Production method of precipitation hardening stainless steel precision strip steel for precision electronic products

A production method, stainless steel technology, applied in the direction of furnace type, furnace, heat treatment equipment, etc., can solve the problems that cannot meet the needs of the precision electronics industry, and achieve the effects of high level of dimensional precision control, stable production, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

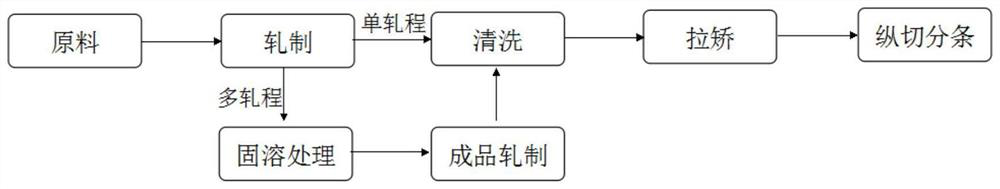

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: Thickness 0.1-0.4mm, the situation of Vickers hardness HV400-450

[0077] The thickness of the target finished product is 0.15mm, the steel type is SUS631, and the hardness requirement is 400-430HV. The SUS631 cold-rolled stainless steel coil with a thickness of 0.6mm and a width of 600mm is selected as the raw material, and the thickness of the finished steel strip after double-pass cold rolling is 0.15mm.

[0078] First, the stainless steel cold-rolled coil raw material with a thickness of 0.6mm is rolled by a four-column 20-high rolling mill, and rolled to 0.22mm after 5 passes, of which the deformation in the first pass is 18%, the deformation in the middle pass is 10%, and the last pass The first deformation amount is 9%, the first pass uses sandblasting rolls for the work rolls, and the other passes use Ra0.4μm rough rolls for rolling.

[0079] After the completion of the first rolling process, the steel coil is subjected to solution treatment in th...

Embodiment 2

[0089] Embodiment 2: Thickness 0.1-0.4mm, the situation of Vickers hardness HV350-400

[0090] The thickness of the target finished product is 0.4mm, the steel type is SUS631, and the hardness requirement is 350-400HV. The SUS631 cold-rolled stainless steel coil with a thickness of 1.2mm and a width of 600mm is selected as the raw material, and the thickness of the finished steel strip after double-pass cold rolling is 0.4mm.

[0091] First, the stainless steel cold-rolled coil raw material with a thickness of 1.2mm is rolled by a four-column 20-high rolling mill, and rolled to 0.54mm after 5 passes, of which the deformation in the first pass is 21%, and the deformation in the second and third passes is 15%. , the deformation amount of the fourth pass is 12%, and the deformation amount of the last pass is 9%. The working rolls of the first pass are sandblasting rolls, and the other passes are rolled with rough rolls of about Ra0.4μm.

[0092] After the first rolling process i...

Embodiment 3

[0102] Embodiment 3: Thickness 0.1-0.4mm, Vickers hardness HV450 above the situation

[0103] The thickness of the target finished product is 0.15mm, the steel type is SUS631, and the hardness is required to be above HV450. The SUS631 cold-rolled stainless steel coil with a thickness of 0.6mm and a width of 600mm is selected as the raw material, and the thickness of the finished steel strip after double-pass cold rolling is 0.15mm.

[0104] First, the stainless steel cold-rolled coil raw material with a thickness of 0.6mm is rolled by a four-column twenty-high rolling mill, and rolled to 0.3mm after 5 passes, of which the deformation in the first pass is 21%, and the deformation in the second, third and fourth passes 11%, and the deformation amount in the last pass is 7.7%. The work rolls in the first pass use sandblasting rolls, and the other passes use rough rolls with Ra0.4μm or so.

[0105] After the first rolling process is completed, the steel coil is subjected to solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com