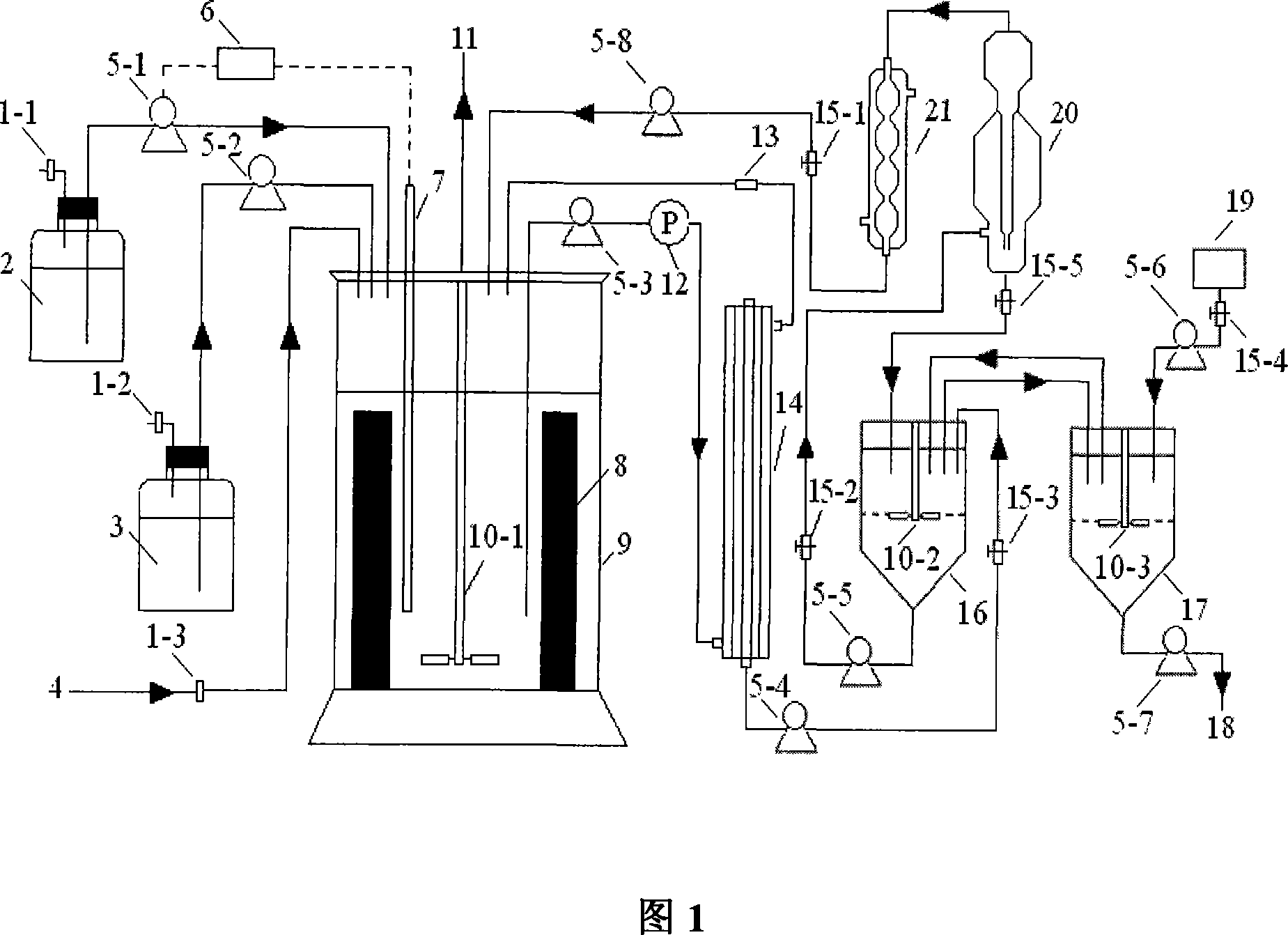

Device and technique for producing propanoic acid by coupling of fibrous bed bioreactor with extraction separation

A technology of reactor and fiber bed, which is applied in the field of equipment for producing propionic acid coupled with fiber bed reactor and extraction separation, can solve the problems of slow growth of propionic acid production, achieve the elimination of feedback inhibition, improve extraction efficiency, equipment and process operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Propionibacterium freudeenreichii NX-4 (Propionibacterium freudeenreichii NX-4, patent number: 200710020579.8, published on October 3, 2007) seed solution with 5% (v / v) inoculation amount Inoculate in the reactor 9 pre-filled with 3L seed medium, the temperature is 30°C, and 0.05L / min N is passed through the inert gas inlet 4 2 At the same time, the constant flow pump 5-1 was used to add 8 mol / l sodium hydroxide aqueous solution to the reactor 9 to control the pH 6.0, and the static culture was carried out for 48 hours to realize the adsorption and fixation of the bacterial strain on the plant fiber (gauze) 8. Replace the seed liquid in the reactor 9 with the fermentation medium, the initial pH is 6.9, use the constant flow pump 5-1 to add 8 mol / l sodium hydroxide aqueous solution to the reactor 9 to control the pH 6.0, and the initial glucose concentration is 50g / l That is, glucose is added to the fermentation medium, and 0.1L / min N 2 , culture temperature 30 ℃, stati...

Embodiment 2

[0045] Insert the P. frescheri NX-4 seed liquid into the reactor 9 pre-installed with 3L seed culture medium with an inoculum size of 10% (v / v), at a temperature of 35° C., feed 0.2 L / min N 2 , use the stirring device 10-1 to stir (rotating speed 200r / min), and use the constant flow pump 5-1 to add 3mol / l sodium hydroxide aqueous solution to control pH 6.0 at the same time, cultivate 36h to realize the cells on the plant fiber 8 (cotton cloth) fixed. Replace the seed liquid in the reactor 9 with the fermentation medium, the initial pH is 6.9, and at the same time use the constant flow pump 5-1 to add 3 mol / l sodium hydroxide aqueous solution to control the pH 6.0, the initial glucose concentration is 120g / l, and the temperature is 35°C , into 0.2L / min N 2 , using the stirring device 10-1 to stir (rotating speed 200r / min), ferment for 150h, the output of propionic acid is 57.5g / l, and the production efficiency reaches 0.38g / l / h.

Embodiment 3

[0047] Insert the P. freudenii NX-4 seed liquid into the reactor 9 pre-installed with 3L seed medium with an inoculum size of 15% (v / v), at a temperature of 37°C, feed 0.3L from the inert gas inlet 4 / min N 2 , using the stirring device 10-1 to stir (rotating speed 400r / min), while using the constant flow pump 5-1 to add 5mol / l sodium bicarbonate aqueous solution to the reactor 9 to control the pH 6.0, and cultivate for 30h to realize the cells in the animal fiber ( Wool fabric) 8 fastening. The seed liquid in the reactor 9 is replaced by the fermentation medium, and the initial pH is 6.9, and at the same time, the constant flow pump 5-1 is used to add 5 mol / l sodium bicarbonate aqueous solution to control the pH 6.0, and the initial glucose concentration is 80g / l. Gas inlet 4 into 0.1L / min N 2 , using the stirring device 10-1 to stir (rotating speed 400r / min), after cultivating for 80h, the fermentation liquid is pumped into the membrane module 14 (alumina inorganic ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com