A dual-frequency ultra-thin highly directional resonance cavity antenna

A resonant cavity antenna, high directional technology, applied in resonant antennas, resonant antenna parts, antennas and other directions, can solve the problems of single-frequency operation, limitation, etc., and achieve the effect of high gain and high directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

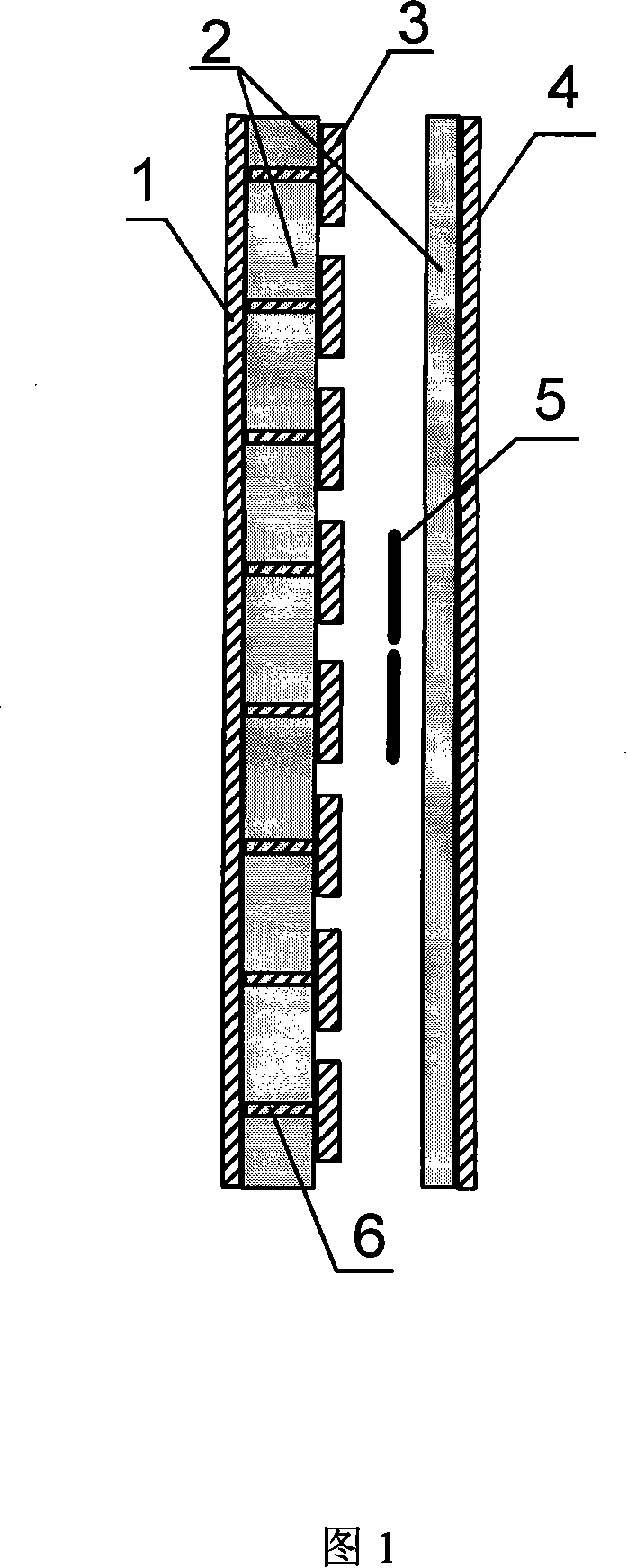

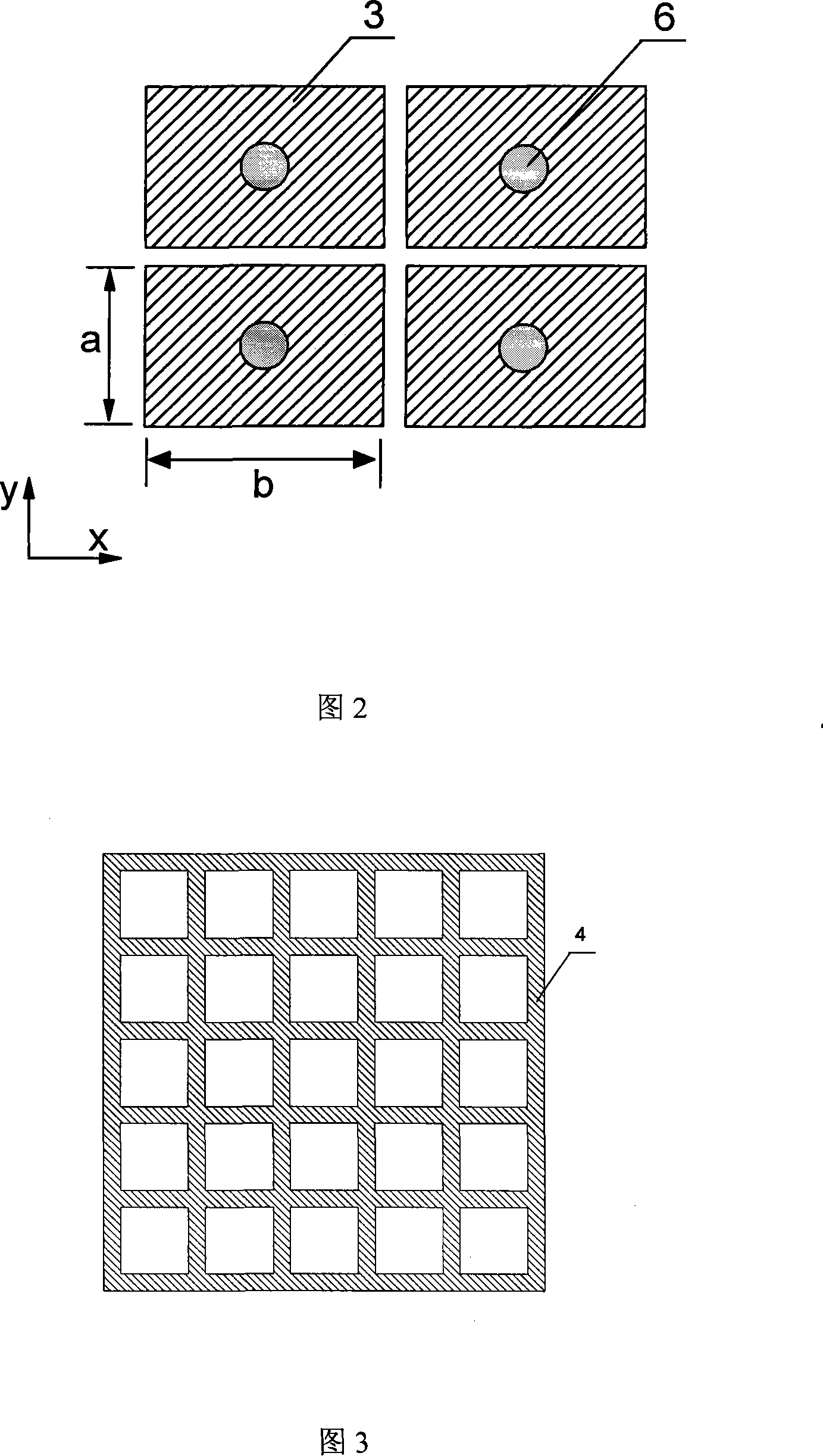

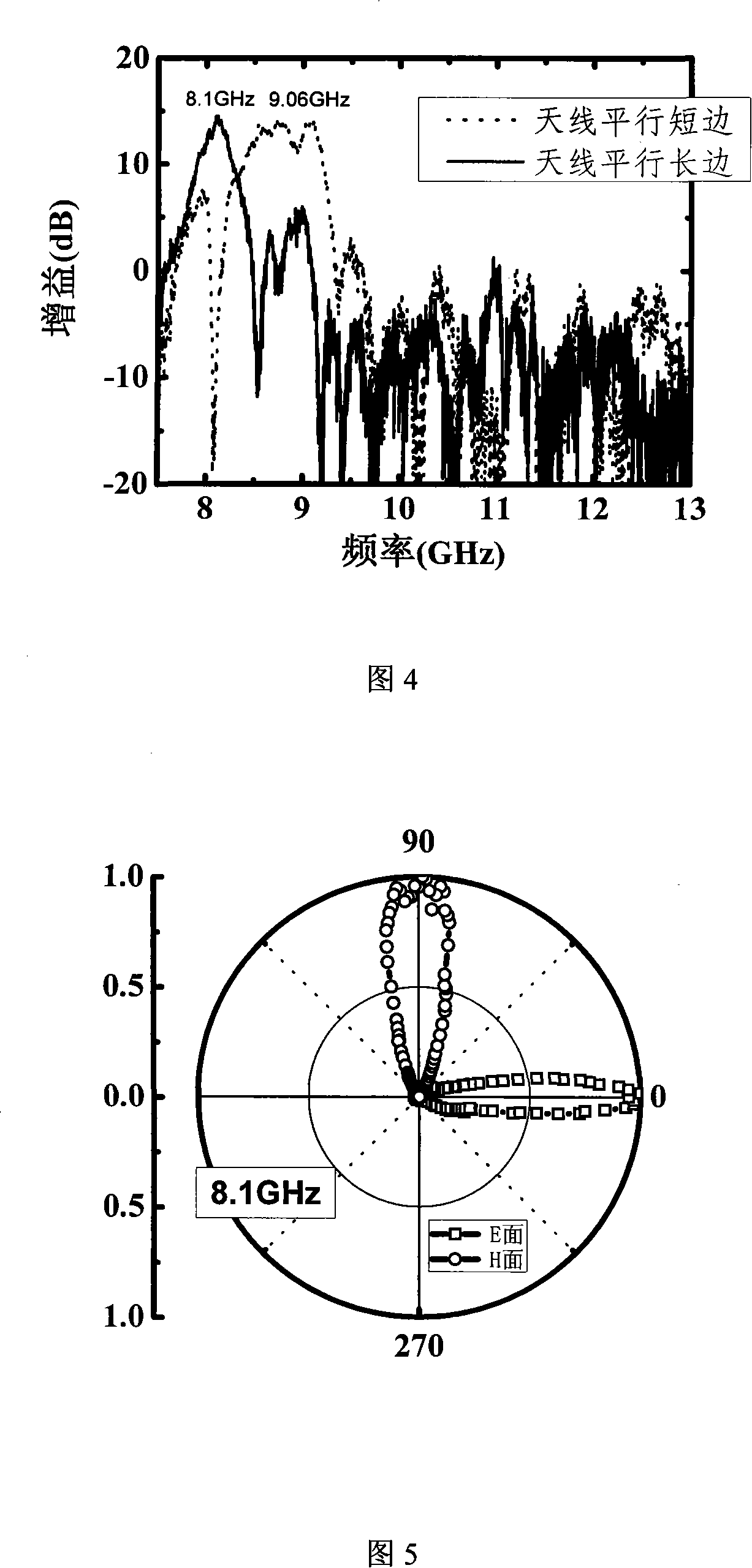

[0020] Please refer to the attached figure 1 , with figure 2 .

[0021] The present invention comprises a high-impedance surface, a metal grid layer 4 and a microwave feed source 5 between the two, the metal grid layer 4 is a common commercially available single-sided printed circuit board made by itself, and its dielectric layer 2 has