Mine working face cooling system

A technology for working face and mine, which is applied in the field of cooling system for mine working face, can solve the problems of low reliability, low efficiency, large investment, etc., and achieve the effects of high reliability, reduction of times, and reduction of heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

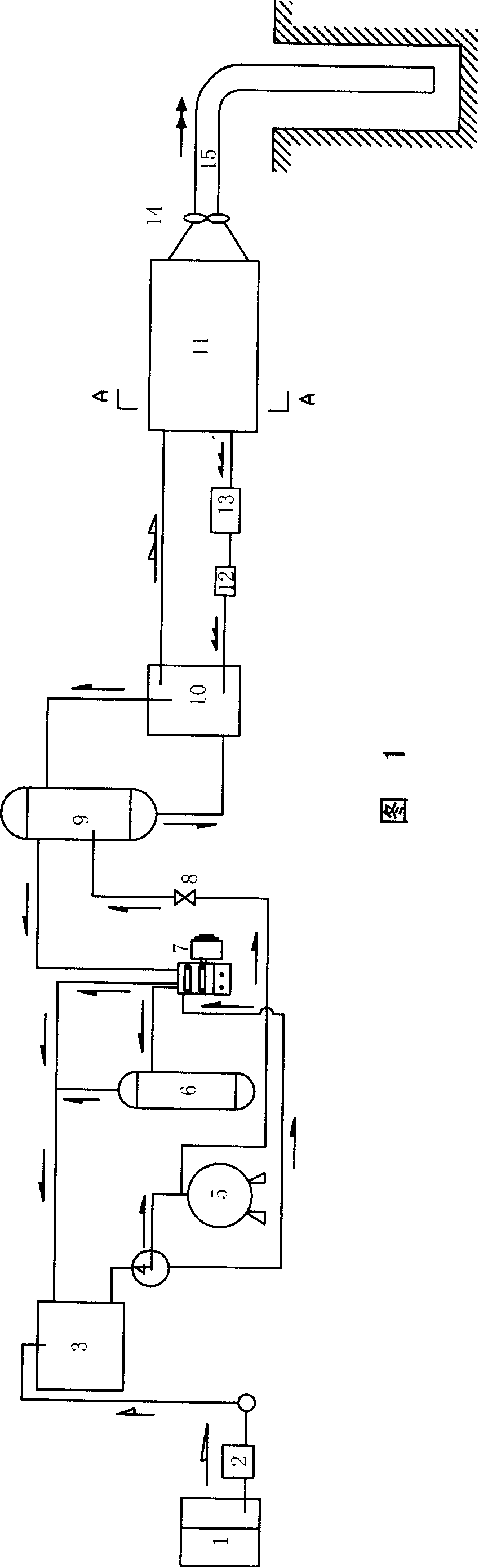

[0016] The mine working face cooling system of the present invention, also known as the underground working face spray air-cooled cooling system, produces refrigerant water through the ammonia refrigeration unit in the ground centralized machine room, and makes the refrigerant water spray air flow in the spray air chamber to prepare cold air. Then use the fan to send the cold air to the mine working face to cool down through the air supply pipeline.

[0017] The composition of the mine face cooling system of the present invention is shown in FIG. 1 . The system is mainly composed of a ground ammonia refrigeration unit and its cooling water circulation equipment, a device that uses refrigerant water to prepare cold air - a spray air chamber, a cold air delivery fan and an air supply pipeline. That is, it includes ammonia circulation system, cooling water circulation system, refrigerant water circulation system, and cold air delivery facilities. The single arrows, hollow single...

Embodiment 2

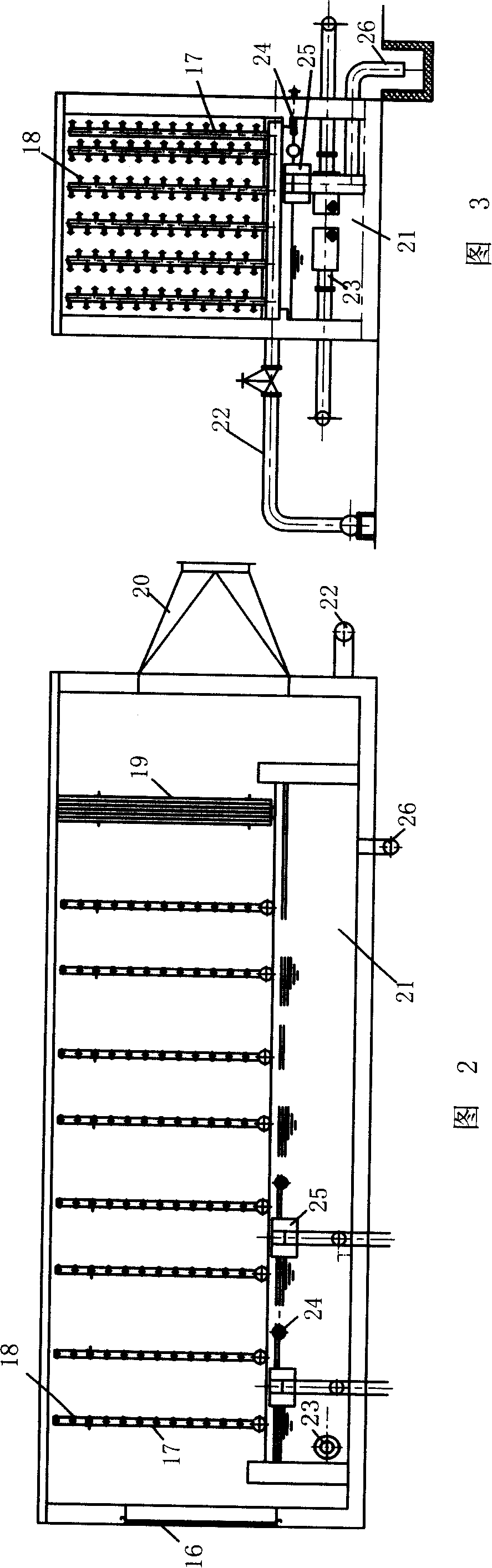

[0027] The cooling system of the working face of the mine can also adopt a multi-stage series surface cooler to replace the spray air chamber as the cold air preparation device. There are at least three stages in series. The surface cooler can be used: KL-2-6×22×1500 type, product of Shanghai Xinzhong Heating and Cooling Equipment Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com