Magnesium alloy and polyphenylene sulfide plastic direct bonding method

A polyphenylene sulfide and magnesium alloy technology, applied in the direction of electrolytic organic material coating, etc., can solve problems such as being unsuitable for large-area plastic and metal bonding, affecting the bonding performance of plastic and metal, and not specifically mentioning magnesium alloy bonding. The effect of tight bonding, easy promotion and application, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The substrate metal used for the organic coating is a Mg-Al-Zn series magnesium alloy with a size of 50×10×1 (mm).

[0039] Step 1: Organic Coating

[0040] Firstly, the magnesium alloy samples were pre-polished, then ultrasonically degreased in acetone solution for 30 minutes at a temperature of 30°C, and then organic coating was performed. The specific process conditions and steps are as follows:

[0041] 1. The organic coating adopts a three-electrode working method, the working electrode is a magnesium alloy sample, the auxiliary electrode is a stainless steel sheet, and the reference electrode is a saturated calomel electrode (SCE);

[0042] 2. The electrolyte solution used in organic coating is composed of the following substances:

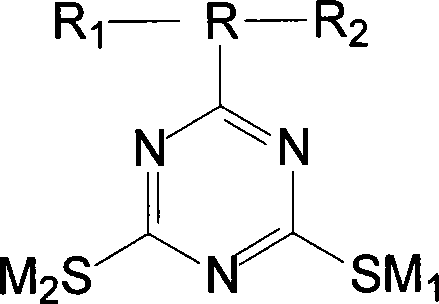

[0043]

[0044] 2mmol / L triazazine organic compound salt containing the above functional groups, 1mol / L sodium borate, and the rest distilled water;

[0045] 3. The organic coating conditions are as follows:

[0046] The pH valu...

Embodiment 2

[0051] The substrate metal used for the organic coating is a Mg-Zn series magnesium alloy with a size of 50×10×1 (mm).

[0052] Step 1: Organic Coating

[0053] Firstly, the magnesium alloy samples were pre-polished, then ultrasonically degreased in acetone solution for 30 minutes at a temperature of 30°C, and then organic coating was performed. The specific process conditions and steps are as follows:

[0054] 1. The organic coating adopts a three-electrode working method, the working electrode is a magnesium alloy sheet, the auxiliary electrode is a stainless steel sheet, and the reference electrode is a saturated calomel electrode (SCE);

[0055] 2. The electrolyte solution used in organic coating is composed of the following substances:

[0056]

[0057] 10mmol / L triazazine organic compound salt containing the above functional groups, 2mol / L sodium hydroxide, and the rest are distilled water;

[0058] 3. The organic coating conditions are as follows:

[0059] The pH ...

Embodiment 3

[0064] The substrate metal used for the organic coating is a Mg-Al-Mn series magnesium alloy with a size of 50×10×1 (mm).

[0065] Step 1: Organic Coating

[0066] Firstly, the magnesium alloy samples were pre-polished, then ultrasonically degreased in acetone solution for 30 minutes at a temperature of 30°C, and then organic coating was performed. The specific process conditions and steps are as follows:

[0067] 1. The organic coating adopts a three-electrode working method, the working electrode is a magnesium alloy sheet, the auxiliary electrode is a stainless steel sheet, and the reference electrode is a saturated calomel electrode (SCE);

[0068] 2. The electrolyte solution used in organic coating is composed of the following substances:

[0069]

[0070] 12mmol / L triazazine organic compound salt containing the above-mentioned functional groups, 5mol / L sodium nitrite, and the rest are distilled water;

[0071] 3. The organic coating conditions are as follows:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com