Method for preparing glaze ceramic wine bottle with body-hidden bottom

A ceramic wine bottle and color glaze technology, applied in clay products, other household utensils, household utensils and other directions, can solve problems such as scratching the table top, affecting the quality of the glaze surface, affecting the quality of the glaze surface of the bottom glaze, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

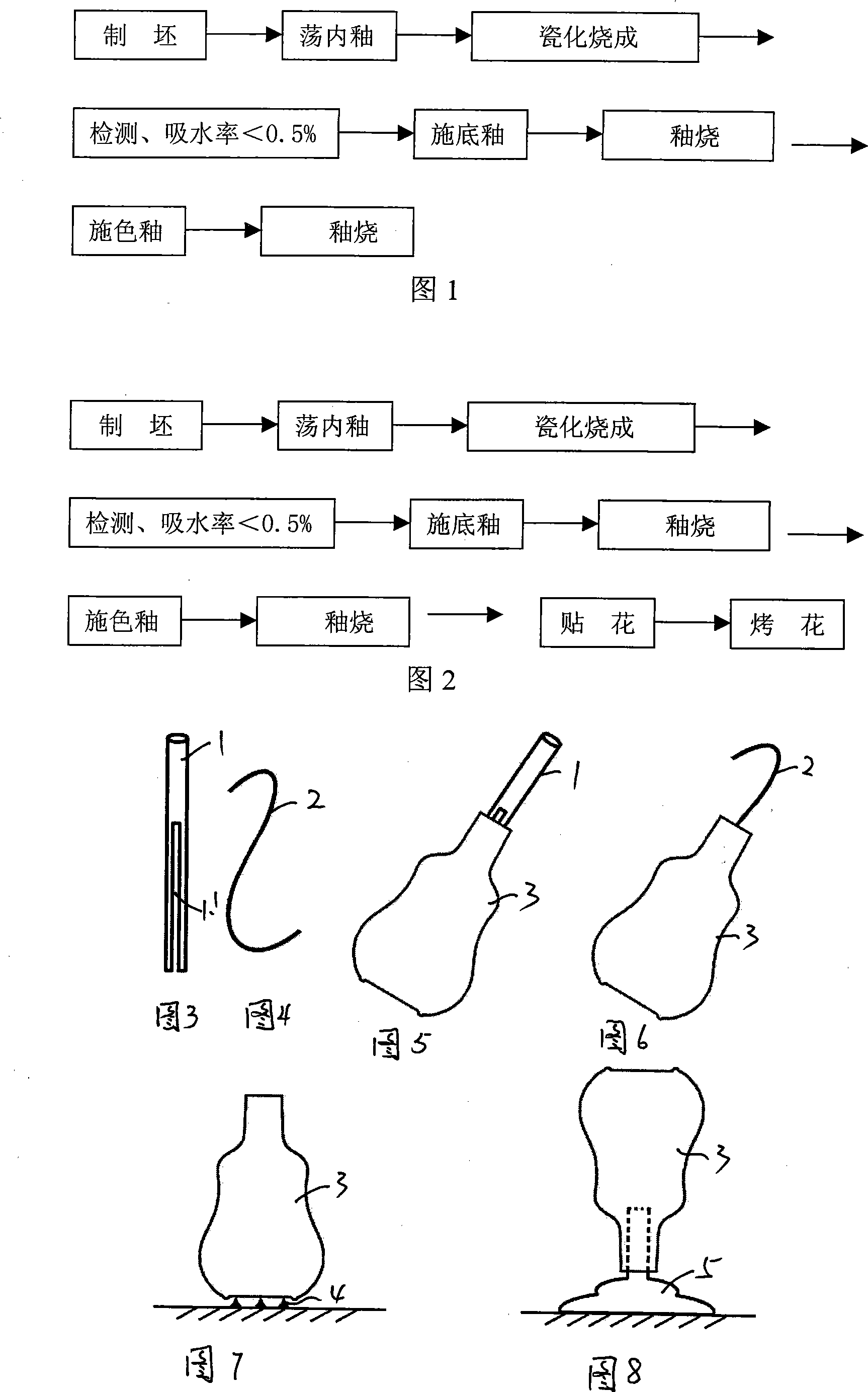

[0023] Embodiment 1: referring to Fig. 1, 7, 8, the preparation method of the color glazed ceramic wine bottle of the present invention with bottom foot not exposed tire, in various regular or irregular wine bottle 3 green bodies after drying, applies high temperature inner glaze (not Apply any outer glaze) and fire at a high temperature of 1180-1300°C until the water absorption rate of the product is ≤0.5%. Prepare a glossy bottom glaze that is 100-130°C lower than the first firing temperature and has a glaze slurry concentration of 56-68°Be. To improve the glaze performance, you can add an appropriate amount of suspending agent and adhesive (commercially available) to the glaze slurry. , use methods such as dipping or spraying glaze to apply glossy bottom glaze on the outer surface of the fired porcelain wine bottle, do not rub enough, after drying, use refractory triangular nails 4 to support the kiln (Figure 7), and glaze firing at 1050-1200 °C. Grinding the nail scars to ...

Embodiment 2

[0025] Embodiment 2: referring to Fig. 2, as mentioned above, the red glaze ceramic wine bottle of above-mentioned burning bottom foot is not exposed tire, the surface is carried out decal or hand-painted decoration, press firing red glaze temperature or be lower than color glaze temperature (that is not Exceeding the color glaze temperature (for example, 480-680 ℃) hanging or the mouth of the bottle is inserted into the supporting kiln furniture and baked upside down (roasted flowers), that is, the finished red glaze ceramic wine bottle with no exposed bottom and decorated surface.

[0026] In addition, it is also possible to apply the inner glaze and the glossy bottom glaze separately, fire it once for porcelain, and then apply the red glaze and glaze firing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com