Making method for niobium-magnesium acid lead-Ti acid lead iron electric thin film with self-polarization effect

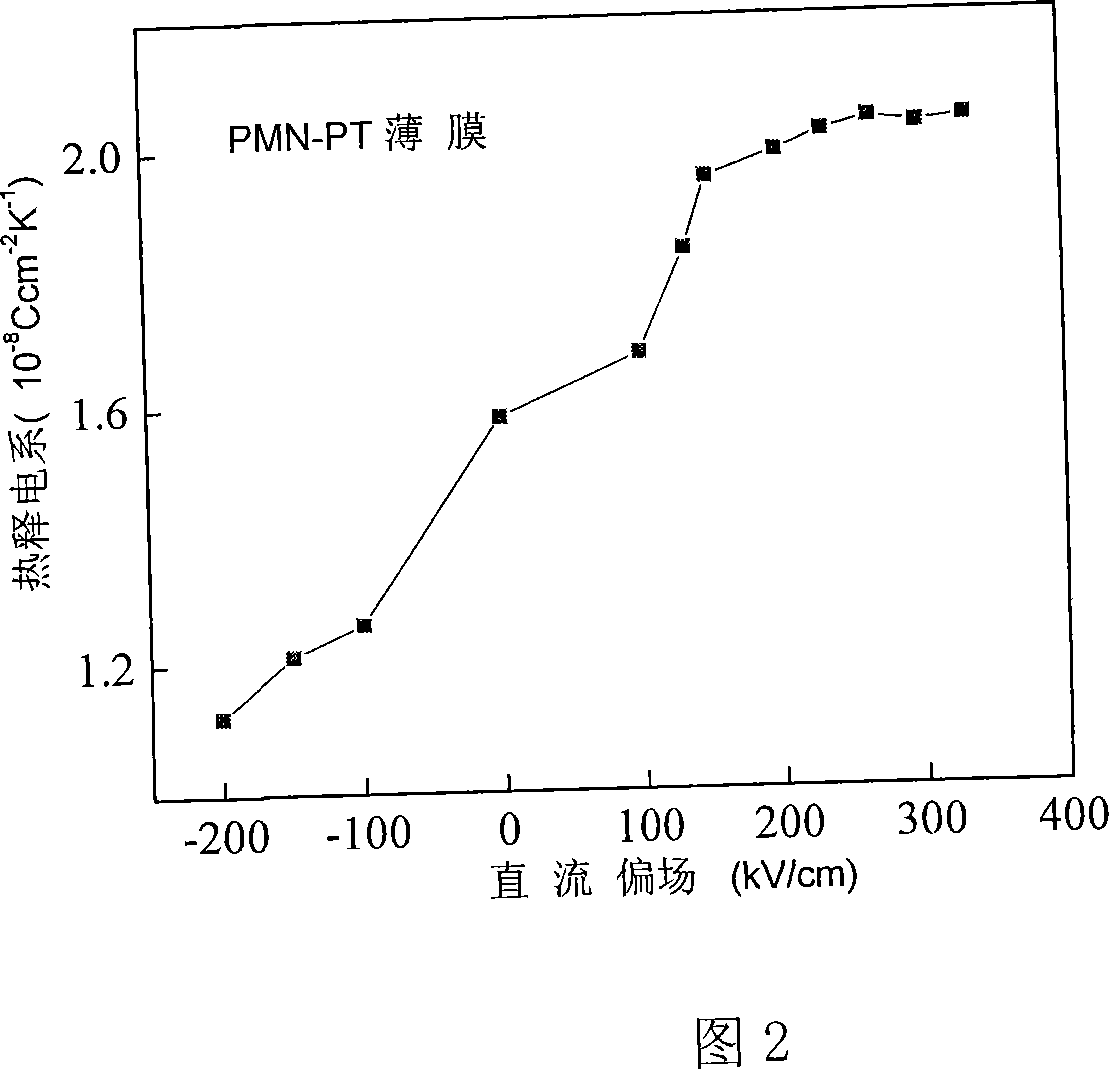

A technology of lead magnesium niobate and ferroelectric thin film, applied in the field of preparation of lead magnesium niobate-lead titanate relaxor ferroelectric thin film material, can solve the problem that the self-polarization effect is not strong enough, the pyroelectric effect needs to be improved, etc. problem, to achieve the effect of high self-heating discharge coefficient, low cost and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below by preferred embodiment and accompanying drawing

