Method and correlated device for confirming optimum object plane and optimum image plane of photo-etching projection device

A technology of lithographic projection and projection objective lens, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, etc., can solve the problem that the best image plane or object plane of projection objective lens, and the accuracy of object plane or image plane cannot be guaranteed. and other problems, to achieve the effect of easy online implementation, low cost and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

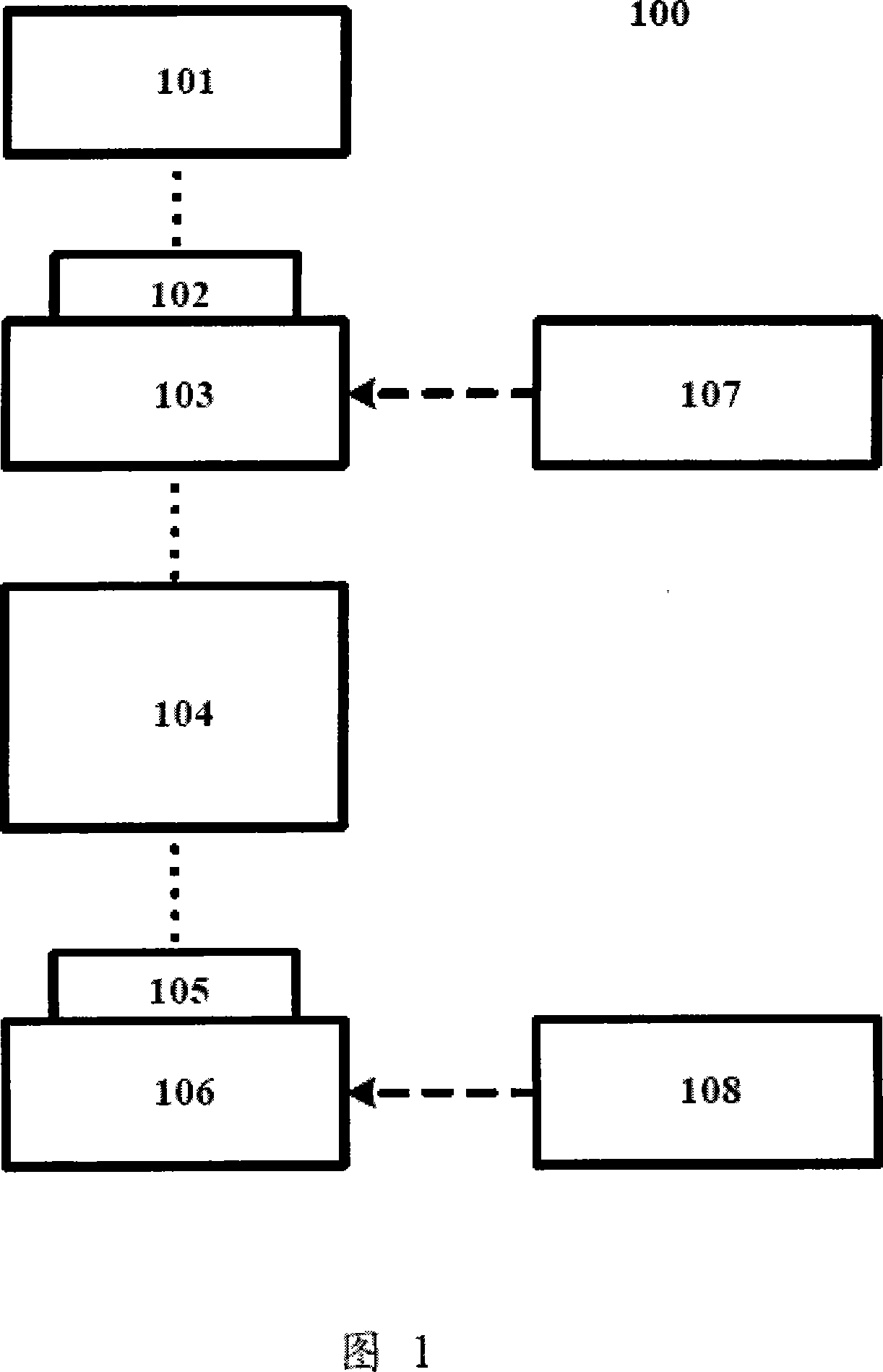

[0026] FIG. 1 is a schematic diagram of the structure of a photolithographic projection device. The lithography projection apparatus 100 includes a light source 101 , a projection objective lens 104 , a mask table 103 and a mask plate 102 thereon, a workpiece table 106 and a wafer 105 thereon. The light source 101 is used to generate a projection light beam. After the projection beam irradiates the mask plate 102 held by the mask table 103 , the circuit pattern on the mask plate 102 is imaged in the photoresist on the upper surface of the wafer 105 through the projection objective lens 104 . After the exposed wafer 105 undergoes a chemical treatment process, the pattern on the mask plate 102 is transferred to the photoresist on the surface of the wafer 105 . The lithography projection apparatus 100 further includes a mask stage motion cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com