Image characteristic extracting method of structure light straight-line striation of three steps method

A technology of image characteristics and three-step method, which is applied in the directions of image analysis, image data processing, and optical device, can solve the problems of low efficiency, difficult to fully utilize, complicated operation, etc., achieve high degree of automation, easy operation, and improve on-site The effect of ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

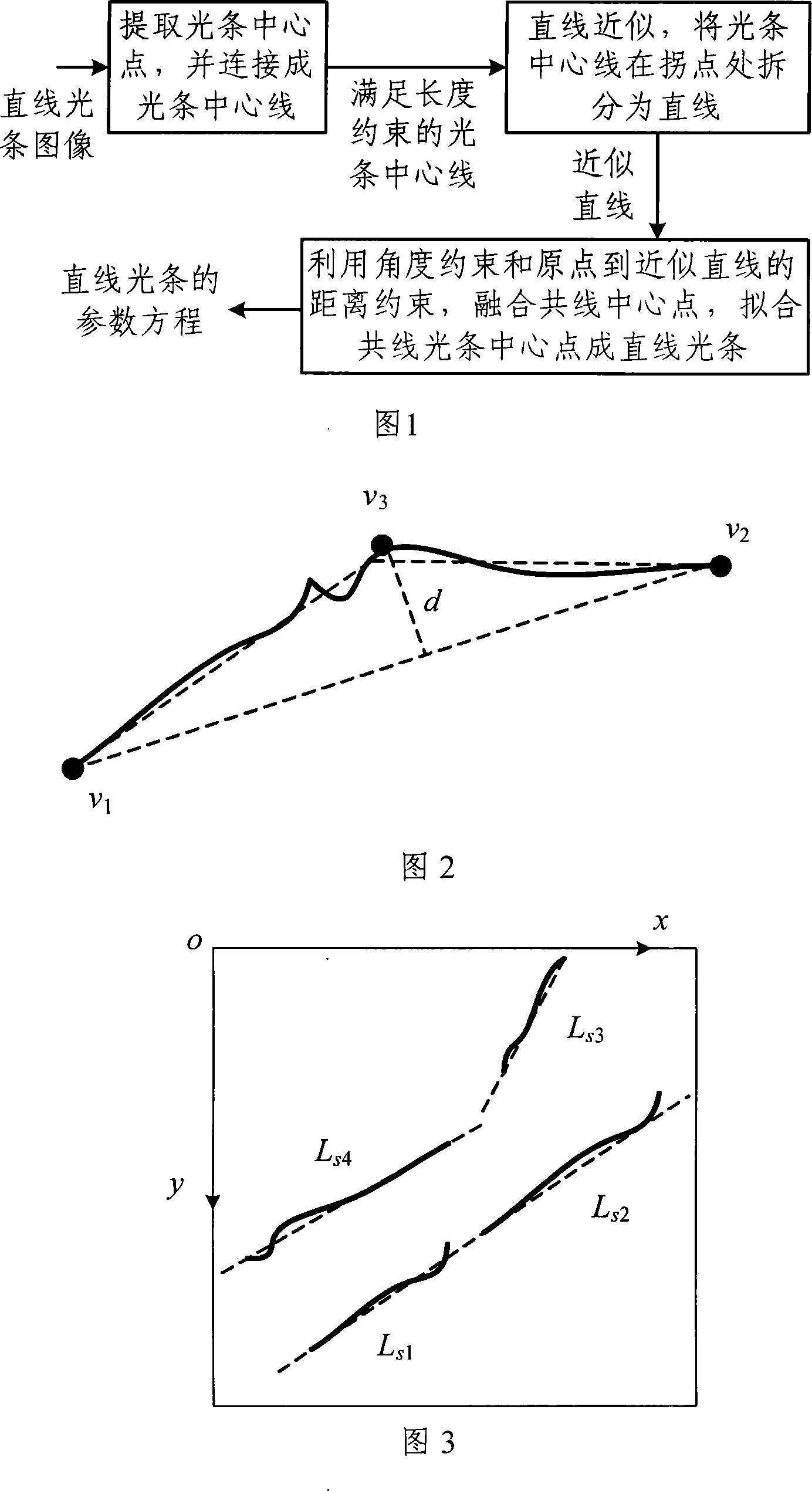

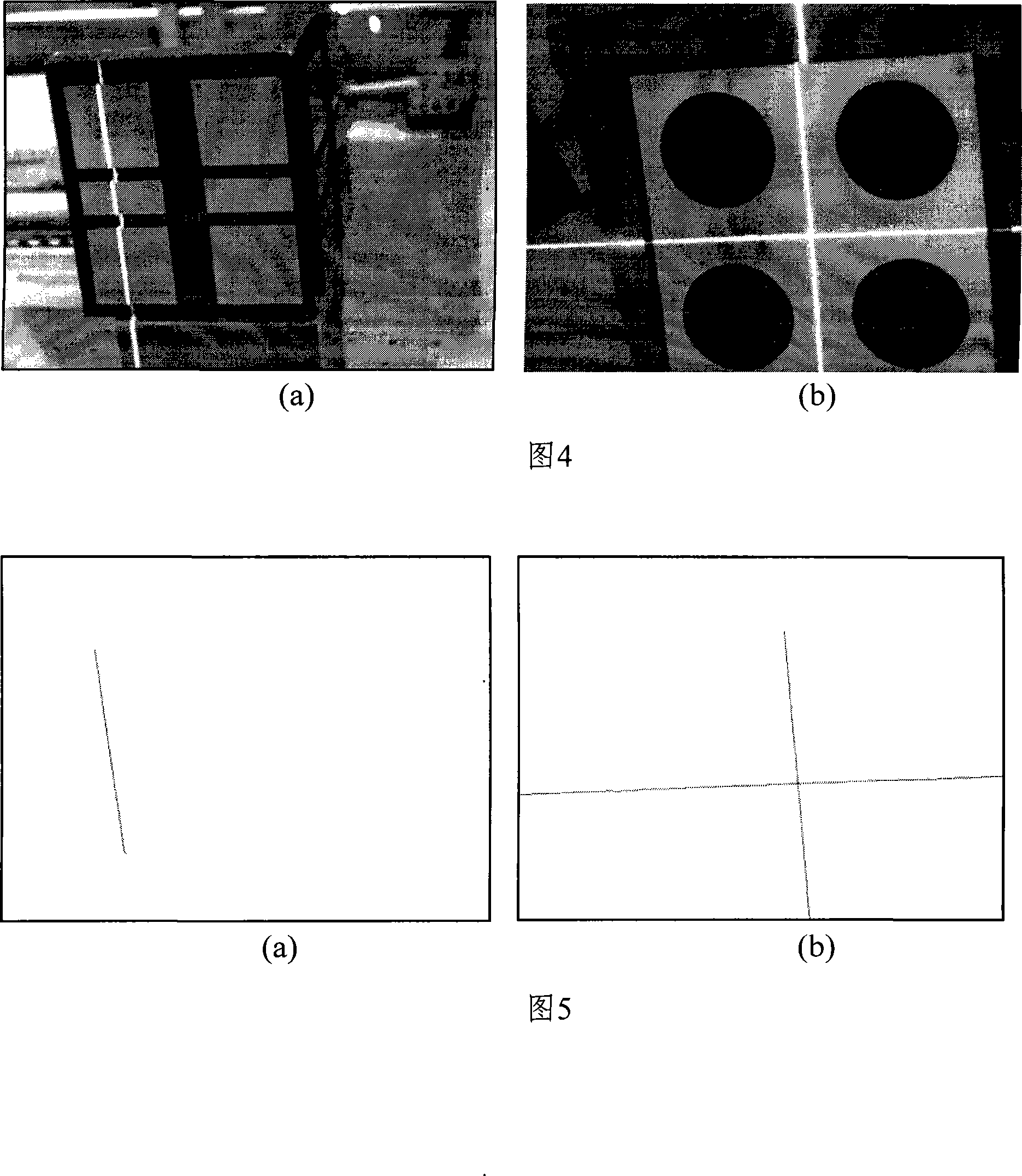

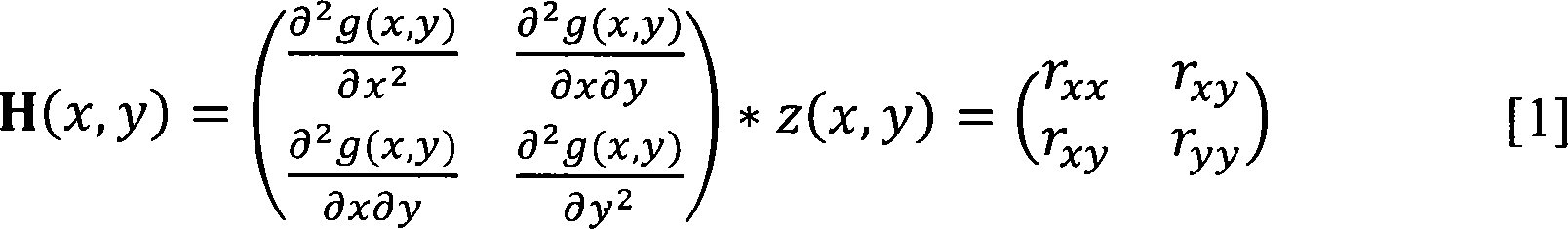

[0057] The process flow of the image feature automatic extraction method of the three-step linear light strip is shown in Figure 1. Taking the linear light bar in the parameter calibration of the line structured light vision sensor as an example, the experiment is carried out. The plane structured light projected by the line structured light projector intersects with the calibration target plane to form a straight light strip. Since the target plane contains other physical features, such as round holes, black and white squares, etc., the structured light strip image captured by the camera, its Characteristic representation of non-completely rectilinear light streaks in complex backgrounds. Figure 4(a) and Figure 4(b) are the images of a single straight line light strip and a cross line light strip image respectively, and the image resolution is 768×576 pixels. According to the three-step linear light strip extraction method proposed by the present invention, straight line ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com