Split type internal combustion engine

A split type internal combustion engine and compressor technology, which is applied in the direction of combustion engines, mechanical equipment, machines/engines, etc., can solve the problems of high intake temperature of internal combustion engines, insufficient fuel combustion, low fuel utilization rate, etc., and achieve high compression efficiency, The effect of sufficient combustion and high fuel utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

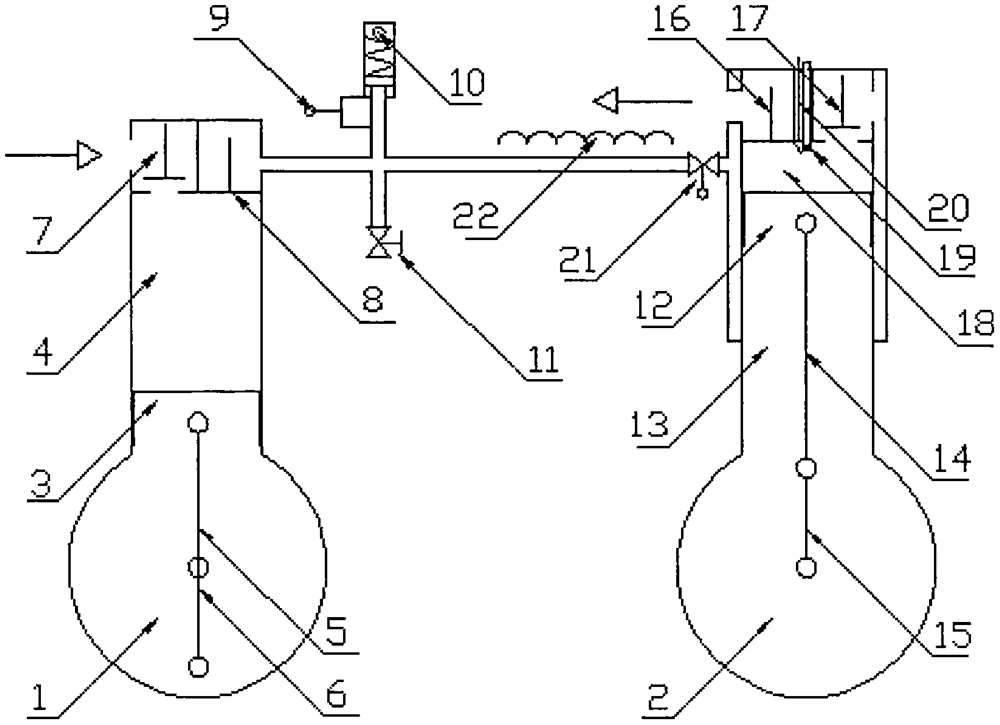

[0008] As shown in the accompanying drawings, the split type internal combustion engine is composed of two independent systems of a compressor 1 and an engine 2 .

[0009] The compressor is composed of piston 3, cylinder 4, connecting rod 5, crankshaft 6, intake valve 7, exhaust valve 8, pressure controller 9, safety valve 10, backup valve 11 and so on. The piston reciprocates once up and down in the cylinder to complete a working cycle consisting of intake and compression strokes.

[0010] At the beginning of the intake stroke of the compressor, the piston is at the top dead center. Since there is no combustion chamber, the volume above the piston in the cylinder approaches zero, and there is no exhaust gas. When the crankshaft rotates, the connecting rod moves the piston from the top dead center to the bottom dead center, and at the same time, the intake valve of the compressor opens. With the downward movement of the piston, the volume above the piston in the cylinder incre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com