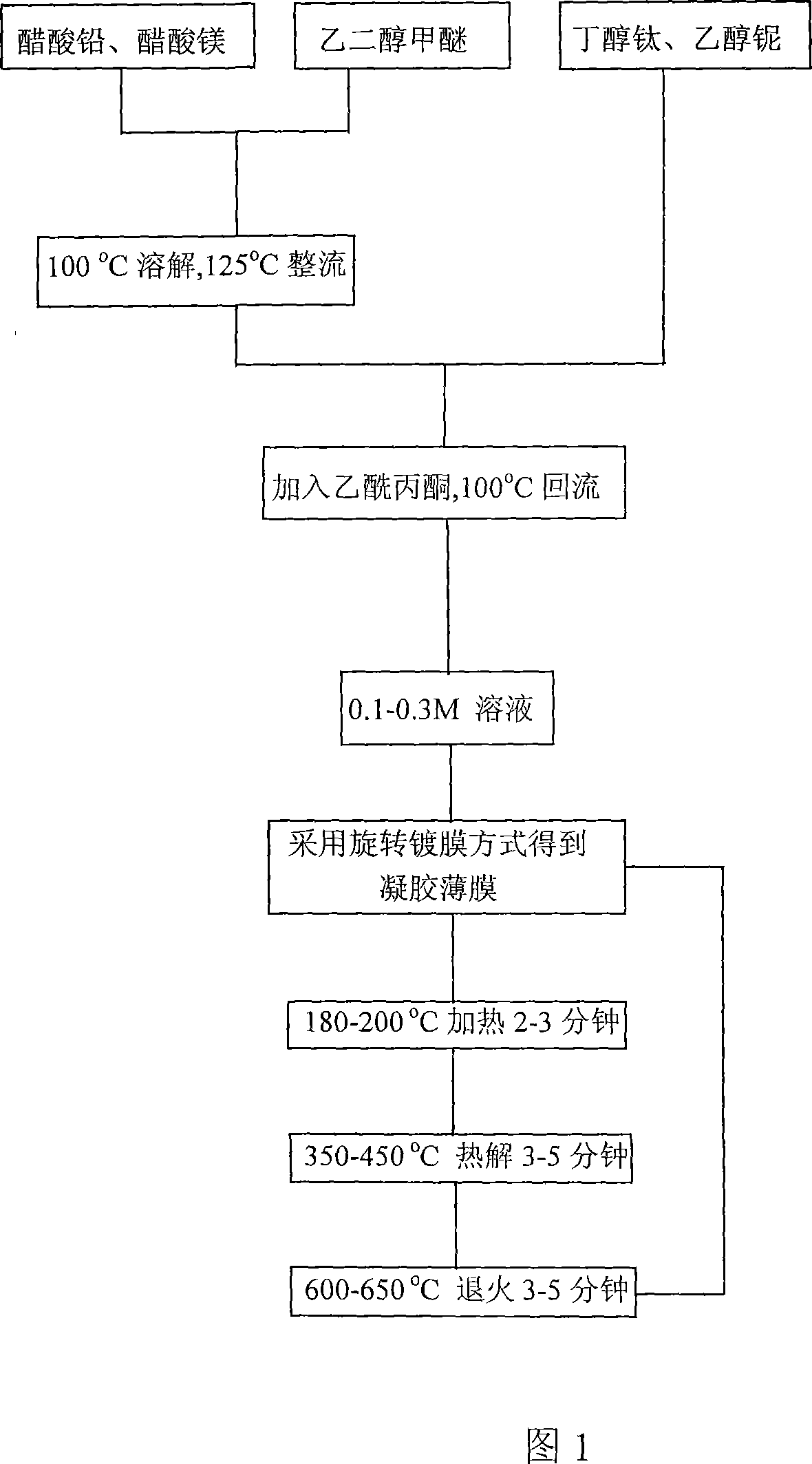

[0025] 0.7Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -0.3PbTiO 3 Preparation of precursor solution with stoichiometric ratio

[0026] Weigh 0.0106 moles of lead acetate and 0.00233 moles of magnesium acetate in a 100ml flask, add 60ml of ethylene glycol methyl ether, and then heat at 100°C to dissolve them. Partial fractions were distilled off at 125°C. After cooling to room temperature, 0.003 mol of titanium n-butoxide, 0.00466 mol of niobium ethoxide and 0.6 ml of acetylacetone were added. Reflux at 100°C for 1 hour. Finally, the obtained precursor solution was filtered through a 0.2 μm microporous filter, and its concentration was adjusted to 0.3 M by evaporating part of the solvent.

[0027] Thin film preparation and crystallization

[0028] The thin film adopts the spin-coating method. Take about 0.5ml of the precursor solution with a rubber dropper and drop it on the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com