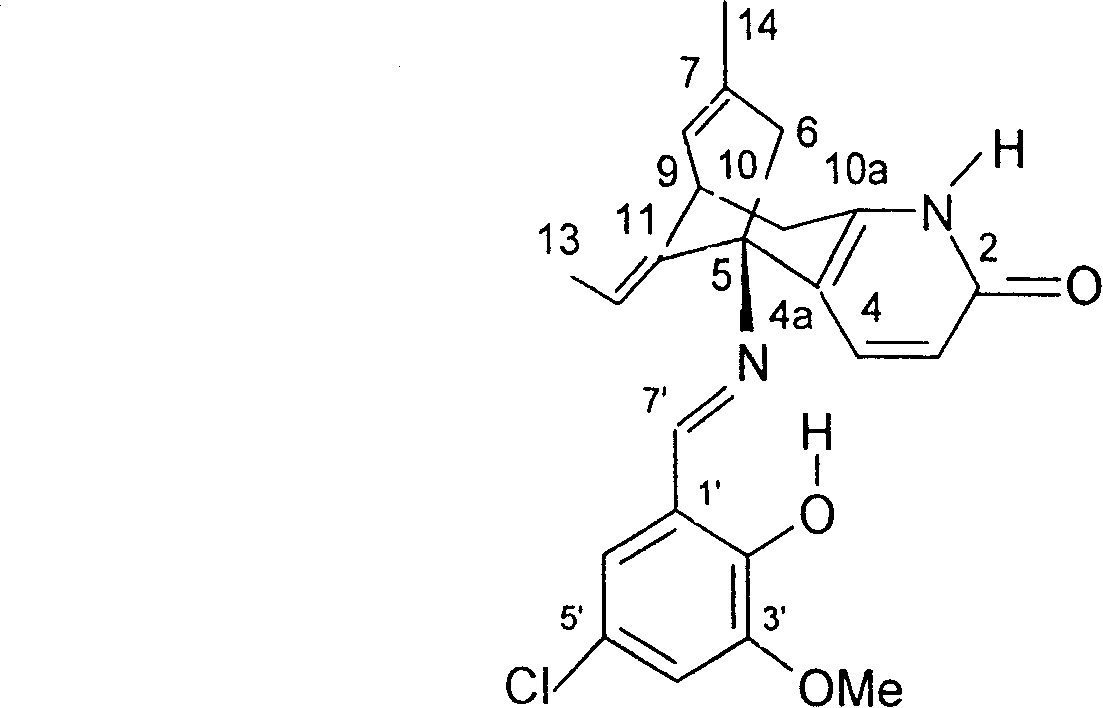

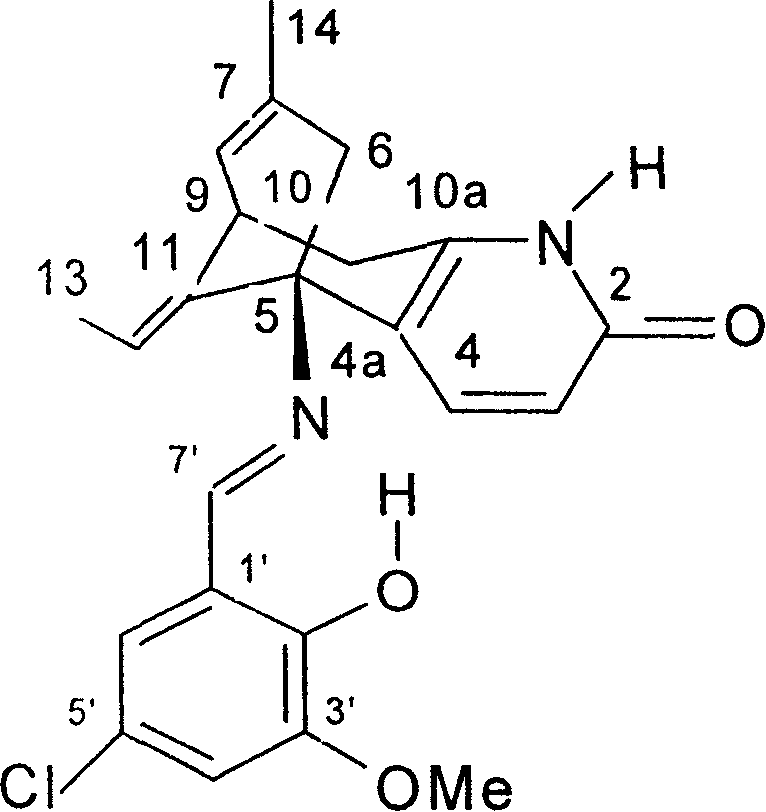

Huperzine A derivative xipulin preparations

A technology of huperzine A and its derivatives, which is applied in the field of huperzine A derivative Xipulin preparations, can solve the problems of low selectivity of acetylcholinesterase, unsatisfactory curative effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Make 1000 pieces of Xipulin tablets with the raw materials in the following weight ratio, and the weight of the tablet is 90mg

[0028] Shiplin 0.25g

[0029] Lactose 55g

[0030] Microcrystalline Cellulose 22g

[0031] Sodium Lauryl Sulfate Appropriate amount

[0032] Sodium carboxymethyl starch 10g

[0034]

[0035] Made into 1000 pieces

[0036] Preparation Process:

[0037] 1. Grind and mix Shiplin raw material with sodium lauryl sulfate.

[0038] 2. Gradually sieve and mix Shipulin with lactose and microcrystalline cellulose according to the method of equal increase, and granulate by dry method.

[0039] 3. Add sodium carboxymethyl starch and magnesium stearate, mix well, and press into tablets.

Embodiment 2

[0041] Make 1000 Xipulin capsules with the raw materials in the following weight ratio, each weighing about 90mg

[0042] Shiplin 0.5g

[0043] 45g pregelatinized starch

[0044] Microcrystalline Cellulose 35g

[0045] Sodium Lauryl Sulfate 0.5g

[0046] Sodium carboxymethyl starch 6g

[0047] Micronized silica gel 1g

[0049]

[0050] Make 1000 capsules

[0051] Preparation Process:

[0052] 1. Grind and mix Shiplin raw material with sodium lauryl sulfate.

[0053] 2. Gradually sieve and mix Shipulin with pregelatinized starch and microcrystalline cellulose according to the method of equal increment, and granulate by dry method.

[0054] 3. Add sodium carboxymethyl starch and magnesium stearate, mix well, pack into capsules, and get ready.

Embodiment 3

[0056] Make 1000 dispersible tablets of Shipulin with the raw materials in the following weight ratio, each weighing about 90mg

[0057] Shiplin 1g

[0058] Pregelatinized starch 42g

[0059] Microcrystalline Cellulose 25g

[0060] Polyvinylpyrrolidone 5g

[0061] Sodium Lauryl Sulfate 1g

[0062] Sodium carboxymethyl starch 15g

[0064]

[0065] Made into 1000 pieces

[0066] Preparation Process:

[0067] 1. Grind and mix Shiplin raw material with sodium lauryl sulfate.

[0068] 2. Gradually sieve and mix Shipulin with pregelatinized starch, microcrystalline cellulose, and polyvinylpyrrolidone according to the method of equal increments, and granulate by dry method.

[0069] 3. Add sodium carboxymethyl starch and magnesium stearate, mix well, and press into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com