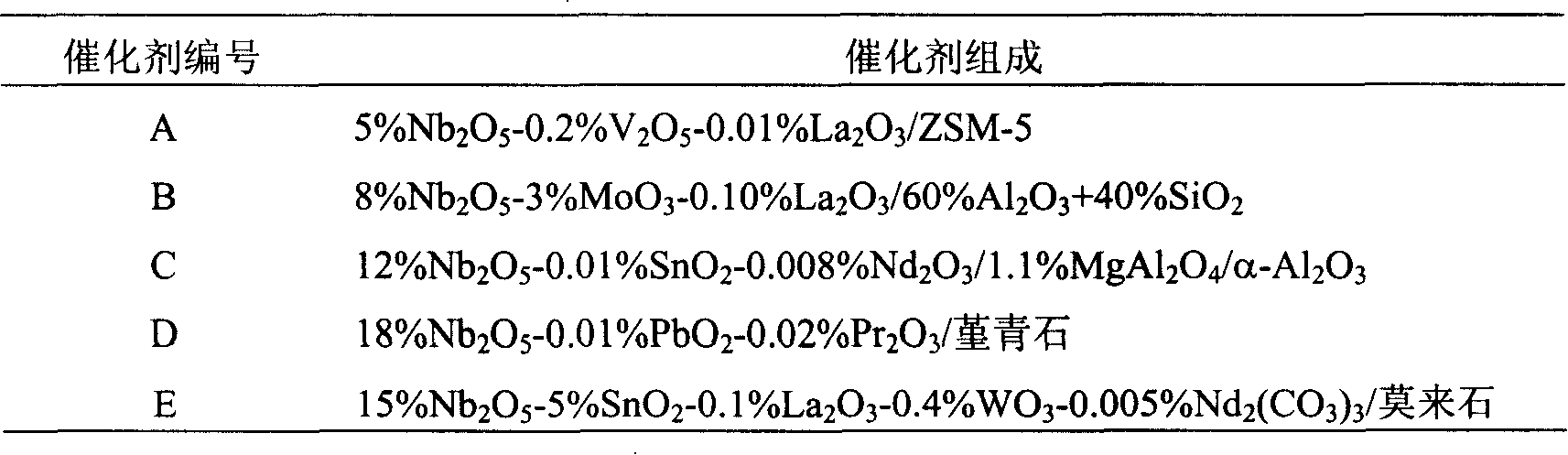

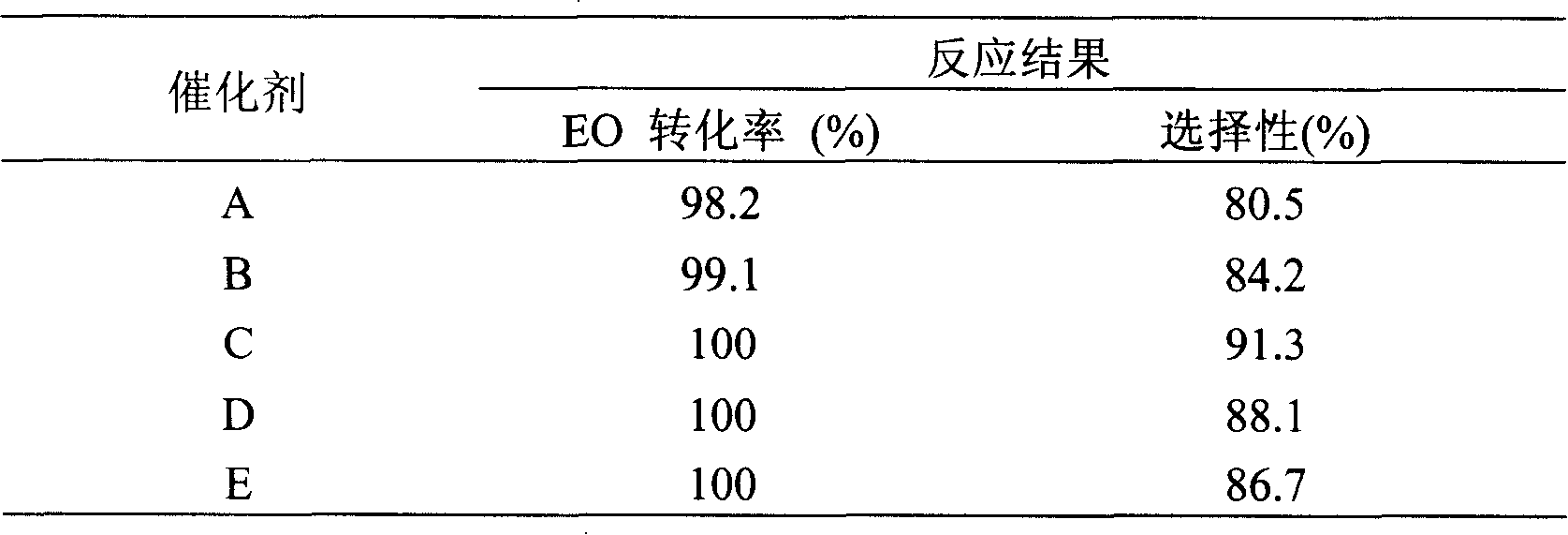

Embodiment 1

[0032] 100 g of ZSM-5 zeolite (SiO 2 / Al 2 o 3 Molar ratio 60, ammonium type) add 65 milliliters of 10% (weight) dilute nitric acid, fully knead in the kneader, form agglomerate material, extrude molding, dry at 150 ℃ for 2 hours, 800 ℃ roast for 4 hours, obtain Strip carrier. The niobium oxalate solution was impregnated on the prepared ZSM-5 carrier, and dried at 120°C for 2 hours; then the ammonium metavanadate was dissolved in 5% (weight) hydrogen peroxide, impregnated on the catalyst again, and dried at 120°C for 2 hours; Finally, lanthanum trichloride aqueous solution was impregnated on the catalyst, dried at 120°C for 2 hours, and calcined in air at 400°C for 4 hours to obtain catalyst A, whose composition is shown in Table 1.

Embodiment 2

[0034] Fully mix 67.6 grams of aluminum hydroxide, 40 grams of silicon dioxide, and 4 grams of cyclodextrin, then add 60 milliliters of 4% (weight) dilute nitric acid, fully knead in a kneader to form a lump material, and extrude , dried at 150°C for 2 hours, and calcined at 1400°C for 4 hours to obtain a strip-shaped carrier. Use a certain concentration of ammonium molybdate solution of 125 mmol / ml to impregnate the above-mentioned carrier at room temperature, the volume ratio of impregnated liquid to solid is 2:1, impregnate for 2 hours, filter the solution, and dry in vacuum at 