Ordered meso-porous silicon oxide material

A silicon oxide and double mesoporous technology, applied in the direction of silicon oxide, etc., can solve the problems of no creation, no ordered double mesoporous, etc., and achieve the effect of high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

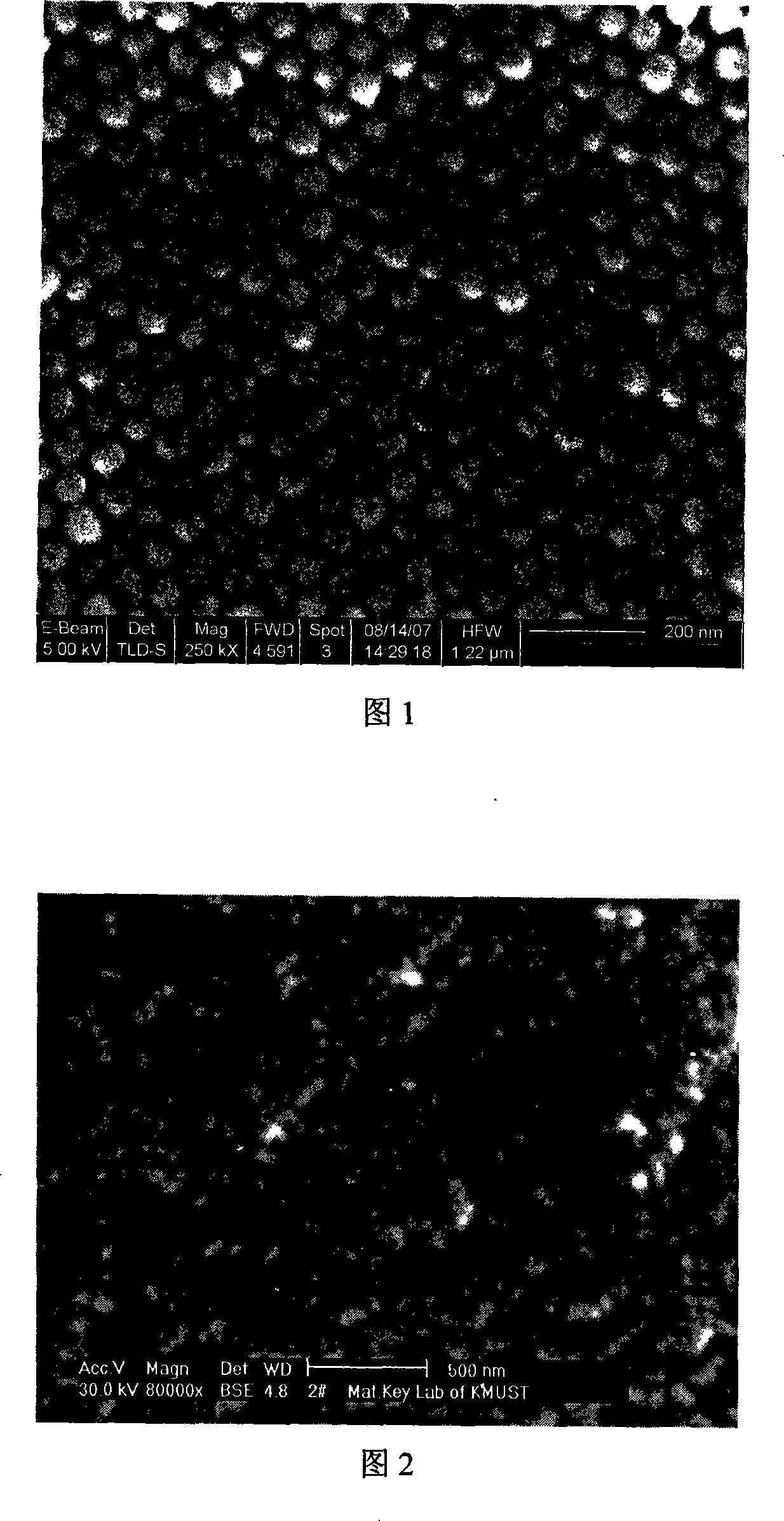

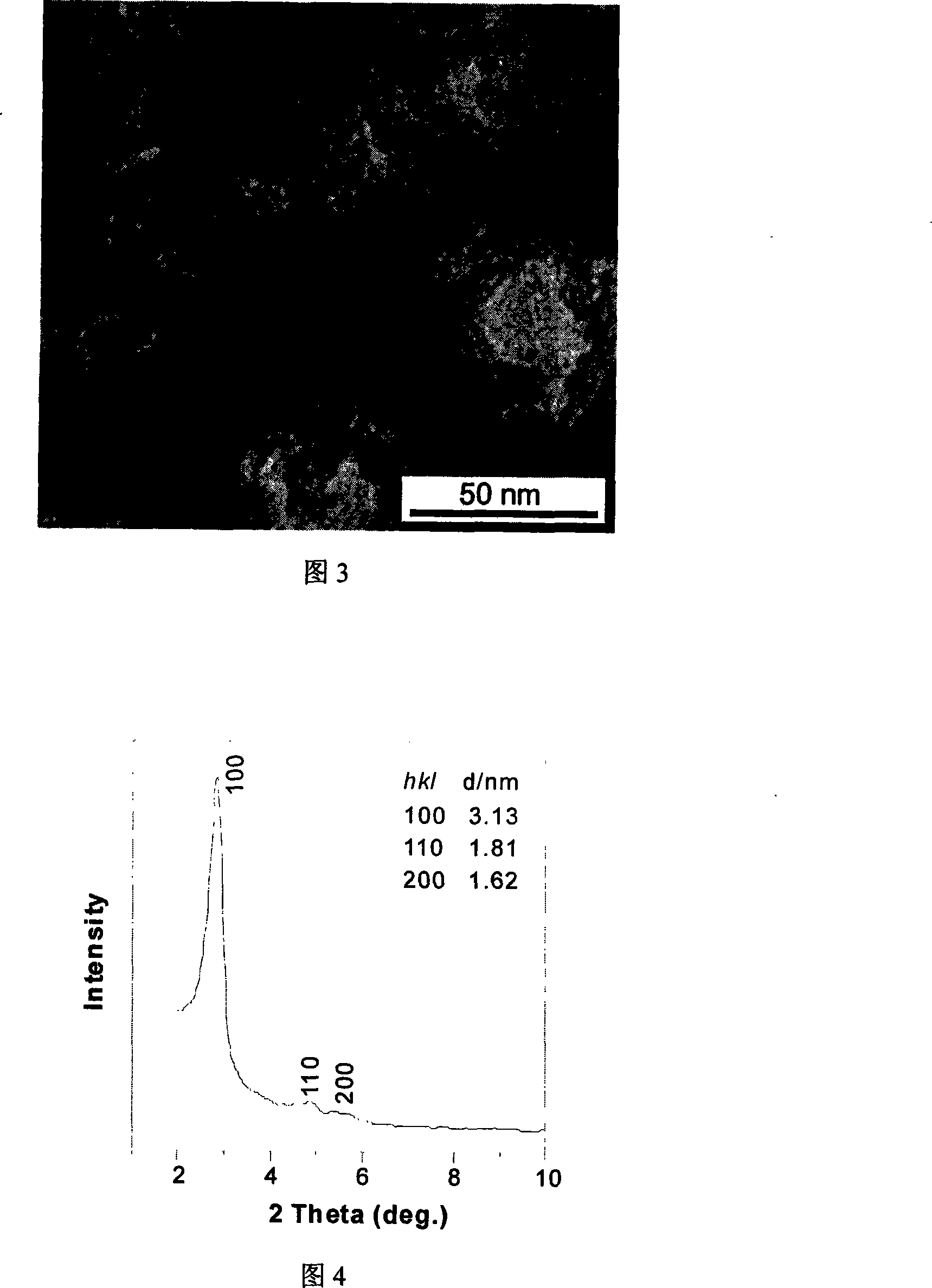

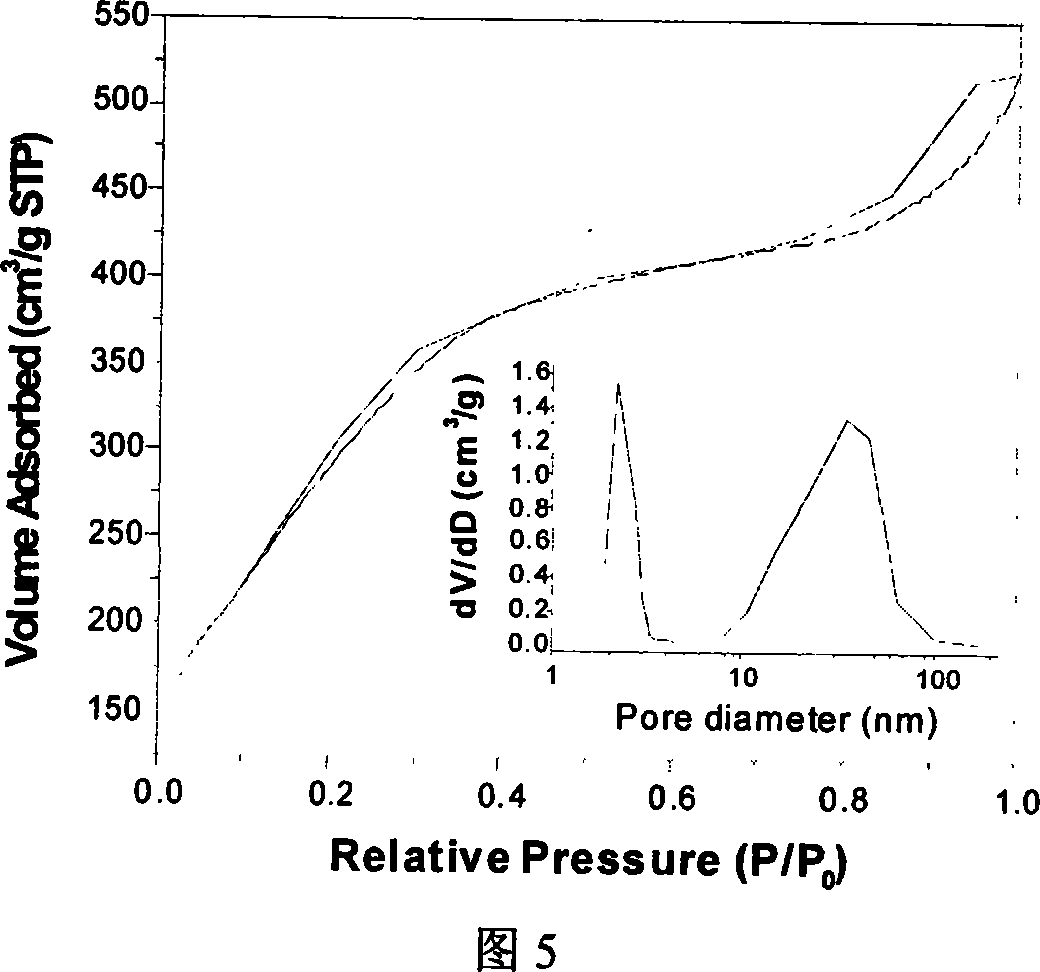

[0030]The ordered double mesoporous silica material of the present invention utilizes ethyl orthosilicate and 1-hexadecyl-3-methylimidazole chloride in an acidic aqueous solution of monodisperse polymethyl methacrylate microcolloidal emulsion balls The self-assembly in the material is obtained by rapid decompression suction filtration and roasting to remove the organic template. The material has large mesoporous pores with a pore size of 38±2nm, and the pore wall is composed of hexagonal phase small mesoporous silica of 2.7±2nm. The characteristic of double mesoporous structure arranged in three-dimensional direction; the material is obtained by the following steps:

[0031] a. Add 0.15g SDS to 175mL distilled water, add 15mL methyl methacrylate monomer under magnetic stirring, feed nitrogen into the solution for more than 20 minutes, to remove the polymerization inhibitor, 0.1164g potassium persulfate initiator Dissolve in 20mL of distilled water, then add to the solution, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com