LD terminal pump Nd:YAG/SrWO4/KTP yellow light laser

A laser and yellow light technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of small nonlinear coefficient, high price, and large volume, and achieve stable performance, low cost, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

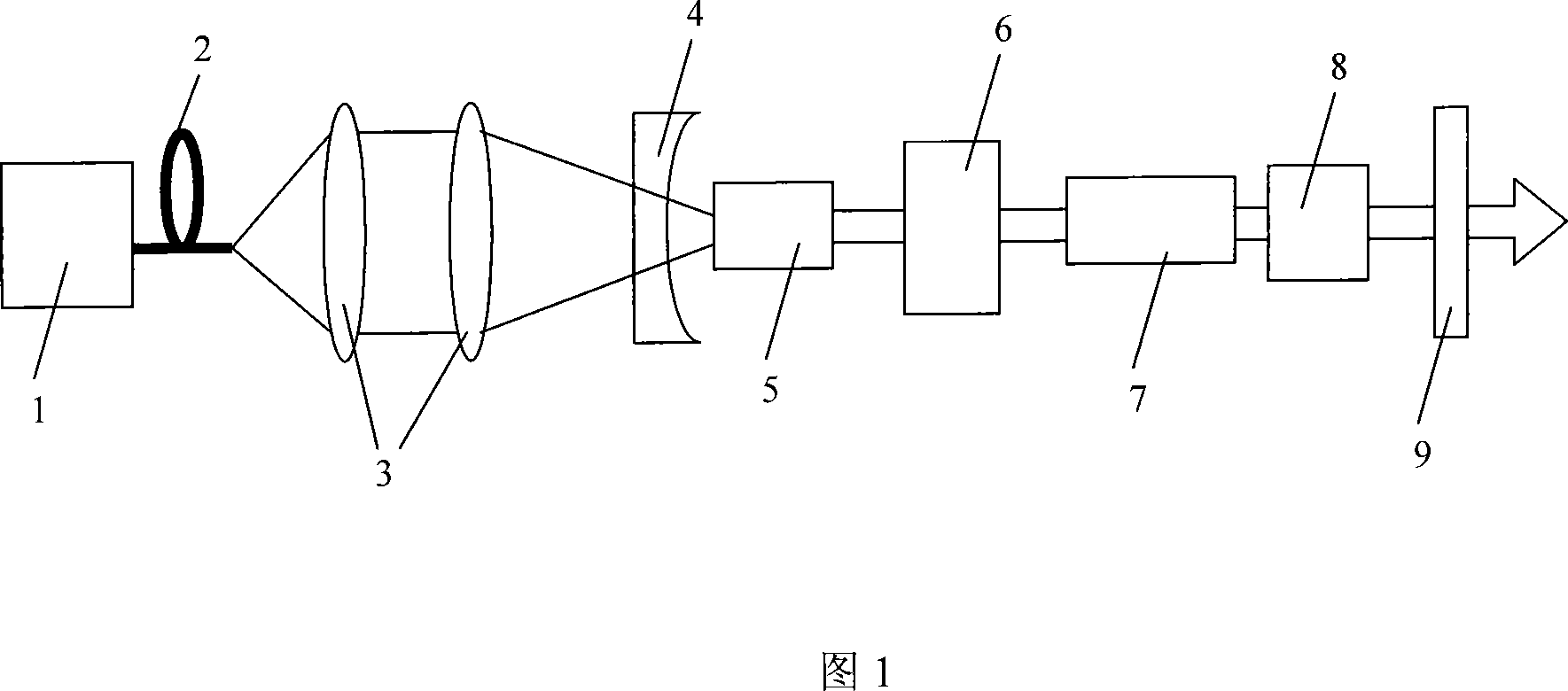

[0020] As shown in Figure 1, the device of the present invention includes a laser diode LD end pump source 1, an optical fiber 2, a coupling lens 3, a resonant cavity, a neodymium-doped yttrium aluminum garnet Nd:YAG crystal 5, an acousto-optic Q-switching device 6, and tungstic acid Strontium SrWO 4 Crystal 7 and potassium titanyl phosphate KTP crystal 8; the pump light emitted by LD end-face pump source 1 enters the resonant cavity through optical fiber 2 and coupling lens 3, which is characterized in that the resonant cavity is composed of rear cavity mirror 4 and output mirror 9 , the front end is the rear cavity mirror 4, the rear end is the output mirror 9, and the neodymium-doped yttrium aluminum garnet Nd:YAG crystal 5, the acousto-optic Q-switching device 6, the strontium tungstate SrWO 4 Crystal 7 and potassium titanyl phosphate KTP crystal 8; the above crystals are surrounded by metal blocks with through holes and pipes, the crystals are placed in the through holes ...

Embodiment 2

[0031] Same as embodiment 1, except that the RF wave modulation frequency of the acousto-optic Q-switching device 6 is 15KHz; the radius of curvature of the rear cavity mirror 4 is 1000mm; the Nd-doped yttrium aluminum garnet Nd:YAG base The doping concentration of frequency crystal 5 is 1%.

[0032]The working process of the laser: the 808nm pump light emitted by the LD end pump source 1 enters the neodymium-doped yttrium aluminum garnet Nd:YAG crystal 5 through the optical fiber 2 and the coupling lens 3, when the Q switch of the acousto-optic Q switch device 6 is turned off , the pump light is converted into inverted particles and stored; when the Q switch is turned on, a large number of accumulated inverted particles are instantly converted into 1064.2nm fundamental frequency light through stimulated radiation; the fundamental frequency light with higher peak power passes through strontium tungstate wxya 4 The crystal 7 is transformed into 1179.6nm Raman light due to stim...

Embodiment 3

[0034] Same as embodiment 1, except that the RF wave modulation frequency of the acousto-optic Q-switching device 6 is 25KHz; the radius of curvature of the rear cavity mirror 4 is 1000mm; the Nd-doped yttrium aluminum garnet Nd:YAG base The doping concentration of frequency crystal 5 is 1.2%.

[0035] The working process of the laser: the 808nm pump light emitted by the LD end pump source 1 enters the neodymium-doped yttrium aluminum garnet Nd:YAG crystal 5 through the optical fiber 2 and the coupling lens 3, when the Q switch of the acousto-optic Q switch device 6 is turned off , the pump light is converted into inverted particles and stored; when the Q switch is turned on, a large number of accumulated inverted particles are instantly converted into 1064.2nm fundamental frequency light through stimulated radiation; the fundamental frequency light with higher peak power passes through strontium tungstate wxya 4 The crystal 7 is transformed into 1179.6nm Raman light due to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com