Separation utilization method for preparing ethene by-product C9+ fractioning by cracking

A technology of cracking to produce ethylene and by-products, applied in distillation purification/separation, organic chemistry, etc., can solve the problems of intensified polymerization and coke reaction, failure to extract DCPD, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

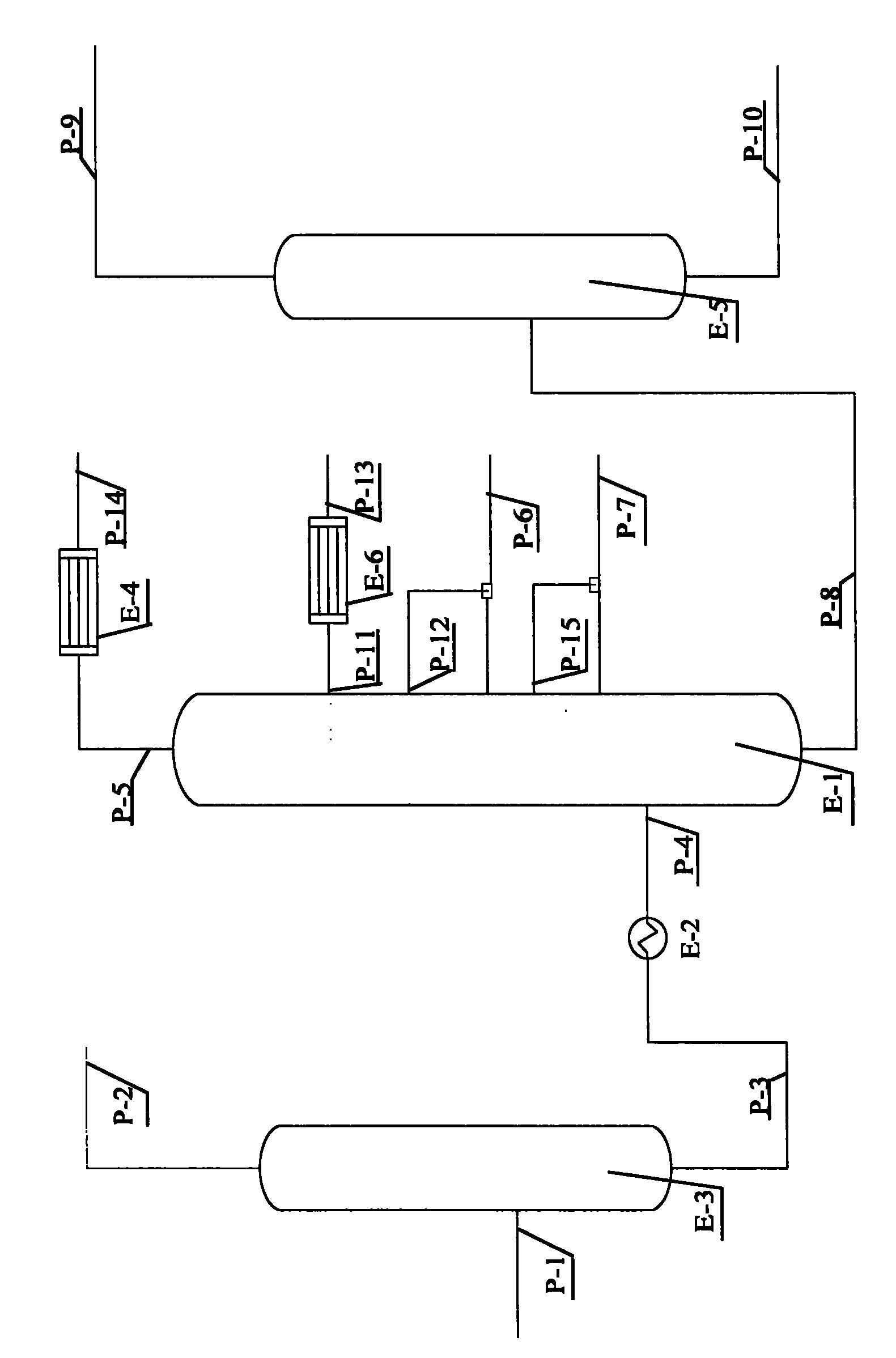

Method used

Image

Examples

example 1

[0029] According to the flow chart in Figure 1, the cracking C with the composition shown in Table 1 heated to 90°C 9 + The distillate is sent to vacuum rectification tower E-3 at a speed of 50g / h, the pressure of the control tower is 0.01MPa, the temperature at the top of the tower is 60-70°C, and the temperature at the bottom of the tower is 95-105°C. The styrene fraction obtained at the top of the tower was distilled out at a rate of 8g / h, and the contents of its main components are shown in Table 2. The bottom cut is discharged from the vacuum rectification tower at a rate of 42g / h, and the main component content of the bottom cut is shown in Table 3.

