Conical reflecting mirror and device using same

A reflective mirror and cone-shaped technology, applied in the field of reflective mirrors, can solve problems such as complex design of level gauges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

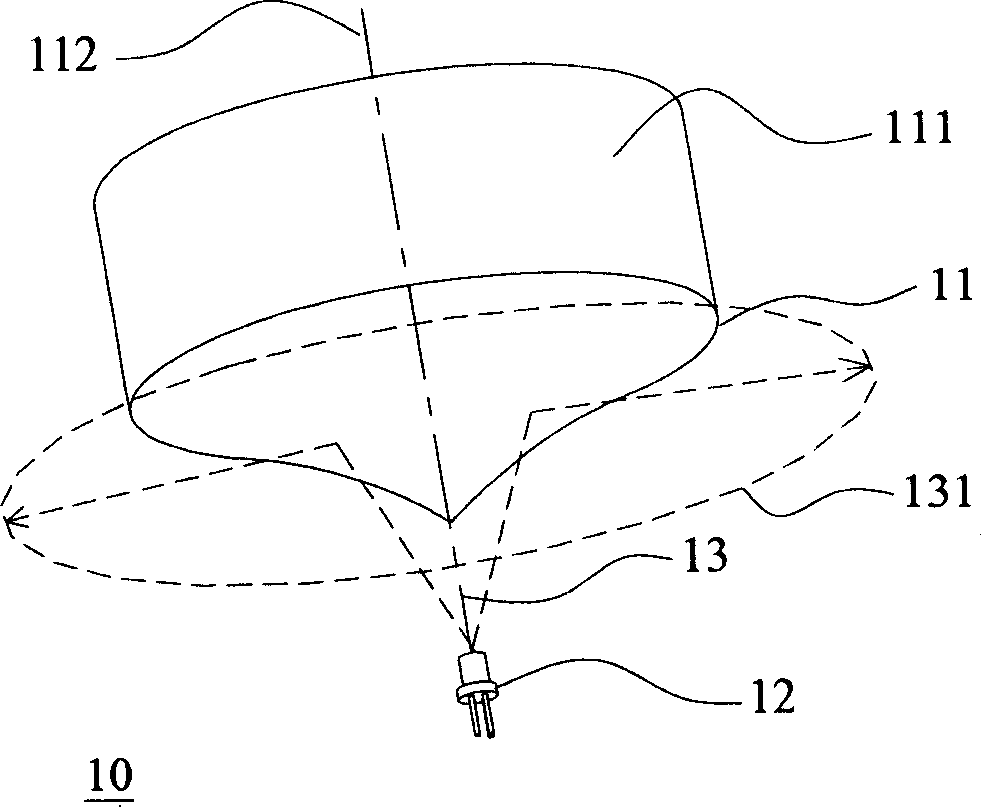

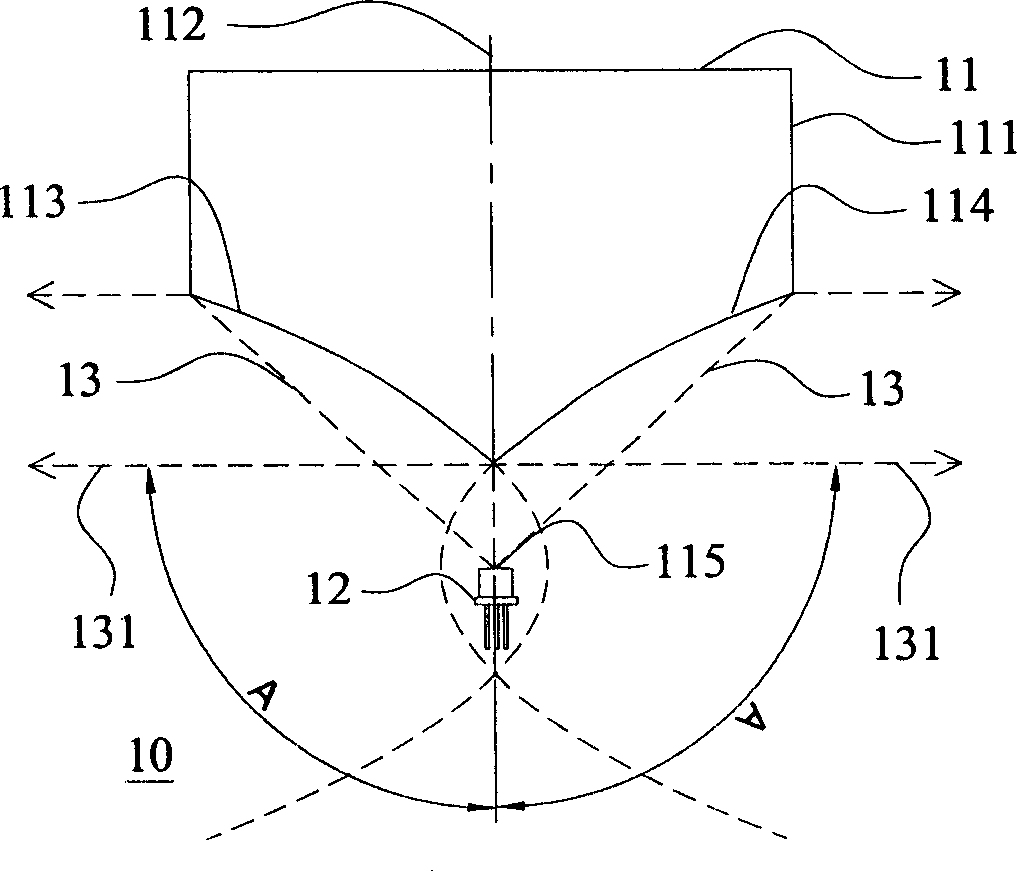

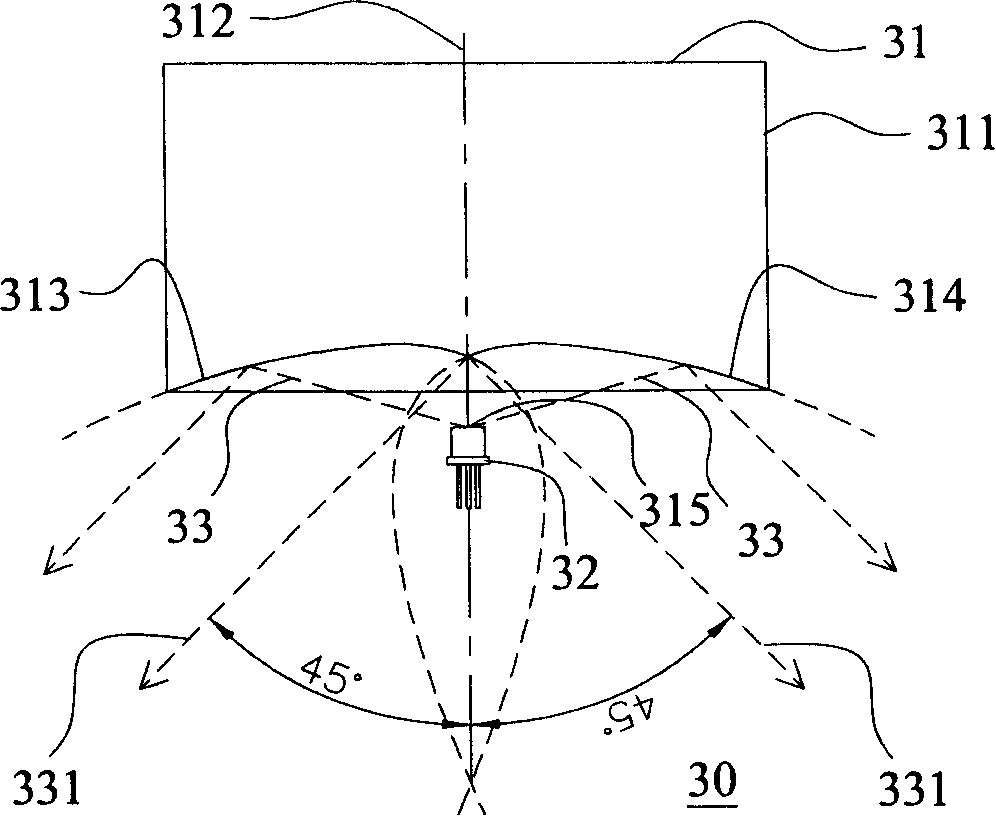

[0015] Please refer to figure 1 and figure 2 As shown, they are respectively a perspective view and a schematic cross-sectional view of a tapered reflector application device according to the first embodiment of the present invention. In the figure, the application device 10 includes a conical reflector 11 and a light source 12 such as a laser diode, wherein the light source 12 does not need to use a collimating lens except for the laser diode, so that the laser beam generated by the laser diode 13. Collimated into parallel laser beams. In addition, when the light source 12 is a diode-pumped solid-state laser (DPSS for short) such as a green laser, the collimator lens in the beam expander can also be omitted, so that the light source 12 produces a diverging laser beam 13.

[0016] The conical reflector 11 is preferably a cylindrical body 111, the central position of the cylindrical body 111 has a reference longitudinal axis 112, and any section around the longitudinal axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com