Complete balance type high-speed diaphragm compressor capable of realizing monitoring based on industrial internet platform

An industrial Internet, diaphragm compressor technology, applied in the field of diaphragm compressors, can solve the problems that the diaphragm cannot fit with the outer cylinder liner, the compressor loses its working ability, and the clearance volume of the diaphragm cavity is large, so as to increase the overall compactness , The effect of reducing the size of the piston and reducing the volume of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

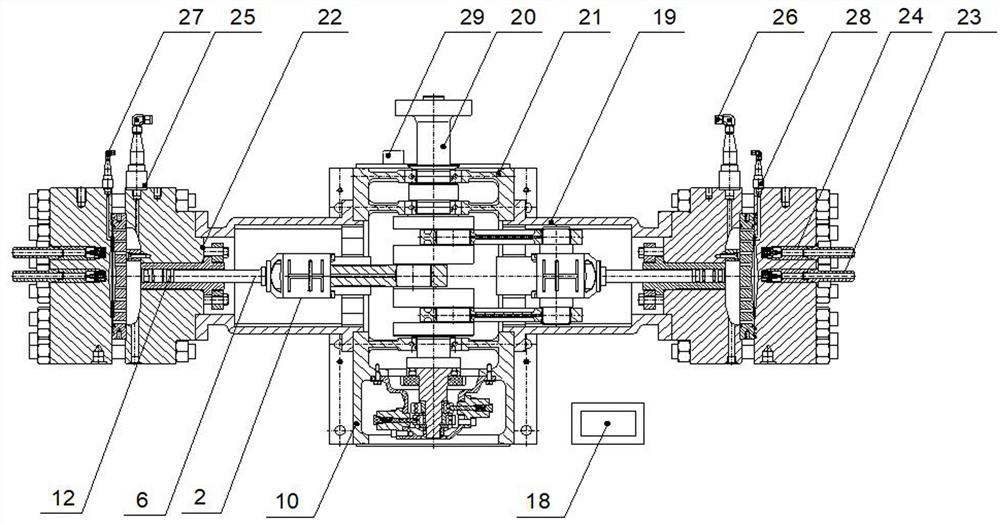

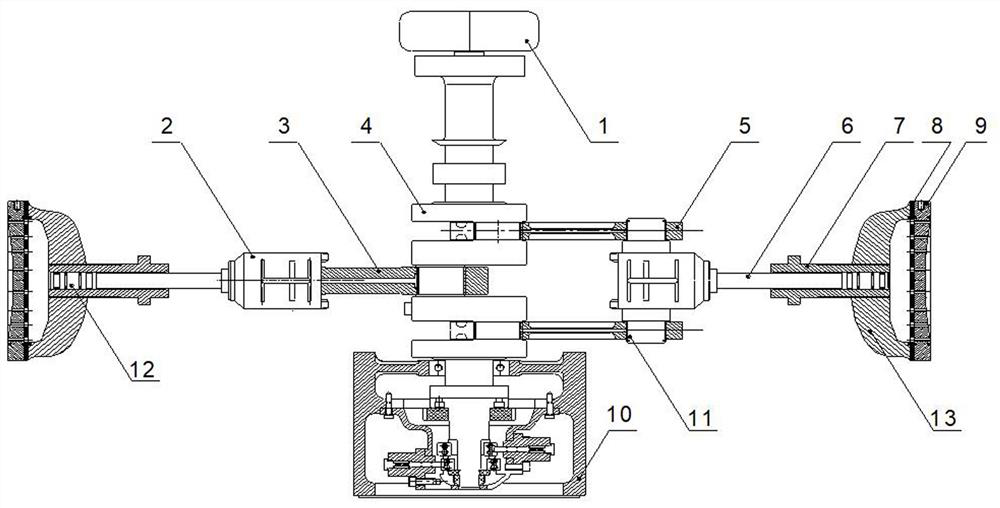

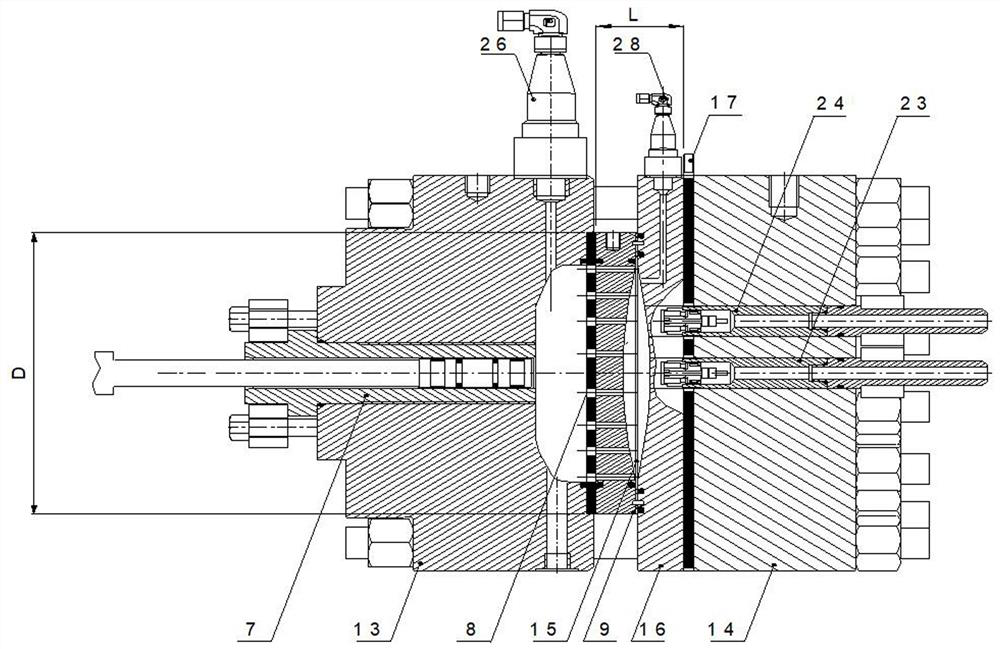

[0031] As shown in the figure, the fully balanced high-speed diaphragm compressor based on the industrial Internet platform for monitoring includes a cylinder part and a transmission part 20; the cylinder part includes two cylinder units 22, and the two cylinder units 22 and The transmission parts 20 are distributed left and right, and are fixed and sealed horizontally by the middle body 19; the cylinder unit includes a pneumatic cylinder head and a hydraulic cylinder head;

[0032] The pneumatic cylinder head includes an outer cylinder liner 16 and a cylinder head 14 fixedly connected; an air suction valve 24 and an exhaust valve 23 are respectively fixed on the cylinder head 14;

[0033] The hydraulic cylinder head includes a fixedly connected cylinder base 13 and an oil distribution plate 9;

[0034] A diaphragm working chamber is formed between the outer cylinder liner 16 and the oil distribution plate 9; the diaphragm group 15 is horizontally arranged in the diaphragm wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com