Carburized induction-hardened component

A technology of high-frequency quenching and carburizing, applied in the direction of improving energy efficiency, process efficiency, furnace type, etc., can solve the problems of poor machinability of raw materials and decreased toughness, and achieve small heat treatment deformation, good machinability of raw materials, Effect of High Fatigue Strength and Toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] The present invention is specifically illustrated by the following examples. In addition, these examples are for illustrating the present invention, and do not limit the scope of the present invention.

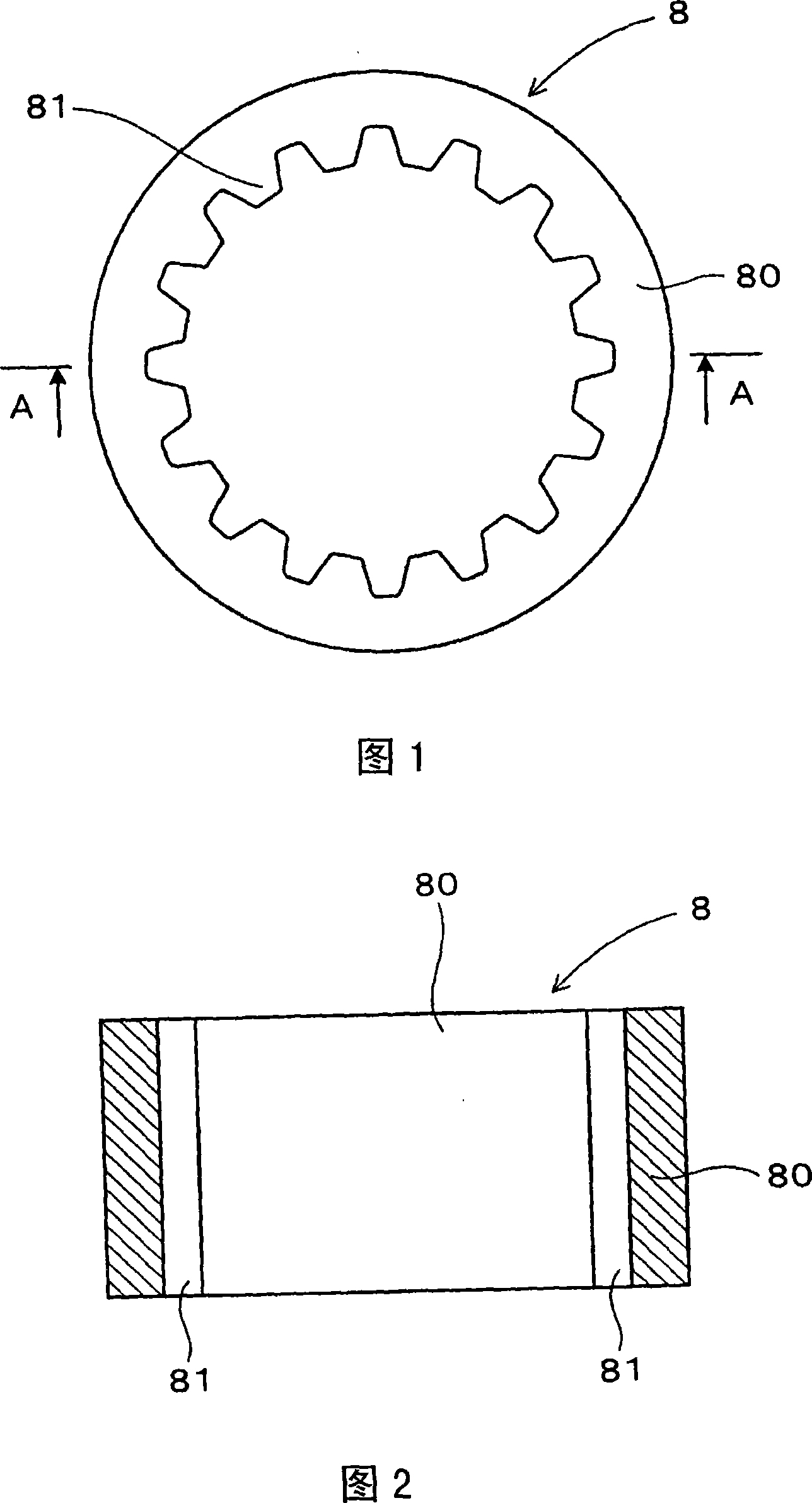

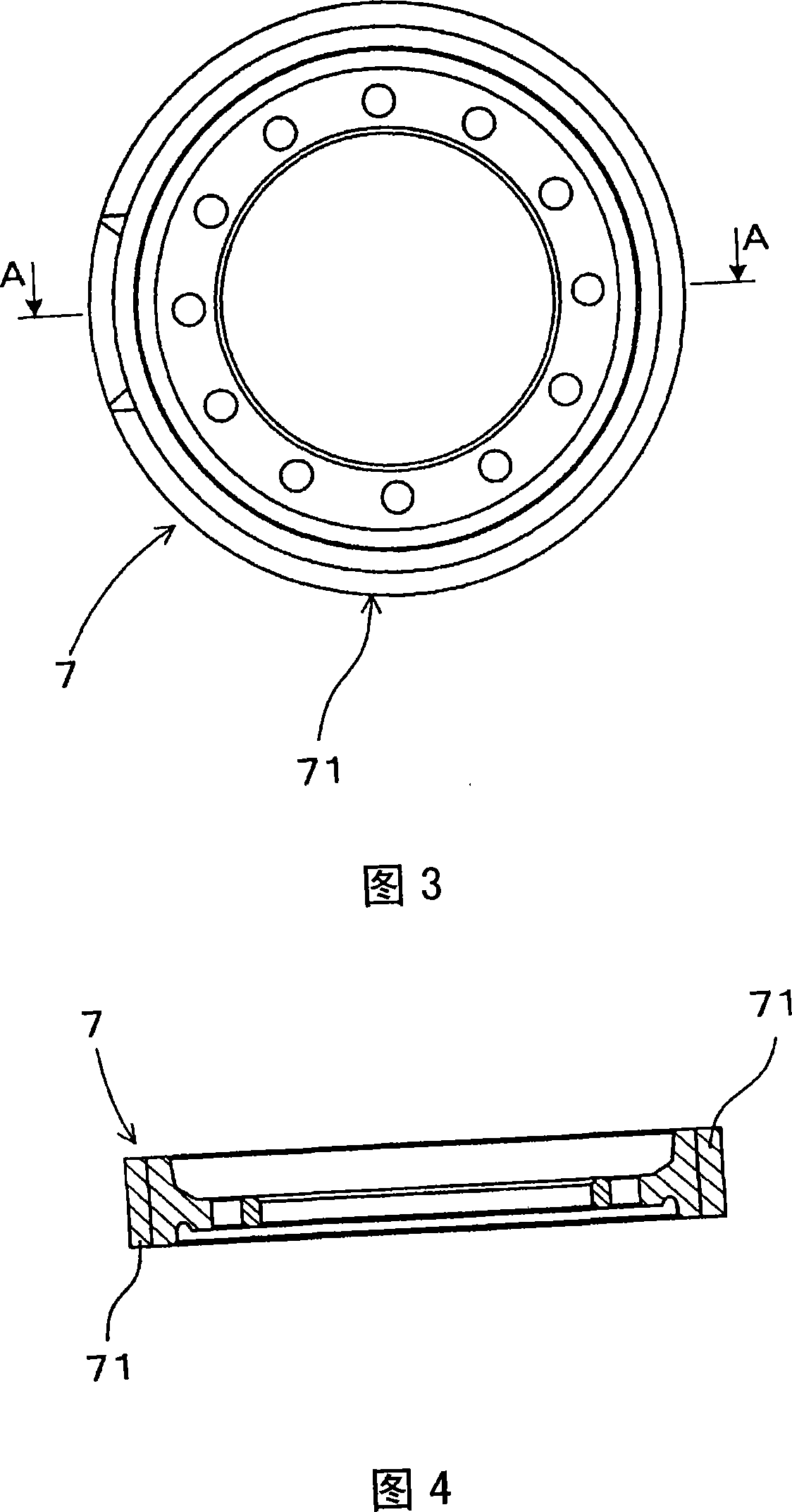

[0112] After the hot-pressed raw materials having the chemical composition shown in Table 1 were hot-forged, they were annealed. Then, by machining, an Ono-type rotating bending fatigue specimen is made, the parallel portion of which is φ9mm, and a semicircular arc with a radius of 1.14mm. Similarly, a U-notch impact test sample (JIS Z 2202, Figure 2a) and a ring gear for gear deformation measurement (pitch circle diameter φ157mm, modulus 2.45, number of teeth 51, inner diameter φ86mm) were produced.

[0113] Next, each sample and the ring gear were processed according to the three manufacturing methods (processes 1-3).

[0114] [Process 1]: Under a reduced-pressure atmosphere of 20hPa, carburizing at 950°C for 30min → slow cooling according to the cooling rate in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shock value | aaaaa | aaaaa |

| Bending fatigue strength | aaaaa | aaaaa |

| Fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com