Environment-friendly type composite pre-film reagent used for recirculated cooling water system pre-film processing and method of use thereof

A technology of circulating cooling water and pre-filming agent, applied in water/sludge/sewage treatment, chemical instruments and methods, descaling and water softening, etc. The effect of good corrosion resistance, saving replacement water and fast film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation process: prepare 100.00g each of environment-friendly composite pre-film agent A and B

[0039] Preparation of agent A: 65.00g of 2-phosphonic acid group-1,2,4-tricarboxylic acid butane (PBTCA) with a solid content of 50% and 4.80g of acrylic acid / 2-methyl-butane with a solid content of 30% Mix and stir 2'-acrylamidopropanesulfonic acid binary copolymer (AA / AMPS) and 19.20 g of water evenly, then add 11.00 g of zinc sulfate heptahydrate and stir to dissolve, and obtain 100.00 g of the required A agent.

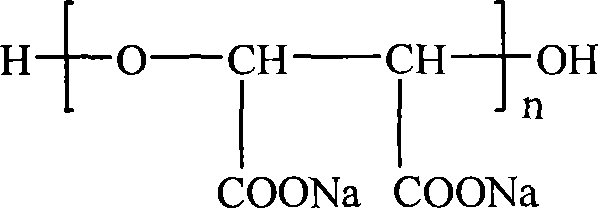

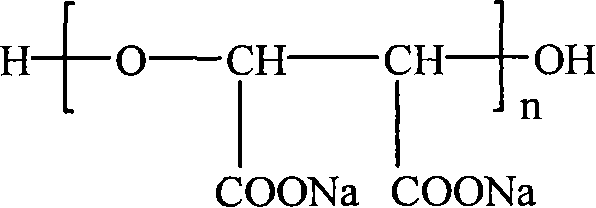

[0040] The preparation of agent B: be that 31.2g solid content is 40% sodium polyepoxysuccinate and 63.3g water mix and stir evenly, add the benzotriazole of 2.5g and 3.0g sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) Stir and dissolve to obtain the 100g B agent that needs to be prepared.

[0041] Add agent A and agent B of the above prepared agent solution directly to the experimental water in the ratio of weight ratio A:B=1:1 to carry out the rotary ha...

Embodiment 2

[0051] Preparation process: prepare 100.00g each of environment-friendly composite pre-film agent A and B

[0052] Preparation of Agent A: 66.60g solid content of 2-phosphonic acid group-1,2,4-tricarboxylic acid butane (PBTCA), 2.70g solid content of 30% acrylic acid / 2-methyl- Mix and stir 2'-acrylamidopropanesulfonic acid binary copolymer (AA / AMPS) and 18.70 g of water evenly, then add 12.00 g of zinc sulfate heptahydrate and stir to dissolve, and obtain 100.00 g of the required A agent.

[0053] Preparation of agent B: 50.00g solid content is 40% sodium polyepoxysuccinate mixed with 16.0g water and stirred evenly, then add 2.00g of benzotriazole and 4.00g of sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) Stir and dissolve to obtain the 100g B agent that needs to be prepared.

[0054]Add agent A and agent B of the above prepared agent solution directly to the test water in the ratio of weight ratio A:B=1:1 to carry out the rotating test, and add 150mg L of agent A -1 , do...

Embodiment 3

[0064] Preparation process: prepare 100.00g each of environment-friendly composite pre-film agent A and B

[0065] Preparation of agent A: 60.00g of 2-phosphonic acid group-1,2,4-tricarboxylic acid butane (PBTCA) with a solid content of 50% and 3.60g of acrylic acid / 2-methyl-butane with a solid content of 30% Mix and stir 2'-acrylamidopropanesulfonic acid binary copolymer (AA / AMPS) and 19.60 g of water evenly, then add 16.80 g of zinc sulfate heptahydrate and stir to dissolve, and obtain 100.00 g of the required A agent.

[0066] The preparation of agent B: 31.20g solid content is 40% sodium polyepoxysuccinate and 64.50g water mix and stir, then add 2.00g of benzotriazole and 2.30g of sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) Stir and dissolve to obtain 100.00g of B agent to be prepared.

[0067] Add agent A and agent B of the above prepared agent solution directly to the experimental water in the ratio of weight ratio A:B=1:1 to carry out the rotary hanging test, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com