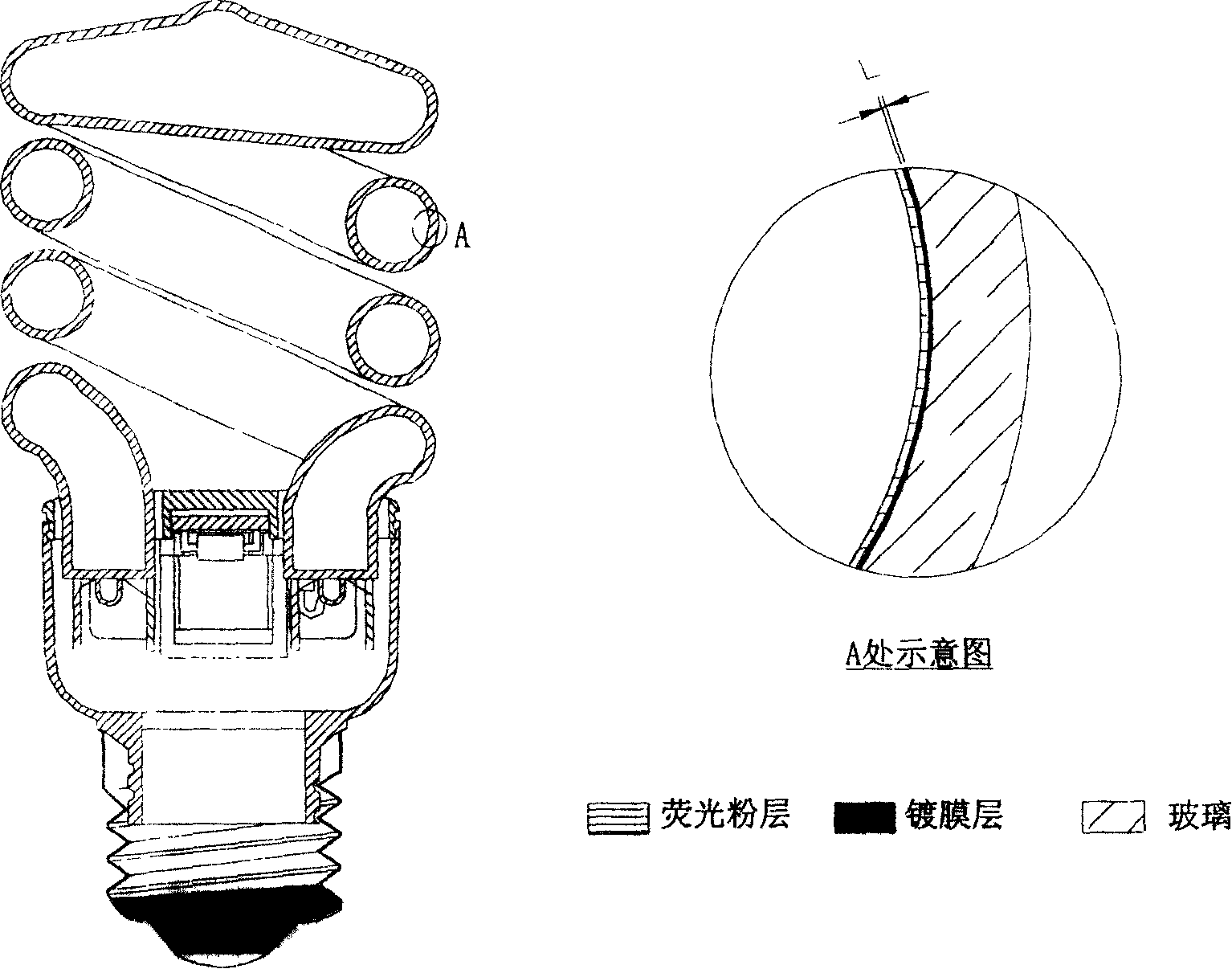

Inner wall coating fluorescent lamp tube

A fluorescent tube and coating technology, which is applied in the field of fluorescent tubes, can solve problems such as insufficient excitation of phosphor particles, unsatisfactory coating effect on the inner wall of alumina, and reduced lumen output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0005] Embodiment 1: choose 10nm titanium dioxide and dilute to 4% coating with pure water, bake and solidify. Compared with the commonly used aluminum oxide coating, the lumen maintenance rate of 2000h has increased by 7.8%, and the coating thickness has been measured to be 1.3μm.

Embodiment 2

[0006] Embodiment 2: choose 50nm titanium dioxide and dilute to 5% coating with pure water, bake and solidify, and repeat coating once. Compared with the commonly used aluminum oxide coating, the lumen maintenance rate of 2000h has increased by 7.4%, and the coating thickness has been measured to be 1.0μm.

Embodiment 3

[0007] Embodiment 3: choose 80nm titanium dioxide and dilute to 6% coating with pure water, solidify. Compared with the commonly used aluminum oxide coating, the lumen maintenance rate of 2000h has increased by 7%, and the coating thickness has been measured to be 0.8μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com