a thickness of 0.8 mm. On the surface of the commercially available single-sided printed circuit board, a metal grid with a period smaller than the operating frequency is self-produced, which acts as a common reflector, but this reflector allows a small amount of electromagnetic wave transmission. The microwave feed source 5 is a commercially available dipole antenna or monopole antenna or other commonly used microwave feed sources. The high-impedance surface is an anisotropic high-impedance surface, and the anisotropic high-impedance surface is composed of a metal layer 1 on the lower surface, a dielectric layer 2 in the middle, and an arra...

Embodiment 2

[0023] The present invention whose size is 200X200 square millimeters is made, except that the anisotropic high-impedance surface is composed of the metal layer 1 on the lower surface, and the anisotropic resonant unit 3 on the upper surface is composed of an I-shaped structure array, and the microwave feed source 5 adopts a Except for the monopole antenna at about 10 GHz, the rest of the structure is the same as that of Embodiment 1.

[0024] The dipole antenna's vibrator is parallel to the I-shaped parting and perpendicular to the I-shaped parting to measure the gain spectrum and pattern of the antenna. The gain spectrum of the measured forward radiation is that when the antenna is parallel to the I-shaped and perpendicular to the I-shaped, we get the maximum gain values of 4.5GHz and 6.1GHz. Corresponding to two different operating frequencies of parallel and vertical polarization respectively. The directivity diagrams of these two frequencies were measured, and the resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com