Chip resistor and its manufacturing method

A chip resistor and manufacturing method technology, applied in the direction of resistor manufacturing, resistors, thick film resistors, etc., can solve the problems such as impact applied by chip resistor 1, insufficient solder connection strength, damage, etc., to protect the appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

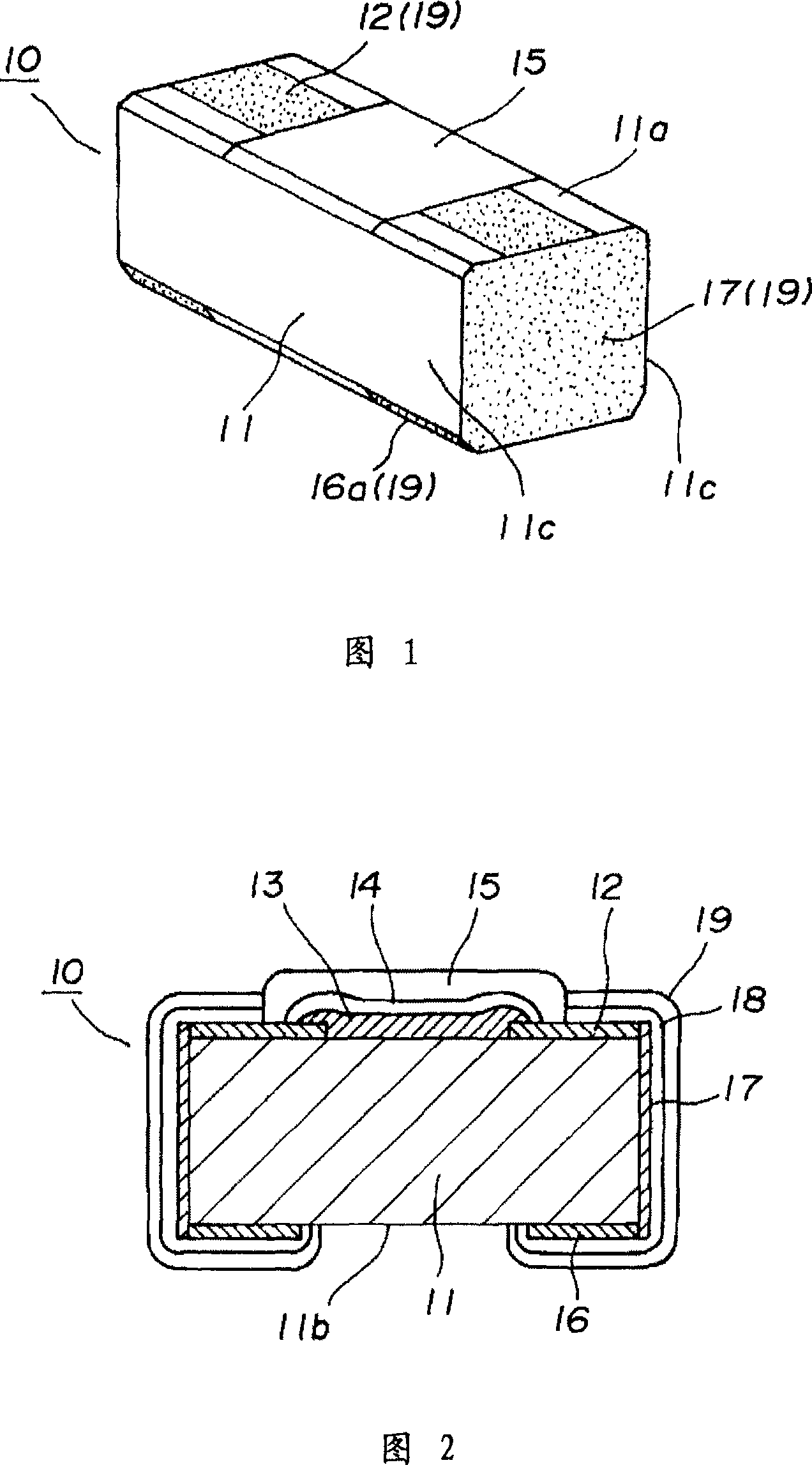

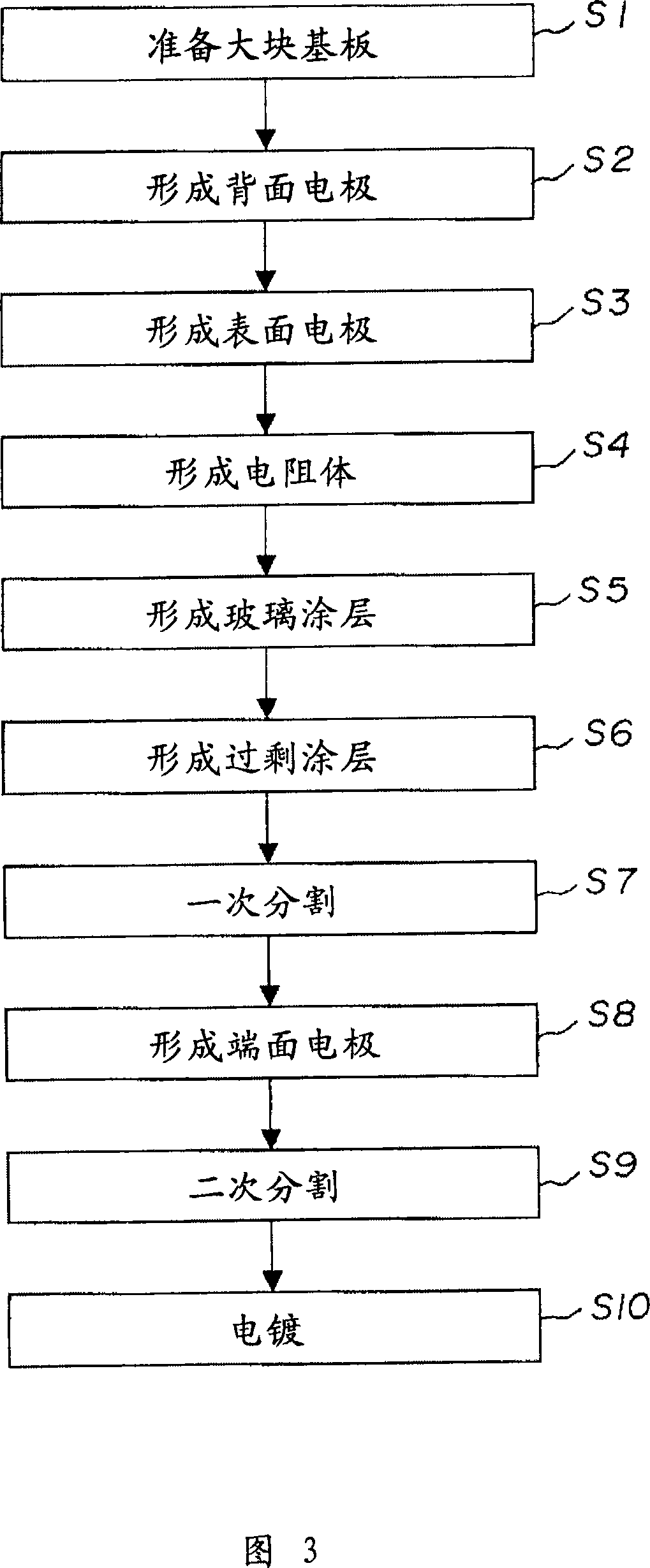

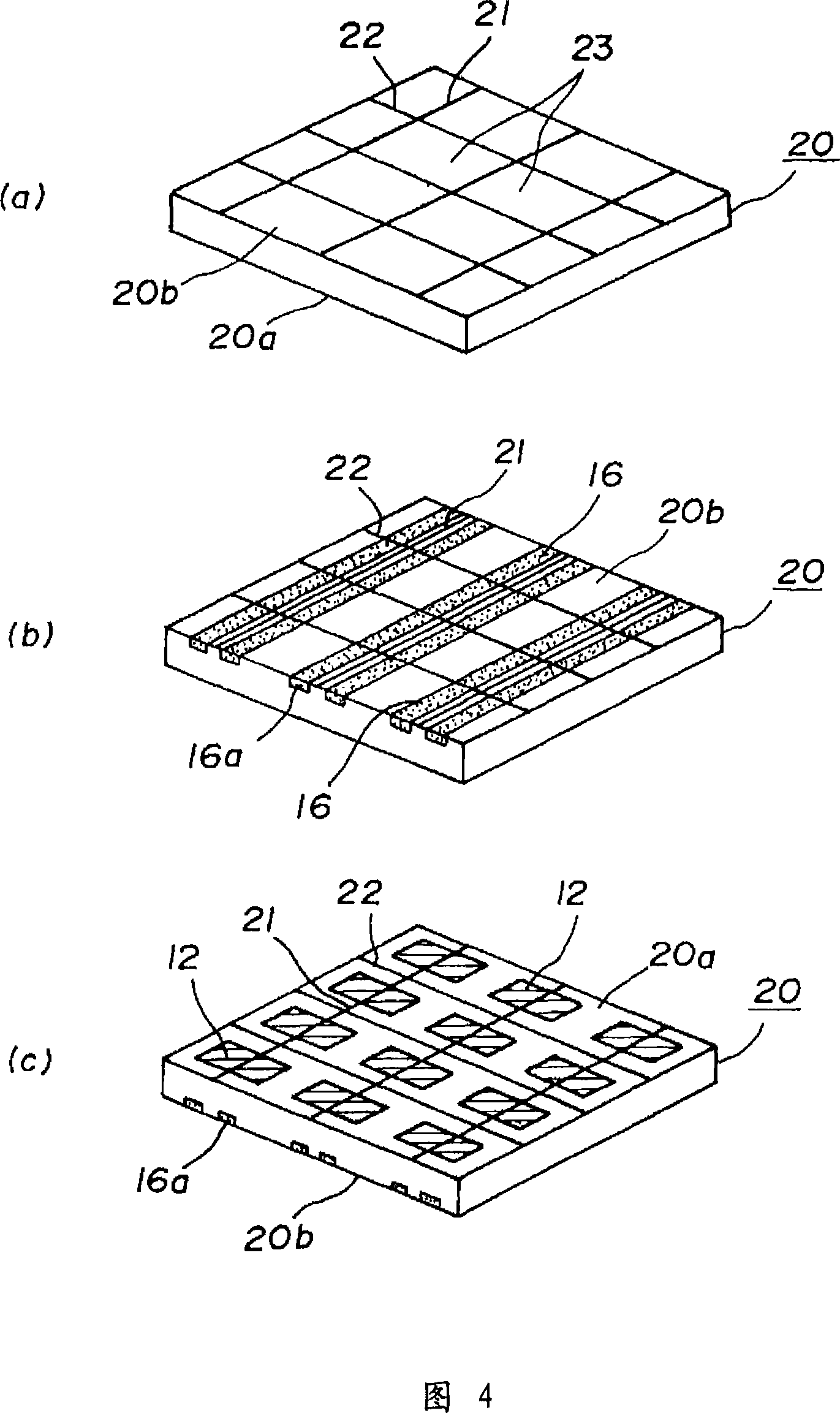

[0019] Embodiments of the present invention will be described with reference to the accompanying drawings. FIG. 1 is a perspective view of a chip resistor according to an example of this embodiment, FIG. 2 is a cross-sectional view schematically showing the chip resistor, and FIG. 3 is a diagram showing a manufacturing process of the chip resistor. 4 to 6 are explanatory diagrams showing the manufacturing method of the chip resistor in the order of steps, FIG. 7 is an explanatory diagram showing the state that the chip resistor is supplied to the sample in two different postures, and FIG. 8 is A side view showing a state in which the chip resistor is mounted on a solder pad in a lateral orientation.

[0020] The chip resistor 10 shown in these figures is a rectangular chip resistor corresponding to a multi-mounting method. A plurality of nozzles are sucked and mounted on the solder pads 33 of the circuit board 32 (see FIGS. 7 and 8 ). As shown in FIGS. 1 and 2 , the chip resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com