glass column

A glass column and component technology, applied in decorative arts, special decorative structures, building types, etc., can solve problems such as unevenness or even cracking, inaccurate ordering of metal clips, and easy loosening of glass columns, so as to improve the quality of decoration. , Improve the construction efficiency and eliminate the effect of quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

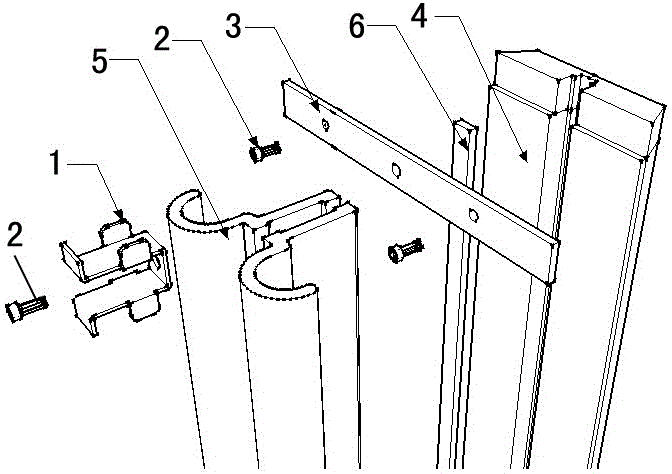

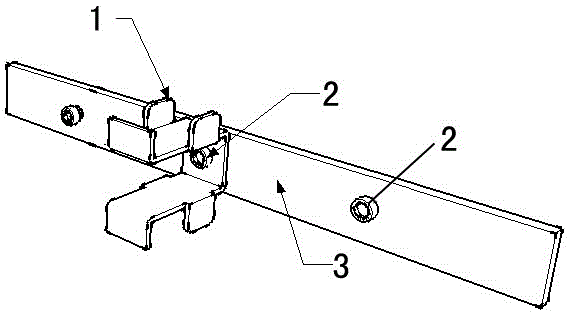

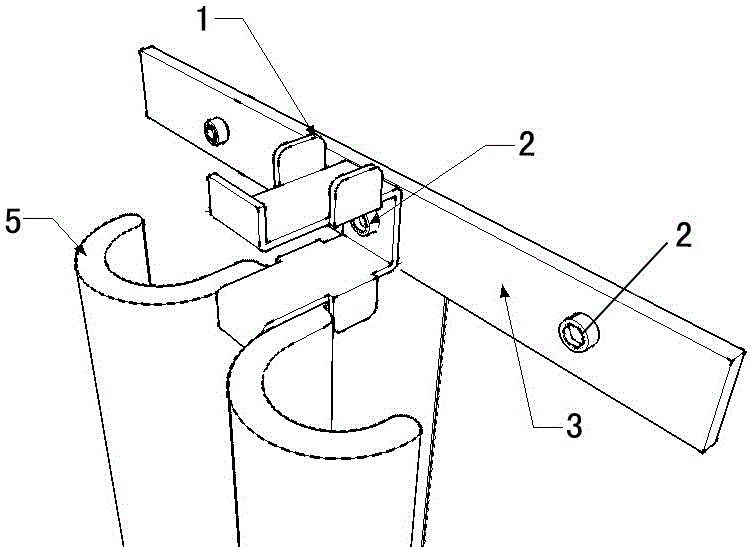

[0023] Example: such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a glass column includes a metal clip 1 , a metal decorative strip 3 , a wood veneer 4 , a glass column assembly 5 , and a light strip 6 .

[0024] Each glass column assembly 5 is composed of two glass column units combined. The glass column unit has a semi-cylindrical appearance part and a mounting part extending to the back. The installation parts of the two glass column units are combined to form the installation of the glass column assembly 5 Fixing part, the upper end of the fixing part of each glass column assembly 5 is fixed by a metal clip 1, and the lower end is fixed by another metal clip 1; the upper part of each metal clip 1 is fixed to a glass column assembly 5, and the lower part is fixed to another A glass column assembly5.

[0025] The main body section of the metal clip 1 is in a horizontal U-shape, including upper and lower parts, the upper part is provided with a slot structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com