Exhaust silencing system for static generator set

A generator set, mute technology, applied in the direction of muffler, electrical components, exhaust devices, etc., can solve the problem of limited application scope, and achieve the effect of attenuating propagation, slowing down the rate of change, and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

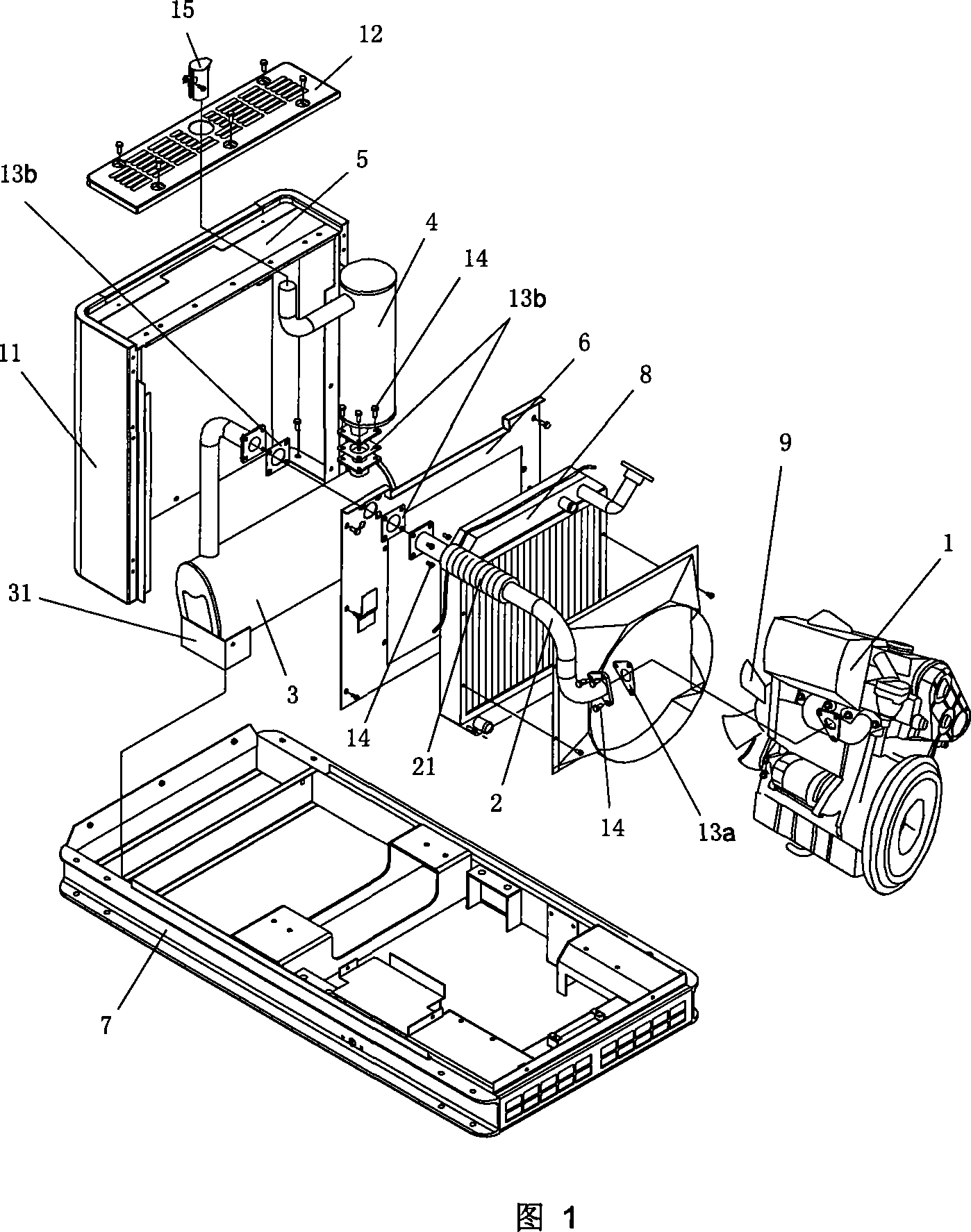

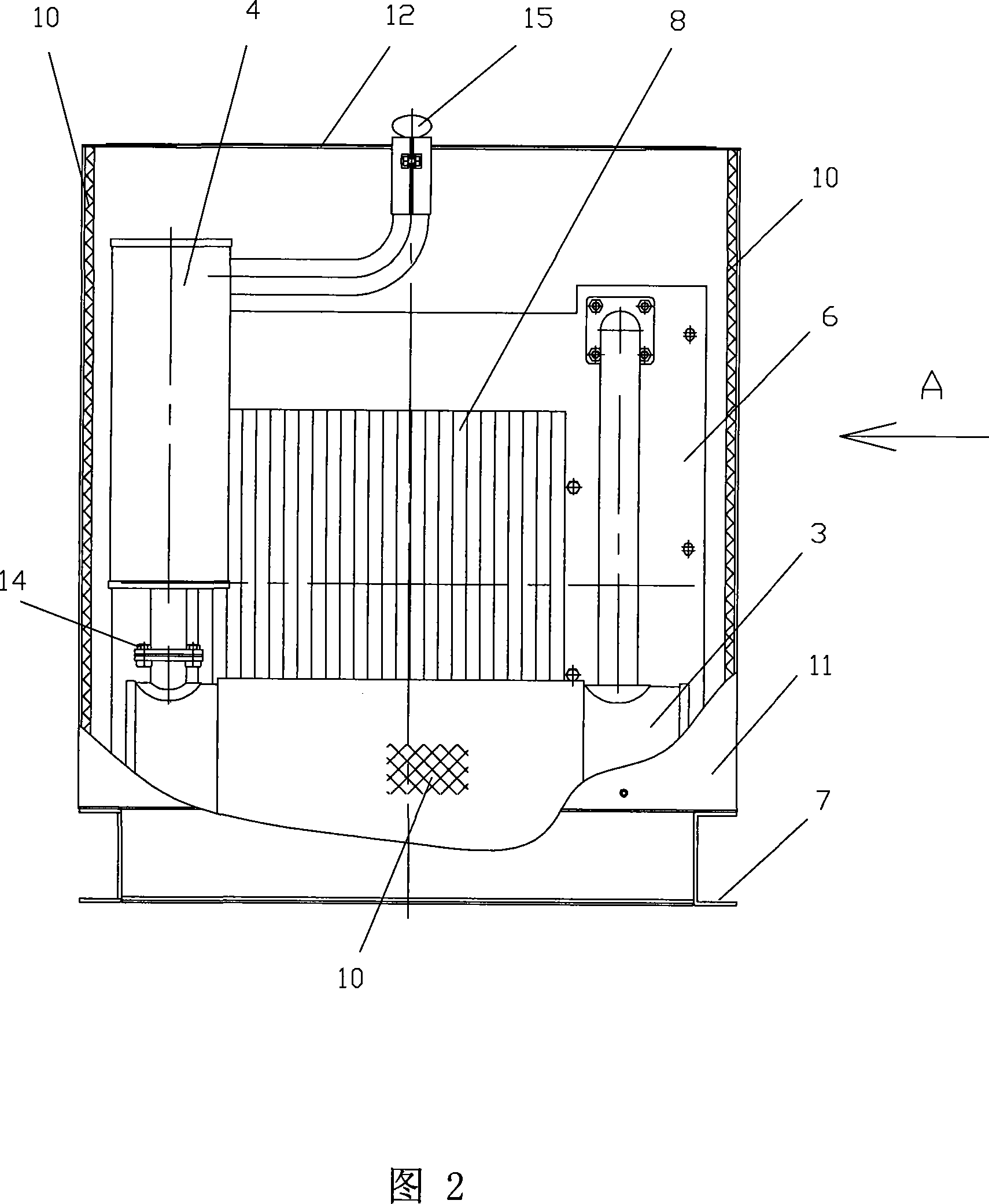

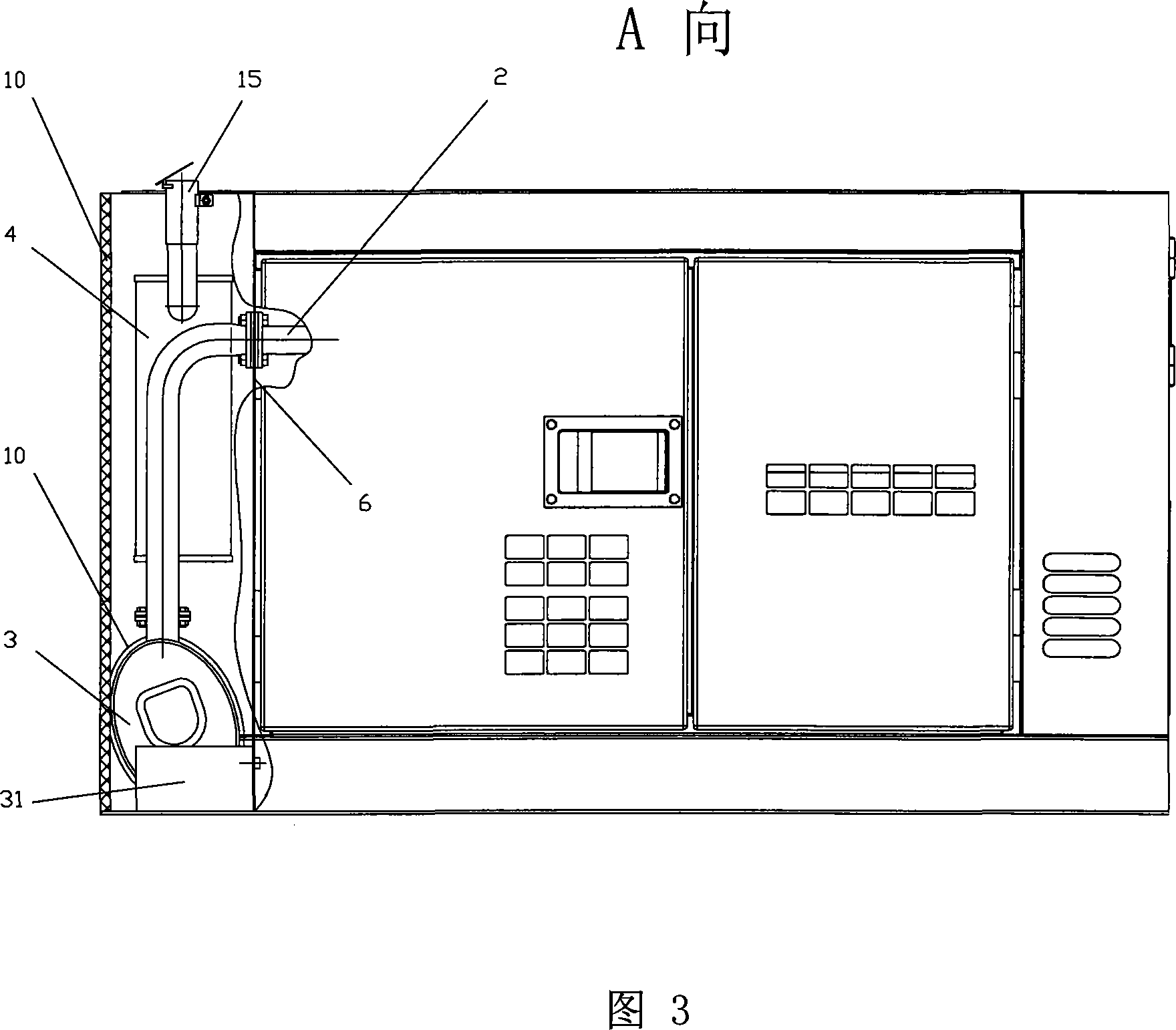

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0019] The present invention mainly consists of engine 1, exhaust pipe 2, flexible pipe section 21, primary muffler 3, support 31, expansion pipe section 32, secondary muffler 4, compartment 5, dividing plate 6, chassis 7, engine radiator 8, fan 9. Sound-absorbing and heat-insulating material 10, rear wall 11, exhaust grille 12, flange gaskets 13a, 13b, bolts 14, exhaust pipe cap 15, etc.

[0020] As shown in Figures 1 to 4: an embodiment of an exhaust muffler system for a silent generator set, including an exhaust pipe 2, a primary muffler 3, a secondary muffler 4, a compartment 5, and sound-absorbing and heat-insulating materials 10, etc. Both the primary muffler 3 and the secondary muffler 4 are arranged in a relatively independent compartment 5, the outlet pipe of the primary muffler 3 is connected to the intake pipe of the secondary muffler 4 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com