Mine water down-hole treatment system

A treatment system, mine water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve equipment corrosion, power equipment and pipeline investment, and price Expensive and other issues, to achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

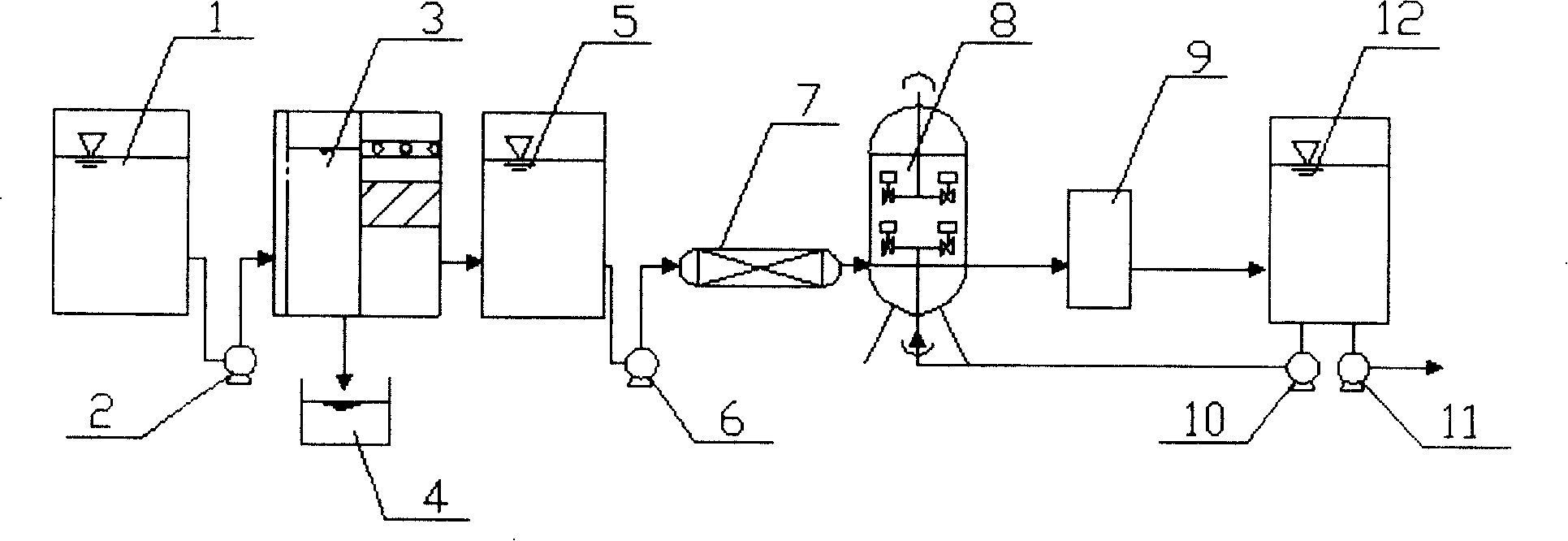

[0017] The present invention aims at the present situation that the current mine water treatment equipments are all concentrated on the ground, occupying a large area, and the transportation distance of water treatment and reuse is long, and develops an underground mine water treatment system. System, filtration system, antiscaling system, water supply system. Mine water is first precipitated by the sedimentation system, then filtered by the filtration system, and finally purified by the antiscalation system to obtain clean water that can be reused. The water supply system includes multiple water pumps.

[0018] Its preferred implementation is as figure 1 As shown, the system includes a sedimentation tank 3, a two-stage filtration system 7, 8, a scale inhibitor 9, multiple water pumps, a backwashing device and a control system (not shown in the figure).

[0019] The raw water of the mine water enters the sedimentation tank 3 from the underground water tank 1 through the lift p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com