120°C for 2 hours; then use a certain 15% niobium ammonium complex solution (NH 4 [NbO(C 2 o 4 )2 (H 2 O) 2 ]·(H 2 O) n ) continue to impregnate the above-mentioned treated carrier at room temperature, the volume ratio of impregnation liquid to solid is 2:1, the impregnation time is 2 hours, the solution is filtered off, and vacuum-dried at 120°C for 2 hours, so impregnation is carried out thre...

Embodiment 3

[0036] Fully mix 113 grams of aluminum hydroxide powder, 5 grams of graphite, and 5 grams of squash powder, then add 60 milliliters of 4% (weight) dilute nitric acid, fully knead in a kneader to form a lump material, and extrude , dried at room temperature for 24 hours, dried at 150°C for 2 hours, and calcined at 1200°C for 4 hours to obtain strip-shaped α-Al 2 o 3 carrier. Impregnating α-Al with a mixed solution of magnesium nitrate and aluminum nitrate 2 o 3 Carrier, dried at 150°C for 2 hours, and calcined again at 1200°C for 4 hours to obtain MgAl 2 o 4 / α-Al 2 o 3 carrier. Immerse the carrier with a neodymium chloride aqueous solution with a concentration of 39.88 mg / ml at room temperature for 2 hours, the liquid-solid volume ratio is 2.5:1, filter the solution, and dry it in vacuum at 120° C. for 2 hours to obtain the carrier 1; Carrier 1 was continuously impregnated in vacuum with a liquid-to-solid volume ratio of 2.0:1, the solution was filtered off, and vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com