Air dryer suitable for use in dusty environment

An air dryer and environmental technology, applied in applications, refrigerators, household heating and other directions, can solve the problems of large baking and drying pollution, large drying energy consumption, increased cost, etc., to improve dehumidification efficiency, ensure effective heat dissipation, Easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

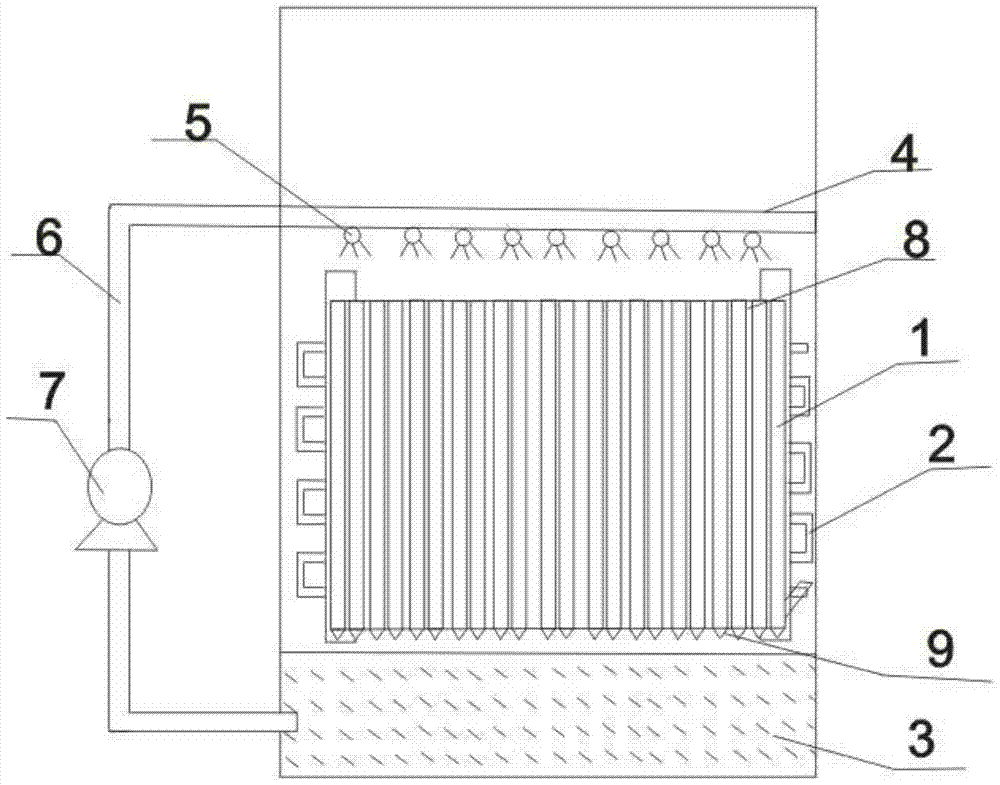

[0041] Example 1, as Figure 1-5 As shown, the air dryer of the present invention suitable for use in a dusty environment includes an evaporator 1 arranged on one side of the air suction port, a condenser 2 arranged side by side with the evaporator 1, and the evaporator 1 and the condenser 2. The water tank 3 below is used to store the condensed water. The air dryer also includes a case, a compressor, a fan, etc., which are the prior art and will not be repeated here. In the present invention, the air inlet is located on the front side of the case, and the air outlet is located in the The position near the rear, this is a conventional design, not shown in the picture.

[0042]Evaporator 1 consists of vertical pipes, the vertical pipes of evaporator 1 are arranged in a spiral, like a horizontally placed columnar spring, and the side of the spiral vertical pipes of evaporator 1 is away from the air intake. A whole piece of heat sink 8 is provided. A triangular drip block 9 is ...

Embodiment 2

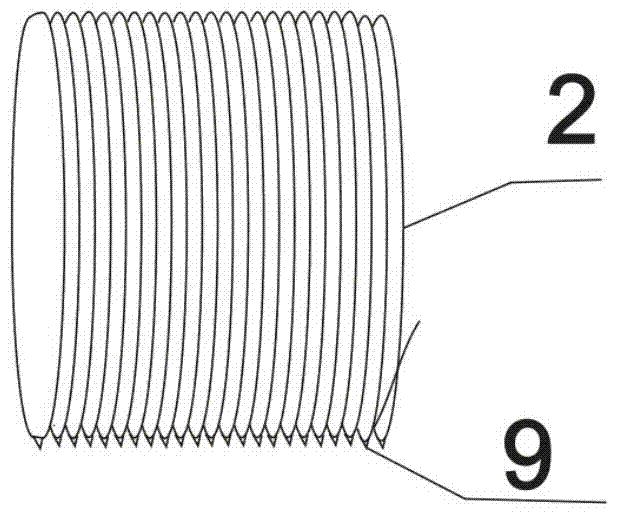

[0046] like Figure 6-8 Shown: other structures are the same as in Example 1, the difference is that the condenser 2 and the evaporator 1 have the same structure, the condenser 2 is also composed of vertical pipes, and the vertical pipes of the condenser 2 are also spiral tight arrangement. Only the pipe diameter of the vertical exhaust pipe of the condenser 2 is smaller than the pipe diameter of the vertical exhaust pipe of the evaporator 1 . A triangular drip block 9 is provided on the tube wall of the bottom end of the vertical pipe of the evaporator 1 . A whole piece of radiating fins 8 is also provided on one side of the spiral vertical pipe of the condenser 2 .

Embodiment 3

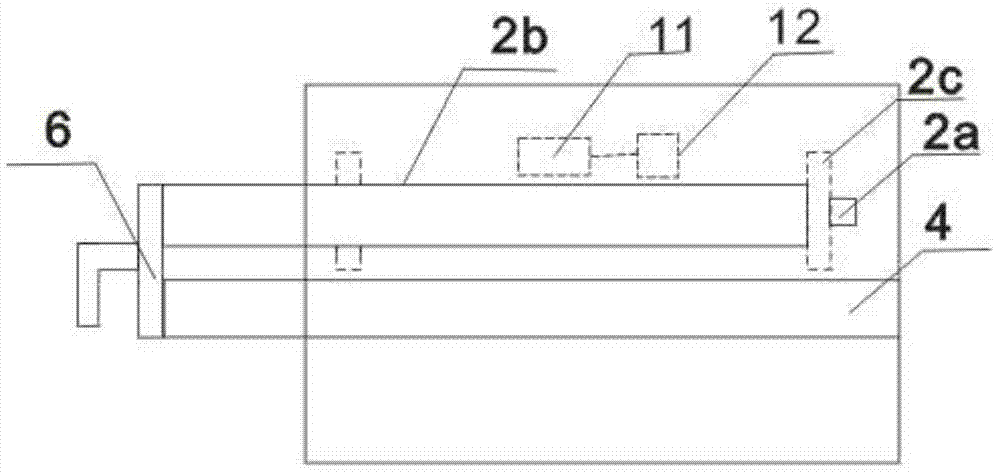

[0048] like Figure 9-10 As shown: other structures are the same as in Embodiment 1, the difference is that the condenser 2 includes mounting plates 2c at both ends, and two rows of transverse coils 2a are arranged between the mounting plates 2c at both ends. The heights of the coils 2a are arranged at different heights.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com