[0030] The bottom fraction is heated to 220°C by heat exchanger E-2 for 20 minutes, and then sent to atmospheric distillation column E-1. The temperature at the top of the atmospheric distillation tower is controlled at 40-42° C., so that cyclopentadiene, which has the lowest boiling point, is distilled from the top of th...

example 2

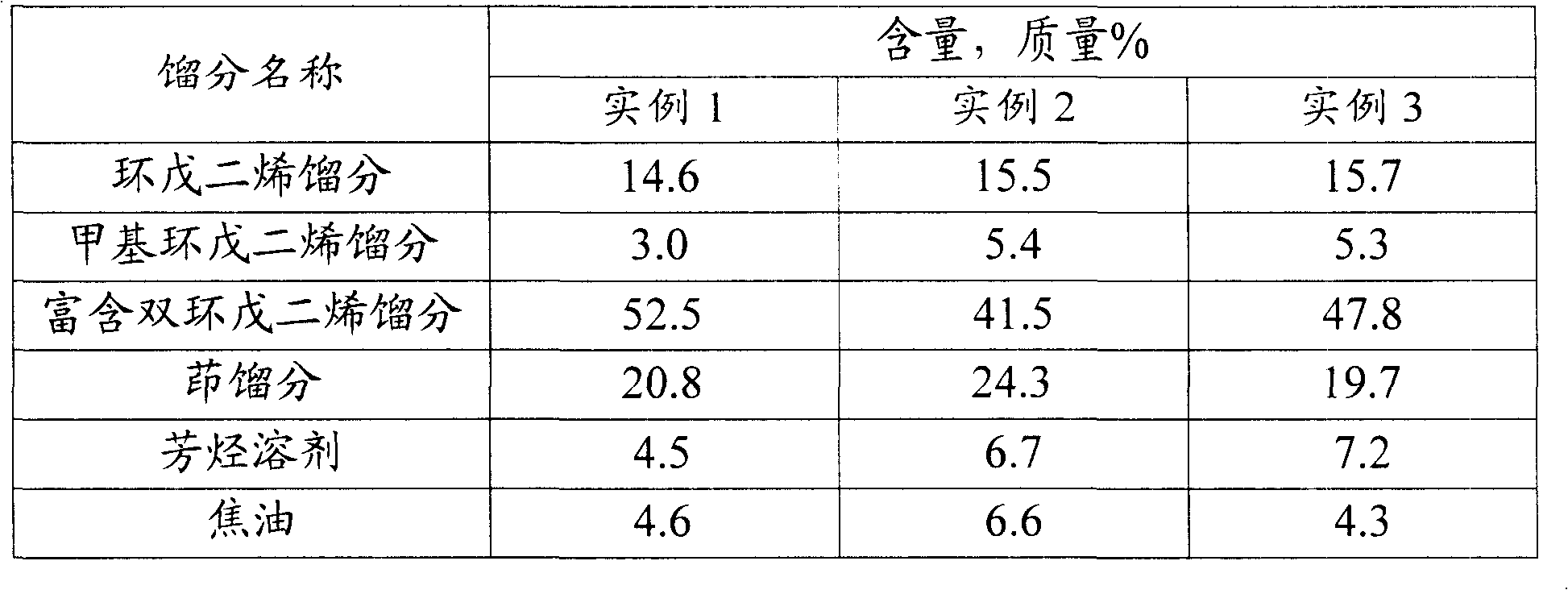

[0032] Isolation and cracking C by the method of example 1 9 + Distillate, the difference is that the bottom fraction of vacuum distillation tower E-3 is heated to 260 °C and then sent to atmospheric distillation tower E-1, and the reflux ratio of the second side line of atmospheric distillation tower is controlled to be 2:1 . The contents of each fraction obtained by atmospheric distillation and the second vacuum distillation are shown in Table 4, and the main substance contents of each fraction are shown in Table 5.

example 3

[0034] Isolation and cracking C by the method of example 1 9 + The different components of the fraction are that the indene fraction from the third side stream of the atmospheric rectification tower is condensed and partly refluxed with a reflux ratio of 2:1, partly discharged from the pipeline P-7. The contents of each fraction obtained by atmospheric distillation and the second vacuum distillation are shown in Table 4, and the main substance contents of each fraction are shown in Table 5.

[0035] Table 1

[0036] component name

Content, mass%

0.52

[0037] component name

Content, mass%

0.19

0.10

-

-

p-, m-xylene

-

7.79

O-xylene

2.45

propenylbenzene

-

-

methyl ethyl benzene

1.73

C 9 Aromatics

1.90

C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com