Method for manufacturing a hybrid microlens

A technology of micro-lens and light guide plate, applied in the field of micro-molding, can solve problems such as not being able to obtain a uniform structure easily, and achieve the effect of reducing production time and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0033] In the following description, detailed descriptions of known related functions and configurations may be omitted to avoid unnecessarily obscuring the subject matter of the present invention.

[0034] In addition, the terms used in the description are defined in consideration of the functions of the present invention, and these terms may be changed according to the user's or operator's intention or customary habits. Therefore, definitions should be made based on the entire specification.

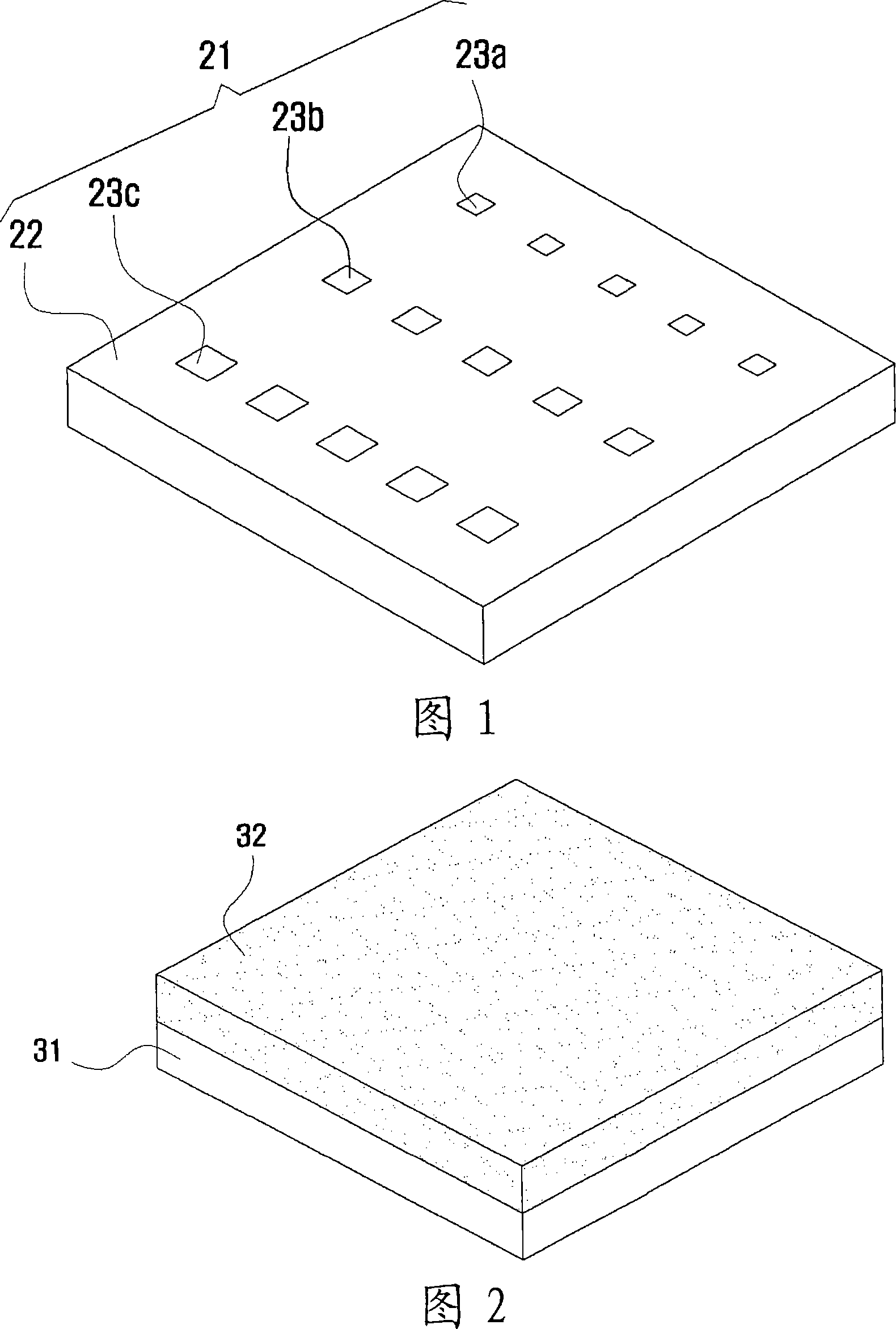

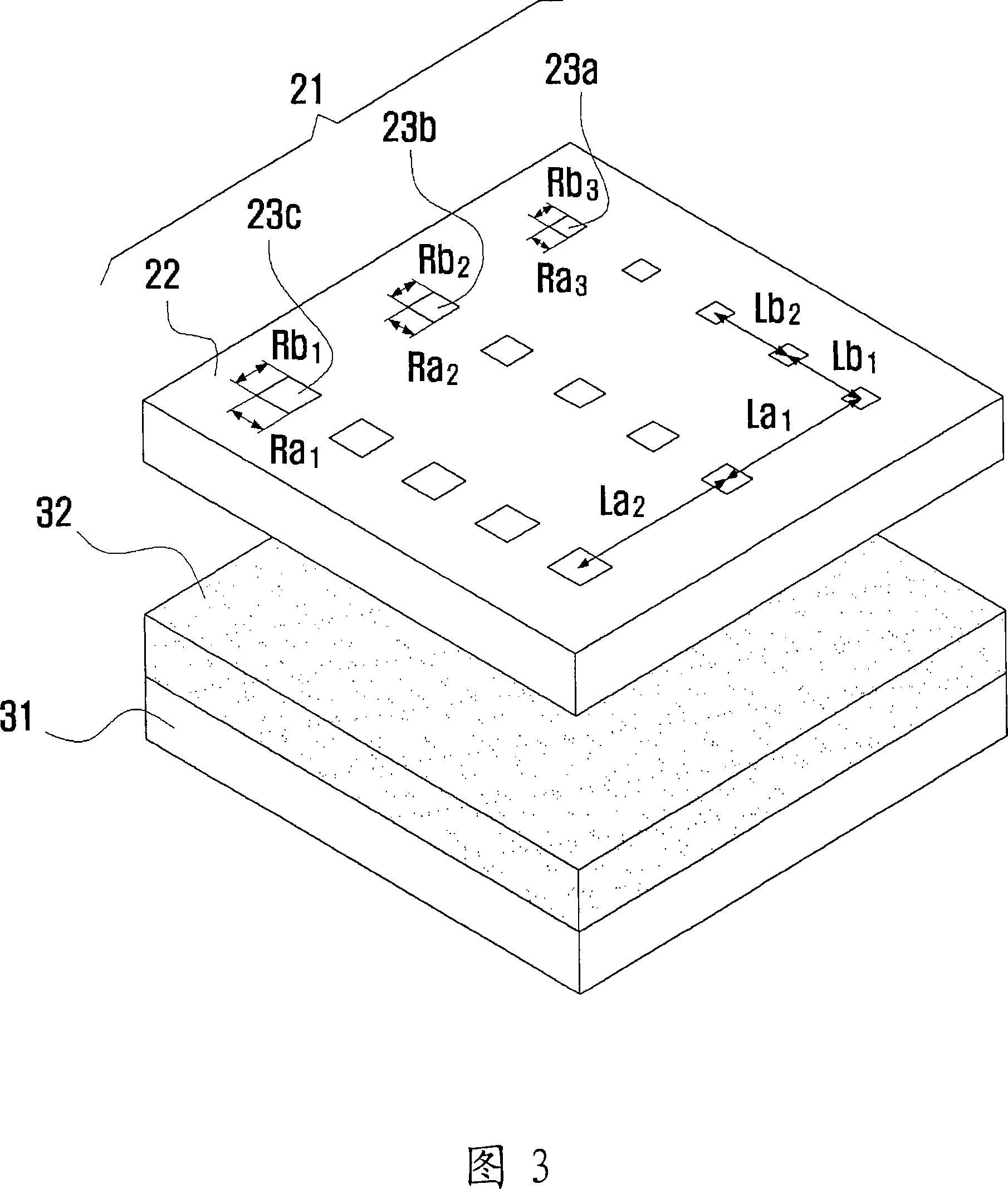

[0035] In the present invention, a mask 21 to be used for exposure processing as shown in FIG. 1 is manufactured first. Here, as for the mask, a thin film mask or a chrome mask can be used depending on the precision of the pattern. In the case of using a chromium mask, the mask can be manufactured with an accuracy of about 1 μm.

