Optical thin sheet with reinforced structur

A technology of optical flakes and structures, applied in optics, nonlinear optics, coatings, etc., can solve the problems of poor light transmittance and defect rate of glass substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

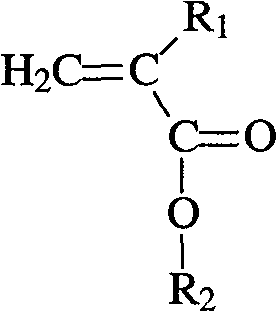

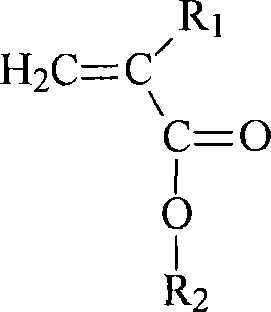

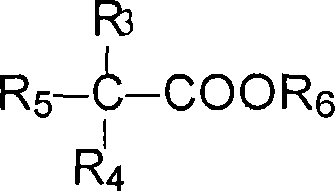

Method used

Image

Examples

preparation example 1

[0064] The polyacrylate resin of Example 1 was prepared with monomers, solvents and appropriate initiators in different proportions, and the preparation conditions are shown in Table 1:

[0065] Table 1

[0066] mixture

[0067] Initiator (AIBN)

Embodiment 1

[0069] The polyacrylate resin prepared above is reacted with a hardener and other solvents to prepare the thermosetting resin of the protective layer of the present invention. The preparation conditions are shown in Table 2:

[0070] Table 2

[0071] raw material

preparation example 2-3

[0073] The fluorocarbon resin of Example 2 was prepared with different ratios of monomers, solvents, and appropriate initiators. The preparation conditions are shown in Table 3:

[0074] table 3

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com