Compound timber corrosionproof process liquid, its preparing method and method for modifying timber using the process liquid

A wood preservative and treatment liquid technology, which is applied in the direction of wood impregnation, impregnated wood, wood processing utensils, etc., can solve the problems of vulnerability to environmental and microbial damage, human health and environmental safety hazards, and large variation in material properties. Cold water loss resistance, good fixation effect, and the effect of increasing the average weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The wood to be treated is selected from the sapwood of Chinese fir (Cunninghamia lanceolata), collected from Sichuan, and made into a cube of 19mm (L) × 19mm (T) × 19mm (R), with a diameter of 50mm and a thickness of 1.4mm. (L)×35mm(T)×5mm(R) cuboid three different specifications to be processed.

[0039] Prepare composite wood preservative treatment liquid of the present invention and impregnate wood according to the following steps:

[0040] 1. Preparation of materials:

[0041] 1000 g of sodium montmorillonite (Na-MMT) with 200 mesh and cation exchange capacity (CEC) of 100 mmol / 100 g; cetyltrimethylammonium bromide (CTMAB) with cation exchange capacity 1.5 times that of montmorillonite; A 70% solution of dimethyl didecyl ammonium chloride (DDAC).

[0042] 2. Disperse the sodium-based montmorillonite into a water suspension with a mass percentage of 5% (W / W), stir for 3 hours to disperse evenly, and then let it stand for aging. The aging time is not less than 1 hou...

experiment example 1

[0056] Carry out weight gain rate analysis to the wood that embodiment 1 and comparative example 1, 2 process.

[0057] As shown in table 1, the average weight gain rate of the wood / montmorillonite composite material processed by the composite wood preservative treatment liquid of embodiment 1 is significantly higher than the wood test material processed by the single component DDAC preservative liquid at the same concentration The average weight gain rate indicates that the organic montmorillonite has entered the wood along with the DDAC preservative solution, so that the weight gain rate of the composite material is obviously higher.

[0058] Table 1 Weight gain rate of different treatment test materials

[0059]

experiment example 2

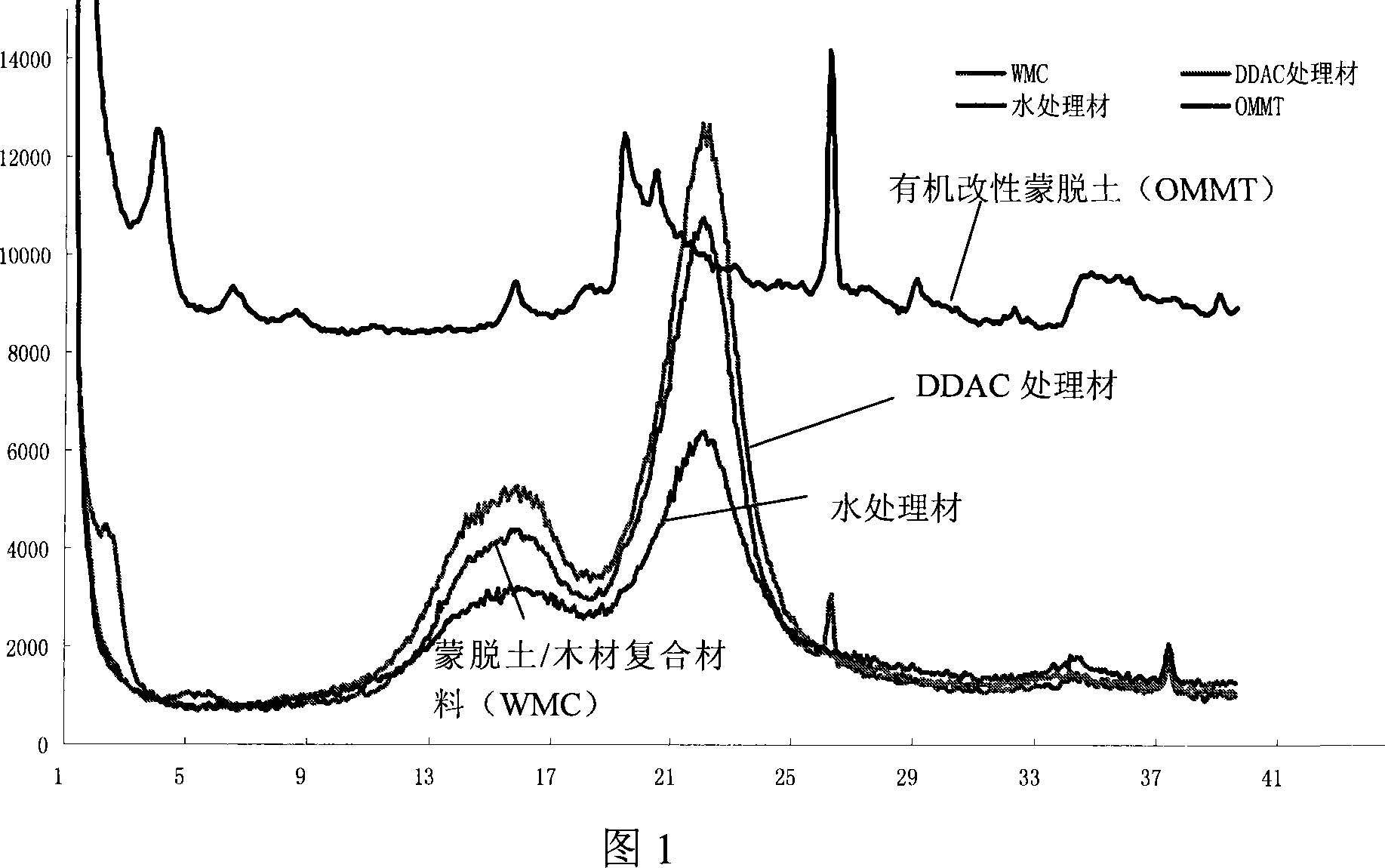

[0061] Carry out X-ray diffraction analysis to the wood treated in Example 1 and Comparative Examples 1 and 2.

[0062] The X-ray diffractometer is XRD-6000 produced by Shimadzu Corporation of Japan. The test conditions are: continuous spectrum scanning, CuKa copper target radiation (λ=0.154mm), radiation tube current 30mA, tube voltage 40kV, scanning range 2θ=1.5~40, step size 0.1°, scanning speed Vt=2° / min.

[0063] The XRD analysis results of the DDAC and organomontmorillonite composite liquid treatment material of embodiment 1, the distilled water blank treatment material of organomontmorillonite and comparative example 1, and the DDAC treatment material of comparative example 2 are shown in Fig. The surface characteristic diffraction peak positions are shown in Table 2

[0064] Table 2 The positions of characteristic diffraction peaks of different treated materials on the 001 crystal plane

[0065]

Measurement parameters

MMT

CTMAB m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com