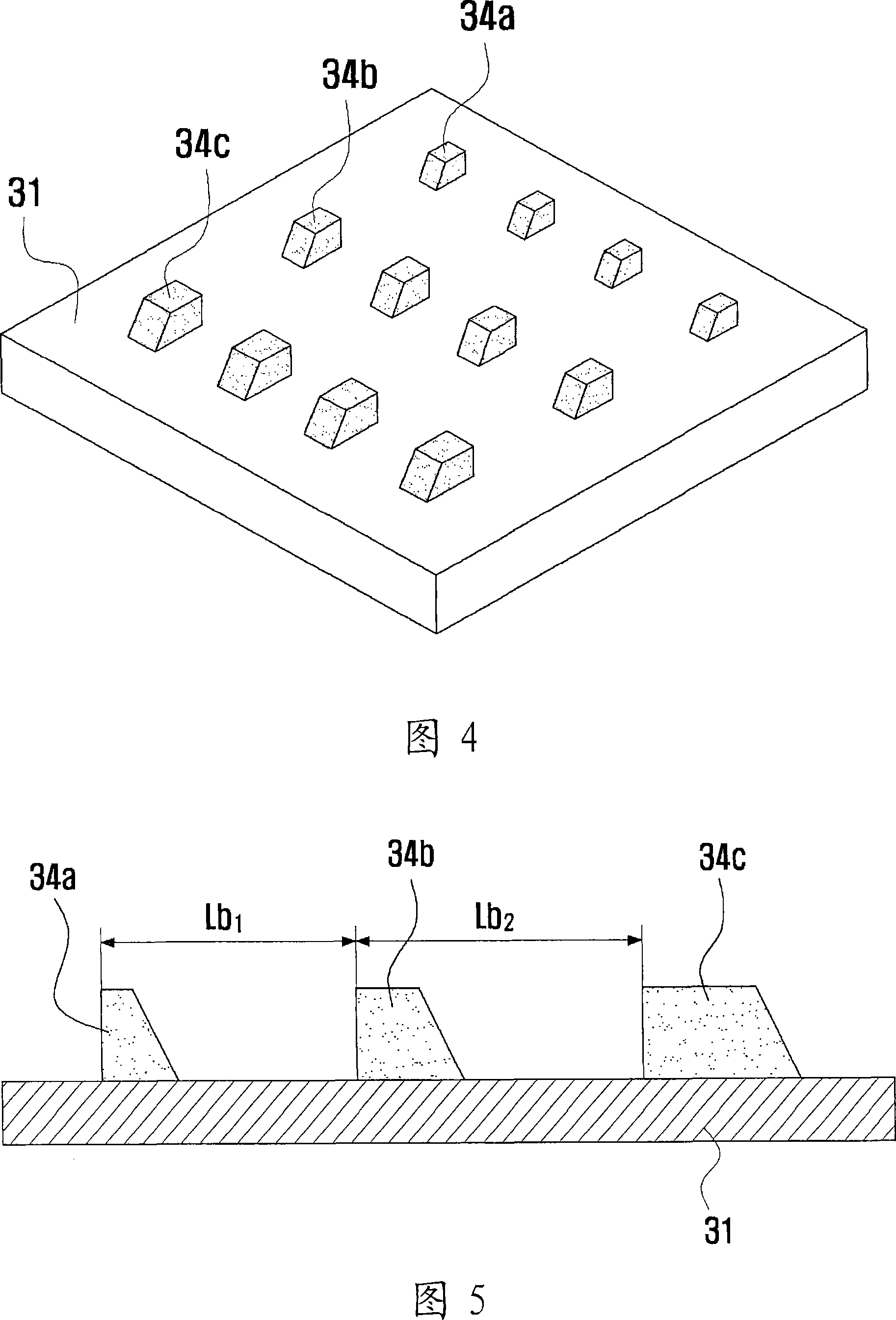

[0036] FIG. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com